Introduction

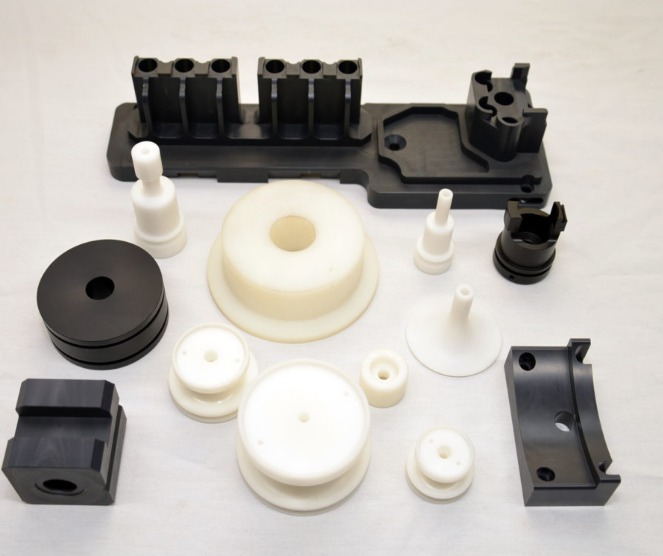

In the ever - evolving landscape of precision manufacturing, CNC plastic parts have emerged as a game - changer. Precision manufacturing demands the highest level of accuracy, repeatability, and quality in the production of components. CNC (Computer Numerical Control) plastic parts are playing an increasingly crucial role in meeting these demands across a wide range of industries.

From the intricate components in medical devices to the lightweight and durable parts in the aerospace industry, CNC plastic parts offer unique advantages. They have become an essential part of modern manufacturing processes, enabling the creation of products that were once considered too complex or costly to produce. This article will explore how CNC plastic parts are revolutionizing precision manufacturing, from their design flexibility and high - precision capabilities to their cost - effectiveness and material versatility.

Understanding CNC Plastic Parts

Definition and Basics

CNC plastic parts are components produced through the Computer Numerical Control machining process, using plastic materials. In CNC machining, pre-programmed computer software dictates the movement of factory tools and machinery. This technology allows for the creation of highly precise plastic parts by removing material from a solid plastic block or sheet. The process starts with a digital 3D model of the part. This model is then converted into a set of instructions, known as G - code, which the CNC machine reads to control the movement of the cutting tools, such as mills, lathes, or routers. For example, a small, intricate plastic gear used in a precision - driven device can be crafted with extreme accuracy using CNC machining. The machine can precisely carve the teeth of the gear, ensuring that the pitch and diameter are within tight tolerances, typically as low as ±0.001 inches in high - precision applications.

Materials Used

- Acrylonitrile Butadiene Styrene (ABS)

- Characteristics: ABS is a popular thermoplastic known for its strength, impact resistance, and good dimensional stability. It has a relatively low melting point, which makes it easy to process. ABS also offers excellent surface finish capabilities, and it can be easily painted, plated, or textured.

- Applicable Scenarios: In the automotive industry, ABS is used for interior components like dashboards and door panels due to its aesthetic appeal and durability. It is also commonly used in consumer electronics, such as the outer casing of keyboards and small appliances, because of its ability to withstand everyday wear and tear.

- Polycarbonate (PC)

- Characteristics: PC is a high - performance plastic with outstanding impact strength, even at low temperatures. It has excellent optical properties, being highly transparent, and also offers good heat resistance. PC is known for its dimensional stability over a wide range of temperatures and its resistance to many chemicals.

- Applicable Scenarios: In the aerospace industry, PC is used for making aircraft windows and canopies due to its high - strength - to - weight ratio and optical clarity. In the medical field, it is used in the production of surgical instruments and medical device components that require sterilization, as PC can withstand the heat and chemical sterilization processes.

- Polyethylene (PE)

- Characteristics: PE is a lightweight, flexible, and chemically resistant plastic. It comes in different densities, such as High - Density Polyethylene (HDPE) and Low - Density Polyethylene (LDPE). HDPE offers high strength and stiffness, while LDPE is more flexible and has better impact resistance at low temperatures. PE is also non - toxic and has good electrical insulating properties.

- Applicable Scenarios: LDPE is often used for making plastic bags, films, and flexible packaging materials because of its flexibility and low cost. HDPE is used in applications like pipes for water and gas distribution, as well as in the production of plastic containers for storing chemicals and consumer products, due to its strength and chemical resistance.

