Introduction

Understanding Precision Machining Parts

In the realm of modern manufacturing, precision machining parts play a pivotal role. Precision machining parts refer to components that are manufactured with an extremely high level of accuracy and tight tolerances. These parts are crafted through advanced machining processes, utilizing state - of - the - art equipment and techniques.

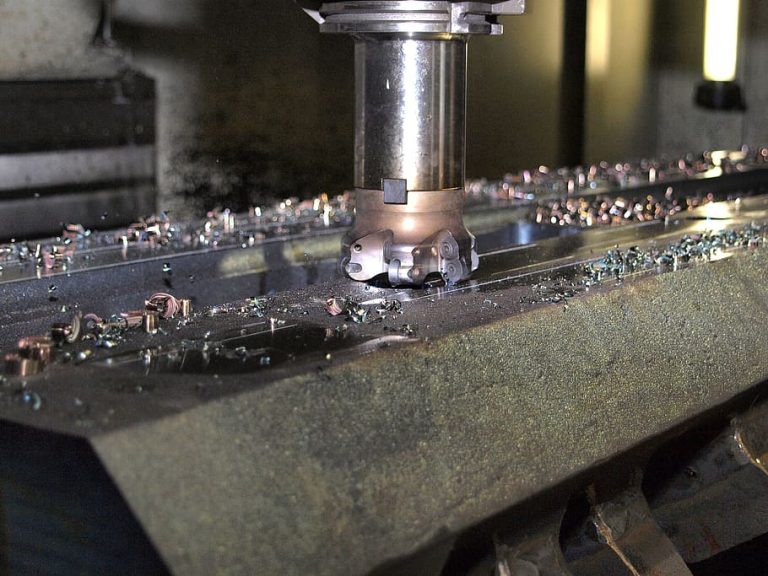

The manufacturing of precision machining parts involves various operations such as milling, turning, drilling, and grinding. Each operation is carried out with meticulous care to ensure that the final product meets the exact specifications required. For Yigu Technology example, in the aerospace industry, precision machining parts for aircraft engines need to have tolerances within a few microns. A single deviation could lead to catastrophic consequences, affecting the performance and safety of the entire aircraft.

In the automotive sector, precision - made engine components contribute to better fuel efficiency and reduced emissions. High - precision gears, for instance, ensure smooth power transmission, enhancing the overall driving experience. These parts are not only about achieving the right dimensions but also about ensuring excellent surface finish, which is crucial for reducing friction and wear in moving parts.

As technology continues to advance, the demand for precision machining parts across different industries is on the rise. From medical devices, where precision is a matter of life and death, to electronics, where miniaturization requires ever - more accurate components, the significance of these parts cannot be overstated. In the following sections, we will delve into the numerous advantages that precision machining parts bring to the manufacturing process.

The Superior Precision Factor

Unmatched Tolerance Control

One of the most remarkable aspects of precision machining parts is their exceptional tolerance control. Tolerance refers to the allowable deviation from a specified dimension. In industries like aerospace, the tolerance requirements are astronomically tight. For Yigu Technology example, parts in a jet engine must have tolerances within the range of ±0.001 inches or even less. A slight deviation can lead to unbalanced rotation, increased fuel consumption, and in extreme cases, engine failure.

Precision machining techniques, such as computer - numerical - control (CNC) machining, enable manufacturers to achieve these minuscule tolerances. CNC machines use programmed instructions to control the movement of cutting tools with extreme accuracy. This level of control ensures that each part produced adheres closely to the design specifications. In the medical device industry, components like surgical implants also demand high - tolerance precision machining. Implants need to fit perfectly within the human body to function correctly and avoid causing any harm or discomfort to the patient.

Consistent Dimensional Accuracy

Precision machining parts also offer consistent dimensional accuracy. When producing a large batch of parts, traditional machining methods may result in variations in dimensions from one part to another. However, precision machining processes maintain a high level of consistency.

For instance, in a study comparing traditional machining and precision machining for manufacturing automotive engine pistons, traditional machining had a dimensional variance of up to ±0.05 mm in the diameter of the piston. In contrast, precision machining reduced this variance to ±0.01 mm. This high level of consistency in precision - machined parts means that they are more interchangeable. In an assembly line, if one part fails, a precision - machined replacement part can be installed with confidence that it will fit perfectly and function as intended, reducing downtime and maintenance costs.

Moreover, consistent dimensional accuracy is crucial for complex assemblies. In the electronics industry, where components are becoming increasingly miniaturized, every millimeter and even micron matters. Printed circuit boards (PCBs) with precision - machined holes and traces ensure that electronic components can be soldered in the exact positions, enabling proper electrical connections and the overall functionality of the device.

Enhanced Performance and Durability

High - Quality Materials and Processing

Precision machining parts are often crafted from high - quality materials. In the aerospace industry, materials like titanium alloys are commonly used. Titanium alloys offer an excellent strength - to - weight ratio, which is crucial for aircraft components. They can withstand high temperatures and mechanical stresses while keeping the overall weight of the aircraft in check.

