What is Dual Injection Molding

Dual Injection Molding, also known as Two - Shot Plastic Injection Molding, is an advanced manufacturing process that combines two different materials in a single operation to create a single, unified product. This innovative technique has gained significant traction across various industries due to its ability to enhance product functionality, aesthetics, and performance.

In a traditional injection molding process, a single type of plastic material is melted and injected into a mold cavity. However, dual injection molding takes it a step further. It involves using a specialized injection molding machine equipped with two or more injection units. Each injection unit is responsible for melting and injecting a different material.

The Process in Detail

- First Shot: The first material is injected into the mold cavity. This initial material forms the base or the primary structure of the final product. For example, in the production of a toothbrush, the first shot could be a hard plastic for the handle. The mold closes around the injected material, and it cools and solidifies, taking the shape of the first - part mold cavity.

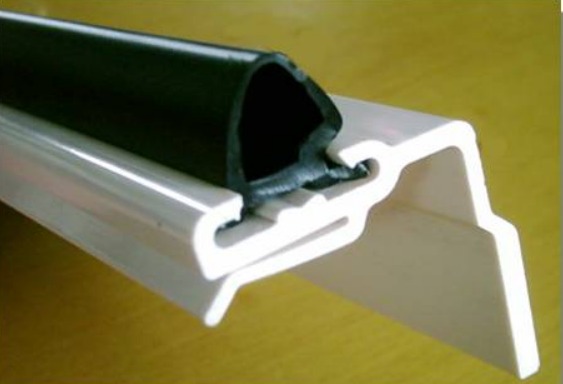

- Second Shot: After the first material has solidified, the mold either rotates, slides, or is reconfigured in some way to expose the already - formed first - shot part to a new injection unit. Then, the second material is injected. Continuing with the toothbrush example, the second shot could be a soft rubber for the grip area. The second material bonds with the first - shot material during the injection process, creating a seamless and integrated product.

The two materials can be different types of plastics, such as a combination of a rigid thermoplastic like acrylonitrile - butadiene - styrene (ABS) and a flexible thermoplastic elastomer (TPE). They can also vary in color, allowing for the creation of multi - colored products without the need for additional painting or decoration processes. This not only simplifies the manufacturing process but also reduces production time and cost.

The Process Step by Step

Material Preparation

Before starting the dual injection molding process, meticulous material preparation is essential. First, two different plastic materials are selected based on the product's requirements. For example, if you need a product with a hard outer shell and a soft, grippy inner layer, you might choose a rigid plastic like polycarbonate (PC) for the outer part and a thermoplastic elastomer (TPE) for the inner layer.

These materials often require pre - treatment. Drying is a common step, especially for hygroscopic plastics such as nylon. Moisture in the plastic can cause defects like voids, bubbles, or poor surface finish during the molding process. Plastics are typically dried in a desiccant dryer at specific temperatures and for a set amount of time. For instance, nylon may need to be dried at around 80 - 100°C for 4 - 6 hours.

Some materials may also benefit from pre - heating. Pre - heating can reduce the energy required to melt the plastic during injection and improve its flow characteristics. This can lead to better filling of the mold cavity and more consistent part quality.

Machine Setup

A dual injection molding machine is a specialized piece of equipment with unique features. It is equipped with two injection units, each having its own hopper, screw, and barrel. The first injection unit is responsible for melting and injecting the first material, while the second unit deals with the second material.

The machine also has a sophisticated mold - handling system. One common setup is a rotary mold. The rotary mold is mounted on a turntable that can rotate 180 degrees or more. This allows the mold to be positioned in front of each injection unit in sequence. When the first material is injected and has solidified to a certain extent, the mold rotates, presenting the partially - formed part to the second injection unit.

There are also other mold - movement mechanisms, such as slide - type molds. In a slide - type mold setup, the mold halves can slide horizontally or vertically to expose the first - shot part to the second injection operation. Precise control systems are in place to ensure accurate positioning of the mold and consistent injection parameters for both materials.