Advantages of CNC Plastic Parts in Precision Manufacturing

High Precision

CNC plastic parts are renowned for their high precision. The CNC machining process can achieve tolerances as tight as ±0.025 - 0.125mm in many cases. For instance, in the production of medical device components like micro - fluidic channels, where precise fluid flow control is crucial, CNC - machined plastic parts can maintain consistent channel dimensions within these tight tolerances. In contrast, traditional manufacturing methods such as manual machining or simple casting often have much larger tolerances. Manual machining might have tolerances in the range of ±0.5 - 1mm, which is far too imprecise for applications that require high - precision plastic parts. This high precision of CNC plastic parts ensures that components fit together perfectly, reducing the need for additional fitting or adjustment during assembly, and ultimately improving the overall performance of the final product.

Consistency in Production

CNC machining ensures remarkable consistency in the production of plastic parts. Once the program is set, the CNC machine will execute the same operations repeatedly with high accuracy. Consider a scenario where a company needs to produce 1000 identical plastic brackets for an electronic device. With CNC machining, each bracket will have the exact same dimensions, surface finish, and quality characteristics.

The following table shows the consistency comparison between different production methods:

| Production Method | Variation in Dimensions (for a part with a nominal size of 50mm) | Quality Consistency |

| CNC Machining | ±0.05mm | High - consistent quality, little variation between parts |

| Manual Machining | ±0.5mm | High variability, quality depends on operator skill |

| Traditional Casting | ±0.3mm | Medium variability, affected by casting process variables |

This consistency is vital for industries such as automotive and aerospace, where parts must meet strict quality and interchangeability standards.

Design Flexibility

CNC plastic parts offer unparalleled design flexibility. Complex geometries that would be extremely difficult or even impossible to achieve with traditional manufacturing methods can be easily created using CNC machining. For example, parts with internal cavities, intricate undercuts, and complex surface textures can be produced with precision. In the design of a custom - made plastic housing for a high - end camera, the housing may require a unique shape to fit specific components and ergonomic requirements. CNC machining can bring this design to life, allowing for the creation of curved surfaces, precise cut - outs for buttons and lenses, and internal ribs for structural support. This design flexibility enables product designers to push the boundaries of innovation, creating products that are not only functional but also aesthetically pleasing and unique.

Cost - effectiveness in the Long Run

Although the initial investment in CNC machinery and programming can be high, CNC plastic parts are cost - effective in the long run. Firstly, CNC machining reduces material waste. Since the process is highly precise, it can cut and shape plastic materials with minimal excess, unlike traditional methods that may result in a significant amount of scrap material. For example, when manufacturing large plastic panels with complex shapes, CNC cutting can optimize the layout of the parts on the raw material sheet, reducing waste by up to 30% compared to traditional cutting methods.

Secondly, the high - precision and consistency of CNC - produced parts mean that there are fewer rejects during the production process. Fewer rejects translate to lower costs associated with rework or replacement. In addition, the automation of the CNC process reduces the need for a large number of skilled operators, cutting down on labor costs over time. For long - term production runs, these factors combined can lead to substantial cost savings, making CNC plastic parts an economically viable option for precision manufacturing.

Applications of CNC Plastic Parts in Various Industries

Aerospace

In the aerospace industry, every component must meet the most stringent requirements in terms of weight, strength, and reliability. CNC plastic parts have found their niche in this high - stakes industry due to several key characteristics. Their lightweight nature is a significant advantage. For example, in aircraft interiors, CNC - machined plastic parts such as seat components, overhead bin panels, and interior trim pieces can reduce the overall weight of the aircraft. A reduction in weight leads to lower fuel consumption, which in turn decreases operating costs and increases the aircraft's range. According to industry data, a 10% reduction in aircraft weight can lead to a 6 - 8% reduction in fuel consumption.

Moreover, plastic materials used in CNC machining can offer excellent corrosion resistance, which is crucial in the harsh aerospace environment, where components are exposed to various chemicals, moisture, and extreme temperatures. Some high - performance plastics also have good heat - resistant properties, allowing them to be used in engine - related components, such as non - structural engine cowling parts. The high precision of CNC plastic parts ensures that they fit perfectly within the complex aerospace assemblies, contributing to the overall integrity and safety of the aircraft or spacecraft.