The processing of these materials in precision machining is also highly specialized. For Yigu Technology example, in the manufacturing of turbine blades for jet engines, a combination of precision casting and subsequent precision machining operations is carried out. Precision casting helps to get close to the final shape of the blade, reducing the amount of material that needs to be removed during machining. Then, precision milling and grinding processes are used to achieve the exact aerodynamic shape and surface finish required. This not only ensures the high - performance operation of the turbine blade but also contributes to its durability.

Resistance to Wear and Tear

Precision - machined parts exhibit remarkable resistance to wear and tear. Take the example of precision - machined gears in a high - performance automotive transmission. These gears are cut with extreme precision, resulting in smooth tooth profiles. The smooth meshing of these gears reduces friction during operation.

According to a study by a leading automotive research institute, precision - machined gears in a transmission system can reduce friction by up to 30% compared to conventionally - machined gears. This reduction in friction not only improves the efficiency of the transmission but also minimizes the wear on the gear teeth. As a result, the lifespan of the transmission can be extended by 2 - 3 times.

In addition, precision - machined parts can also be treated with special coatings to enhance their resistance to corrosion. For instance, in marine applications, parts made of stainless steel are often precision - machined and then coated with a layer of protective polymer. This coating protects the part from the corrosive effects of saltwater, ensuring that the part can function properly for an extended period, even in harsh marine environments.

Cost - Efficiency in the Long Run

Reduced Waste and Scrap Rates

Precision machining significantly reduces waste and scrap rates, which is a crucial factor in cost - efficiency. Traditional machining methods often result in higher material waste due to less accurate cutting and shaping processes.

For example, in the production of metal components for the automotive industry, traditional machining might have a scrap rate of around 15 - 20%. This means that for every 100 units produced, 15 - 20 units are discarded because they do not meet the required specifications. In contrast, precision machining, with its high - tolerance capabilities, can reduce the scrap rate to as low as 5 - 8%.

The reduced waste not only saves on raw material costs but also on the energy and labor required to process the wasted materials. High - quality precision machining equipment can precisely control the amount of material removed during operations like milling and turning. This ensures that the final product is as close as possible to the desired dimensions right from the start, minimizing the need for excessive material removal and subsequent waste.

Fewer Assembly and Maintenance Issues

Precision - machined parts also contribute to cost - efficiency by reducing assembly and maintenance issues. In the assembly process, parts with high precision fit together more easily and accurately. This reduces the time and labor required for assembly.

A study in the electronics manufacturing industry found that when using precision - machined parts for circuit board components, the assembly time was reduced by 30%. Workers did not need to spend extra time adjusting or reworking parts to make them fit. This increased the overall productivity of the assembly line, as more products could be assembled in the same amount of time.

In terms of maintenance, precision - machined parts have a longer lifespan and require less frequent maintenance. Their consistent quality and high - tolerance dimensions mean that they are less likely to experience premature wear, misalignment, or other mechanical failures. For instance, in industrial machinery, precision - machined bearings can operate smoothly for a much longer time compared to bearings made with less - precise machining methods. This reduces the need for costly maintenance operations, such as bearing replacements, and also minimizes unplanned downtime, which can be extremely expensive for manufacturing companies. Overall, the cost savings from reduced assembly and maintenance issues can have a significant positive impact on the long - term cost - efficiency of manufacturing processes.

Design Flexibility and Complex Geometry Capabilities

Customization for Unique Requirements

Precision machining parts offer unparalleled design flexibility, making them an ideal choice for industries with diverse and unique requirements. In the medical device industry, for example, custom - made implants need to be tailored to fit the specific anatomy of each patient. Precision machining allows manufacturers to create implants with precise shapes and dimensions, ensuring a perfect fit.

A case in point is the production of cranial implants. These implants must match the exact curvature and contour of the patient's skull defect. Through precision machining, medical device companies can use 3D imaging data of the patient's skull to design and manufacture implants with extremely high accuracy. This not only improves the effectiveness of the implant but also reduces the risk of complications during surgery.

In the electronics industry, as devices become smaller and more powerful, the demand for custom - designed precision parts has increased. For instance, high - end smartphones require components such as printed circuit boards (PCBs) with intricate patterns and precise component placements. Precision machining enables the production of PCBs with micro - sized traces and holes, meeting the strict requirements of modern electronics manufacturing. This customization also extends to the production of custom - shaped heat sinks. These heat sinks are designed to fit specific device layouts and provide optimal heat dissipation, which is crucial for maintaining the performance and longevity of electronic components.

Creation of Intricate Geometries

Precision machining techniques have revolutionized the ability to create intricate geometries in manufacturing. Technologies like 3D printing and five - axis machining have opened up new possibilities for producing complex - shaped parts.

3D printing, also known as additive manufacturing, builds parts layer by layer from a digital model. This process allows for the creation of parts with internal cavities, complex lattice structures, and organic shapes that are nearly impossible to achieve with traditional machining methods. In the aerospace industry, 3D printing is used to manufacture lightweight components with complex internal cooling channels. These channels help to regulate the temperature of engine parts, improving their performance and efficiency. For example, GE Aviation uses 3D printing to produce fuel nozzles for its jet engines. The complex internal geometry of these nozzles, which was made possible by 3D printing, allows for better fuel atomization, resulting in more efficient combustion and reduced emissions.