Injection and Molding

The injection and molding stage is where the magic of dual injection molding happens. First, the first plastic material, which has been properly prepared and is in a molten state, is injected into the mold cavity. The injection pressure, speed, and temperature are carefully controlled. High - pressure injection is often used to ensure that the molten plastic fills every detail of the mold cavity quickly and completely. For example, in the production of a complex - shaped automotive interior component, the first - shot material (say, a rigid ABS plastic) may be injected at a pressure of 80 - 120 MPa.

Once the first material has filled the cavity, it is allowed to cool and solidify for a short period. This solidification time is crucial; if it's too short, the part may deform during the second - shot injection, but if it's too long, it can increase the overall cycle time. After the appropriate solidification time, the mold moves (either rotates or slides depending on the setup) to the second injection unit.

The second molten plastic material is then injected. The second material bonds with the first - shot material due to the heat of the molten second material and the surface - energy interaction between the two plastics. This bonding creates a strong, integrated part. For example, in the production of a power tool grip, the soft TPE second - shot material bonds firmly with the hard plastic handle (first - shot material), providing a comfortable and non - slip grip. The second - shot injection also has its own set of optimized parameters, including injection pressure, speed, and temperature, which are adjusted according to the material properties and the part design. After the second material is injected and has solidified, the mold opens, and the fully - formed dual - material part is ejected, ready for further post - processing if required.

Applications in Various Industries

Automotive Industry

The automotive industry is one of the major beneficiaries of dual injection molding technology. In car interiors, dual injection molding is used to create components that require a combination of soft and hard materials. For example, steering wheels are often made using this process. The core of the steering wheel is typically made from a rigid plastic like polypropylene (PP) for structural integrity. Then, a layer of soft thermoplastic elastomer (TPE) is injected over it. This soft layer provides a comfortable grip for the driver, reduces hand fatigue during long - distance driving, and also enhances the overall aesthetics of the steering wheel.

Dashboards are another area where dual injection molding shines. The main body of the dashboard is usually a hard plastic that can withstand the mechanical stresses within the vehicle. However, areas where the driver may interact directly, such as the edges or control panel surrounds, can be molded with a softer material. This not only gives a more luxurious feel but also reduces the risk of injury in case of an accident.

Exterior components like door handles also utilize dual injection molding. A hard plastic forms the internal structure for strength and durability, while a soft, weather - resistant TPE is added to the outer surface. This soft outer layer provides a better grip, especially in wet conditions, and also helps to prevent scratches on the vehicle's paintwork.

Consumer Electronics

In the consumer electronics sector, dual injection molding has become increasingly popular. Take mobile phone cases as an example. Many high - end phone cases are made using this technique. The inner layer is often a hard plastic, such as polycarbonate (PC), which offers excellent protection against drops and impacts. The outer layer can be a soft, flexible TPE or silicone. This soft outer layer not only improves the grip of the phone, reducing the chances of it slipping out of the user's hand, but also adds a touch of style. Different colors and textures can be achieved through dual injection molding, allowing for a wide range of design options.

Headphone shells are also commonly produced with dual injection molding. The hard inner structure houses the electronic components of the headphones, ensuring their safety and proper functioning. The outer soft layer provides a comfortable fit for the user's ears. It can also be designed to be noise - isolating to some extent, enhancing the audio experience. The ability to combine different materials in one molding process reduces the need for additional assembly steps, which in turn reduces production costs and improves the overall quality of the product.

Medical Devices

The medical device industry has strict requirements for materials, especially in terms of biocompatibility and hygiene. Dual injection molding is used to produce various components in medical devices. For instance, the handles of surgical instruments often require a combination of a hard, strong material for the internal structure and a soft, non - slip material on the outside. A hard plastic like acrylonitrile - butadiene - styrene (ABS) can be used as the base material for its strength and stability. Then, a biocompatible TPE is injected over it. This soft TPE provides a secure grip for surgeons during operations, even when their hands may be wet or slippery due to sterilization fluids.