Medical

In medical device manufacturing, CNC plastic parts play a vital role. The medical industry demands components with extremely tight tolerances, high biocompatibility, and the ability to be sterilized. CNC - machined plastic parts can meet these requirements. For instance, in the production of surgical instruments, CNC - made plastic handles provide a comfortable and ergonomic grip for surgeons. These plastic handles are often made from biocompatible plastics like Polyether - ether - ketone (PEEK), which is not only biocompatible but also has high strength and can withstand repeated sterilization processes, whether it's through autoclaving (exposure to high - pressure steam) or chemical sterilization methods.

In the field of medical implants, CNC - produced plastic components are being increasingly used. For example, some custom - made orthopedic implants use plastic parts in combination with metal components. These plastic parts can be designed to mimic the natural flexibility and elasticity of human tissues, providing better comfort and functionality for patients. Additionally, in diagnostic equipment such as micro - fluidic devices for blood analysis, CNC - machined plastic channels and chambers ensure precise fluid flow and sample handling, contributing to accurate test results.

Electronics

The electronics industry has been greatly influenced by CNC plastic parts. As electronic devices continue to miniaturize and become more complex, the need for precise and small - scale components has grown. CNC plastic parts are used in a variety of electronic devices. In smartphones, for example, the internal plastic frames and brackets that hold the circuit boards, batteries, and other components are often CNC - machined. These parts are designed with high precision to ensure a perfect fit, protecting the delicate electronic components from damage and ensuring proper functionality.

In high - end audio equipment, CNC - made plastic speaker enclosures can be designed to have specific acoustic properties. The precise shaping of the enclosure using CNC machining helps to optimize sound quality by reducing unwanted resonances and improving sound dispersion. In addition, plastic parts used in the manufacturing of electronic connectors are made with high precision using CNC technology. These connectors need to have consistent dimensions to ensure reliable electrical connections, and CNC - produced plastic parts can meet these requirements, contributing to the overall performance and reliability of electronic devices.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology firmly believes that CNC plastic parts hold a bright future in precision manufacturing. The high precision and design flexibility of CNC plastic parts perfectly align with our custom - manufacturing services. We can take on projects with complex design requirements, leveraging the capabilities of CNC machining to bring unique plastic part designs to life.

Our in - house expertise allows us to work with a wide range of plastic materials, ensuring that each part meets the specific performance requirements of our clients. By offering custom CNC plastic parts, we can help businesses reduce costs associated with off - the - shelf components that may not fit their needs precisely. Moreover, we are committed to continuous improvement in our CNC manufacturing processes, staying updated with the latest technology to provide even higher - quality parts. We see CNC plastic parts as a driving force for innovation in precision manufacturing, and we are excited to be a part of this dynamic industry, contributing to the growth and success of our clients through our high - quality custom solutions.

FAQ

Q1: What is the typical turnaround time for CNC plastic parts production?

A: The turnaround time depends on factors like part complexity, quantity, and material availability. For simple parts in small quantities, it can be as short as 3 - 5 business days. Complex parts or large - scale production may take 1 - 2 weeks or more.

Q2: Can CNC plastic parts be used in high - temperature applications?

A: Some plastic materials used in CNC machining, such as PEEK (Polyether - ether - ketone) and certain grades of polycarbonate, have good heat - resistant properties. PEEK can withstand temperatures up to around 260°C continuously, making it suitable for some high - temperature applications in industries like aerospace and automotive engine - related components.

Q3: How do I ensure the quality of CNC plastic parts?

A: Reputable manufacturers use quality control measures like in - process inspections, post - production dimensional checks using precision measuring equipment (such as coordinate measuring machines - CMMs), and material testing to verify the properties of the plastic material used. Also, look for manufacturers with quality management systems, such as ISO 9001 certification, which ensures a standardized and reliable production process.

Conclusion

CNC plastic parts have truly revolutionized precision manufacturing. Their high precision, consistency in production, design flexibility, and long - term cost - effectiveness make them an ideal choice for a wide range of industries. From the aerospace industry's need for lightweight and reliable components to the medical field's demand for biocompatible and precise parts, and the electronics industry's pursuit of miniaturization and high - performance components, CNC plastic parts have proven their worth.

In conclusion, CNC plastic parts will continue to play a pivotal role in the future of precision manufacturing, driving innovation and enabling the creation of more advanced and high - quality products across various industries.