Five - axis machining is another advanced precision machining technology. It enables the simultaneous movement of a workpiece along five axes (X, Y, Z, A, and C), providing greater access to all sides of the workpiece. In the automotive industry, five - axis machining is used to create engine components with complex curved surfaces. For example, the machining of engine cylinder heads requires the creation of intricate ports and combustion chambers. Five - axis machining allows for the precise shaping of these components, optimizing their performance. The ability to machine these complex geometries in a single setup also reduces the need for multiple operations and re - fixturing, improving production efficiency and part accuracy.

Comparison with Other Manufacturing Methods

When considering different manufacturing methods, precision machining parts stand out with their unique characteristics. Here is a comparison table highlighting the differences between precision machining parts, traditional machining, and additive manufacturing in several key aspects:

| Comparison Aspect | Precision Machining Parts | Traditional Machining | Additive Manufacturing |

| Precision Level | High - micron or sub - micron level | Moderate - millimeter level | Varies, generally lower in some aspects |

| Material Waste | Low | High | Varies, often less waste in some cases but high in material usage for support structures |

| Complexity of Geometry | High - can create very complex shapes | Limited - difficult for highly complex geometries | High - good for complex geometries but with some limitations |

| Production Speed for Small Batches | Moderate | Slow | Fast |

| Production Speed for Large Batches | Slow | Fast | Slow |

Precision Level

Precision machining parts offer an incredibly high precision level, often reaching the micron or even sub - micron level. This is crucial for applications like semiconductor manufacturing, where the tiniest deviation can render a product useless. In contrast, traditional machining has a moderate precision level, typically in the millimeter range. Additive manufacturing, while improving in precision, still generally lags behind precision machining in some aspects, especially for high - tolerance applications.

Material Waste

Material waste is a significant factor in manufacturing costs. Precision machining generates low material waste because the machining processes are highly controlled, removing only the necessary amount of material. Traditional machining, on the other hand, often results in high material waste due to the nature of subtractive processes. Additive manufacturing has the potential for less waste as it builds parts layer by layer, adding material only where needed. However, support structures, which are sometimes required for complex geometries, can increase material usage and waste.

Complexity of Geometry

Precision machining parts can achieve a high degree of geometric complexity. Advanced machining techniques, such as multi - axis machining, enable the creation of intricate shapes. Traditional machining faces limitations when it comes to highly complex geometries. Additive manufacturing is well - known for its ability to create complex geometries, but there are still some limitations, such as surface finish and the strength of the final product in certain areas.

Production Speed

For small - batch production, additive manufacturing has a fast production speed as it can quickly create parts directly from a digital model without the need for extensive tooling setup. Precision machining parts have a moderate production speed in small - batch production, while traditional machining is relatively slow due to the need for setting up tools and fixtures for each part. In large - batch production, traditional machining takes the lead with its fast production speed, as the setup time can be spread over a large number of parts. Precision machining is slow in large - batch production due to the high - precision and time - consuming nature of the processes. Additive manufacturing also struggles in large - batch production as the layer - by - layer building process is inherently time - consuming.

Yigu Technology's Viewpoint

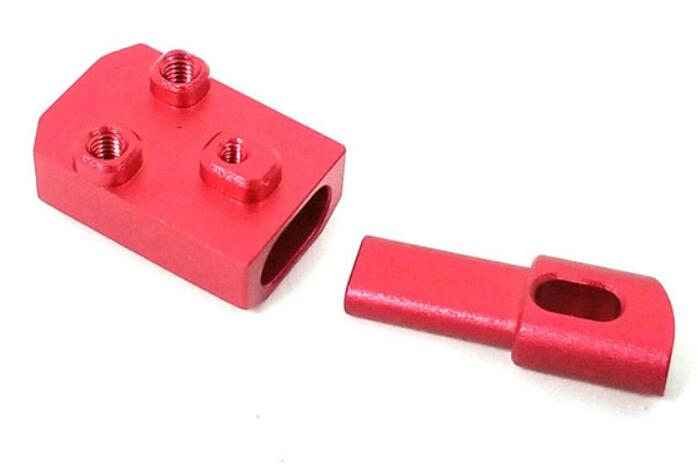

As a non - standard plastic and metal products custom supplier, Yigu Technology deeply understands the significance of precision machining parts in manufacturing. Our long - term experience in custom - made product manufacturing has demonstrated that precision machining parts are the cornerstone for meeting diverse customer needs.

With precision machining technology, we can handle complex design requirements from customers. Whether it's creating unique - shaped plastic components for electronics or high - strength metal parts for industrial equipment, our precision machining capabilities ensure that each part is made to the exact specifications. This not only satisfies the customers' unique needs but also significantly improves the quality of the final products. For example, in one project, a customer required a non - standard plastic part with intricate internal channels. Through precision machining, we were able to achieve the required accuracy, and the final product had excellent performance, which was highly praised by the customer. In short, precision machining parts, with their precision and flexibility, are crucial for us to provide high - quality custom - made products and maintain a competitive edge in the market.