The outer shells of medical devices such as diagnostic equipment also benefit from dual injection molding. The hard outer shell protects the internal delicate electronics and sensors from physical damage. The inner layer, made of a biocompatible material, ensures that the device is safe for use in a medical environment. It also helps to reduce the risk of contamination as the seamless construction created by dual injection molding minimizes the presence of crevices where bacteria could potentially grow. Additionally, the ability to use different colors for the two materials can be used for color - coding purposes, which is useful for quickly identifying different parts or functions of the medical device.

Yigu Technology's View

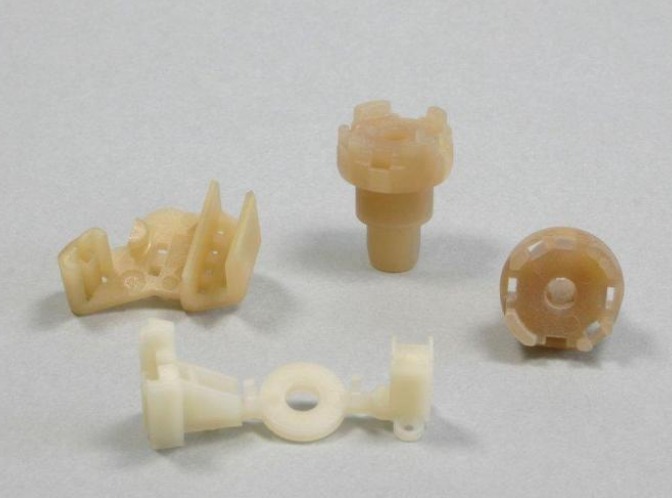

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in dual injection molding. In actual production, we've found that this technology can significantly enhance product performance, such as creating products with both rigid and flexible parts. The main advantages lie in reducing assembly steps and improving product aesthetics and functionality. However, challenges do exist, like ensuring the perfect bonding of two materials and dealing with complex mold designs.

To overcome these, we invest in advanced equipment and continuous R & D. Our professional team carefully selects compatible materials and optimizes the injection process parameters. By constantly innovating, we are committed to providing high - quality dual injection molding products to meet diverse customer needs.

FAQ

What types of materials can be used in dual injection molding?

Common materials used in dual injection molding include various plastics. For example, combinations like rigid plastics such as acrylonitrile - butadiene - styrene (ABS), polycarbonate (PC), and polypropylene (PP) can be paired with flexible thermoplastic elastomers (TPEs). ABS is often used for its strength and impact - resistance in the first shot, while TPE provides softness and flexibility in the second shot. Nylon can also be used in the first shot for applications requiring high - strength and heat - resistance, and then combined with a softer material like TPE for better handling or comfort - related features. Additionally, different colors of the same plastic material can be used to create multi - colored products.

How does dual injection molding compare to traditional injection molding in terms of cost?

In terms of cost, dual injection molding generally has a higher initial investment. The equipment for dual injection molding is more complex, with two or more injection units, which are more expensive than a single - unit traditional injection molding machine. The mold design for dual injection molding is also more intricate, leading to higher mold - making costs. However, in the long run, for products that require multiple materials or colors, dual injection molding can reduce assembly costs and production time. Since it combines multiple operations into one, it can eliminate the need for additional post - molding assembly steps. For example, if a product has a soft - touch grip area and a hard body in traditional injection molding, two separate parts would need to be produced and then assembled, which incurs labor and time costs. In dual injection molding, these two parts are created in one operation, potentially offsetting the higher initial investment over a large production run.

What are the key considerations for mold design in dual injection molding?

Mold design in dual injection molding has several key aspects. First, the mold structure needs to be carefully planned to accommodate the movement of the mold between the two injection operations. For a rotary mold, the turntable must be accurately designed to ensure precise positioning in front of each injection unit. The cooling system is crucial as well. Since two materials are being injected, the cooling channels need to be arranged in a way that can effectively cool both materials without causing uneven cooling, which could lead to warping or other defects. Material flow paths also play a vital role. The design should ensure that the first - shot material fills the cavity completely before the second - shot material is injected. And when the second - shot material is injected, its flow should be controlled to bond properly with the first - shot material without causing any flow - related defects such as voids or weld lines.