Introduction

Definition and Function of Hot Runner Systems

Hot Runner Systems, also known as hot manifold systems, are heating component systems used in injection molds. Their primary function is to inject molten plastic particles into the mold cavity. By maintaining the plastic in the runner and gate in a molten state, they ensure a smooth and continuous flow of plastic during the injection molding process. This is achieved through the use of heating elements such as heaters and heating coils, which keep the entire runner system, from the injection machine nozzle outlet to the gate, at a high temperature. As a result, the plastic in the runner remains molten, eliminating the need to remove solidified runner material after each molding cycle. When starting the machine again, only the runner needs to be heated to the required temperature, which greatly simplifies the process and improves production efficiency.

Given the importance of hot runner systems in plastic injection molding, understanding their different types and components is essential for manufacturers, mold designers, and engineers. It allows them to make informed decisions when choosing the right hot runner system for their specific applications, ensuring optimal performance, cost - effectiveness, and product quality.

Types of Hot Runner Systems

Adiabatic Hot Runner Systems

Adiabatic hot runner systems are designed to maintain the heat within the runner system with minimal heat loss. In this system, the runner is surrounded by a thick layer of insulating material, and heating elements such as heating rods and heating coils are used to keep the plastic in the runner at a high temperature. This ensures that the plastic remains in a molten state throughout the injection molding process.

Design and Working Principle

The design of an adiabatic hot runner system is relatively complex. It typically consists of a heated manifold, nozzles, and a temperature control system. The heated manifold distributes the molten plastic to the individual nozzles, which then inject the plastic into the mold cavities. The temperature control system is crucial for maintaining the optimal temperature in the runner system. It monitors and adjusts the heat input from the heating elements to ensure that the plastic viscosity remains consistent. For example, the heating rods are usually placed in a specific pattern within the manifold to provide uniform heating. In some advanced adiabatic hot runner systems, there are multiple temperature zones, allowing for precise control of the temperature at different points in the runner.

Advantages and Disadvantages

- Advantages: One of the significant advantages of adiabatic hot runner systems is their low maintenance cost. Since the runner system is designed to retain heat efficiently, there is less wear and tear on the components due to thermal cycling. Additionally, they are suitable for large - scale production runs as they can handle high - volume plastic injection. For instance, in the automotive industry, when manufacturing large plastic parts like bumpers or interior panels, adiabatic hot runner systems can ensure a continuous and smooth supply of molten plastic, reducing production time and costs associated with frequent mold changes.

- Disadvantages: However, adiabatic hot runner systems also have some limitations. They are not very flexible in terms of handling different plastic materials. Some plastics with specific melting points and flow characteristics may not be suitable for this type of system. Moreover, the initial investment cost for an adiabatic hot runner system is relatively high due to its complex design and the need for high - quality insulating materials and heating components.

Micro Semi - Hot Runner Systems

Micro semi - hot runner systems offer a more simplified approach compared to adiabatic hot runner systems. These systems are designed to be more user - friendly and cost - effective, especially for applications that require high precision.

Design and Working Principle

In a micro semi - hot runner system, the runner is only partially heated. The system typically consists of a small - diameter runner that is heated to keep the plastic in a molten state near the mold cavities. The heating elements are usually located close to the nozzles, which helps in reducing heat loss and ensuring quick response times. For example, in a precision mold for producing small electronic components, the micro semi - hot runner system can precisely control the amount of molten plastic reaching each cavity. The small - diameter runner allows for better control over the flow rate and pressure of the plastic, resulting in more consistent part quality.

Advantages and Disadvantages

- Advantages: Micro semi - hot runner systems are known for their high stability and low failure rate. Their simple structure makes them easier to maintain compared to more complex hot runner systems. They are also more energy - efficient as they only heat the necessary parts of the runner. For example, in the production of medical devices, where precision and reliability are crucial, micro semi - hot runner systems can ensure that each part is produced with the highest quality standards, minimizing the risk of defects.

- Disadvantages: The main drawback of micro semi - hot runner systems is that they may not be suitable for large - scale or high - volume production as their capacity is relatively limited compared to adiabatic hot runner systems. They are also more sensitive to changes in the injection molding process parameters, such as injection pressure and temperature.

Tabular Comparison of Different Types

| Comparison Aspect | Adiabatic Hot Runner Systems | Micro Semi - Hot Runner Systems |

| Structure Complexity | High, with a complex design involving thick insulation and precise heating element placement | Low, featuring a simple and straightforward design with partial heating |

| Maintenance Cost | Low due to less thermal cycling and wear on components | Low because of the simple structure and fewer components to maintain |

| Applicable Product Types | Ideal for large - scale production of large plastic parts, such as automotive components | Suitable for high - precision production of small parts, like electronic components or medical devices |

| Initial Cost | High, mainly due to the need for high - quality insulating materials and complex heating systems | Relatively low, as the design is less complex and requires fewer components |

| Production Stability | High stability for high - volume production | High stability for precision production, but may be affected more by process parameter changes |

Components of Hot Runner Systems

Hot Runner Nozzles

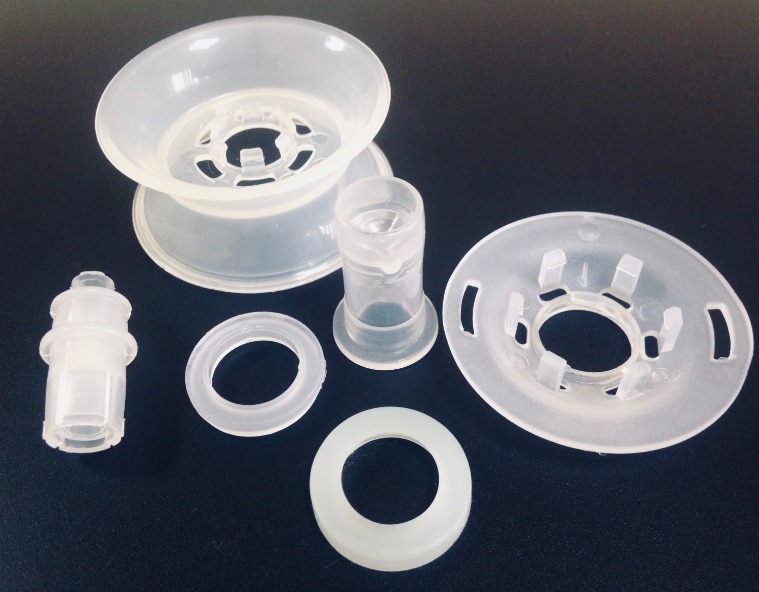

Open Nozzles

Open nozzles are the simplest type of hot runner nozzles. They are commonly used in micro semi - hot runner systems. These nozzles have a straightforward structure with an open tip that directly contacts the small - diameter runner in the mold. Their design allows for a relatively low - cost solution, making them suitable for applications where cost - effectiveness is a key factor. For example, in the production of small plastic parts with simple shapes and low - volume requirements, open nozzles can be a practical choice.

However, open nozzles also have some limitations. One of the main issues is the potential for stringing or drooling. When the injection cycle ends and the plastic flow stops, a small amount of plastic may continue to flow out of the open nozzle, creating thin strands or drooping material. This can affect the appearance and quality of the molded parts, especially in applications where a clean and smooth surface finish is required. To mitigate this problem, it is important to carefully control the injection pressure and temperature, and to ensure that the nozzle tip is properly designed and maintained. Regular cleaning and inspection of the nozzles can also help to prevent the build - up of plastic residue that can contribute to stringing.

Needle Valve Nozzles

Needle valve nozzles offer several advantages over open nozzles. These nozzles are equipped with a movable needle that can be precisely controlled to open and close the flow of plastic. When the needle is closed, it effectively seals the nozzle, preventing any plastic from leaking out. This feature is particularly useful in applications where preventing flash, stringing, and drooling is crucial.

There are two main types of needle valve nozzles: cylinder - actuated and spring - actuated.

- Cylinder - actuated needle valve nozzles: These nozzles use a hydraulic or pneumatic cylinder to move the needle. The cylinder provides a strong and precise force, allowing for accurate control of the needle position. Cylinder - actuated nozzles are often preferred for high - volume production and applications that require tight control over the injection process. For example, in the automotive industry, when manufacturing large plastic parts with complex shapes and high - quality requirements, cylinder - actuated needle valve nozzles can ensure consistent and accurate filling of the mold cavities.

- Spring - actuated needle valve nozzles: Spring - actuated nozzles, on the other hand, use a spring to close the needle. When the injection pressure overcomes the spring force, the needle opens, allowing the plastic to flow. Spring - actuated nozzles are generally more cost - effective and simpler in design compared to cylinder - actuated nozzles. They are suitable for applications where the injection pressure is relatively stable and the need for extremely precise control is not as critical. For instance, in the production of small consumer goods such as plastic toys or household items, spring - actuated needle valve nozzles can provide a reliable and cost - efficient solution.

The main advantage of needle valve nozzles is the ability to eliminate or significantly reduce the appearance of gate vestiges on the molded parts. Since the needle can be precisely timed to open and close, it allows for better control over the filling and packing of the mold cavities. This results in parts with a cleaner surface finish, fewer defects, and improved dimensional accuracy. Additionally, needle valve nozzles can help to reduce material waste by minimizing the amount of plastic that is left in the runner system after each injection cycle.

Hot Runner Manifolds

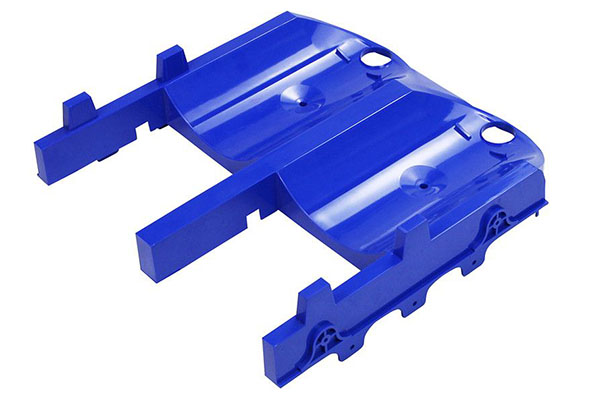

The hot runner manifold is a crucial component of the hot runner system. Its primary function is to distribute the molten plastic from the injection machine nozzle to the individual hot runner nozzles. The design and manufacturing precision of the manifold play a vital role in ensuring an even distribution of plastic and consistent injection quality across all cavities.

In terms of design, the manifold must be carefully engineered to minimize pressure drops and ensure that the plastic flows evenly to each nozzle. This often involves optimizing the layout of the internal channels, which can be designed in various configurations such as linear, branched, or circular, depending on the specific requirements of the mold and the number of cavities. For example, in a multi - cavity mold with a large number of evenly spaced cavities, a linear or branched manifold design may be more suitable to ensure equal flow to each cavity.

The manufacturing process of the manifold requires high - precision machining techniques. The internal channels need to be machined with tight tolerances to ensure smooth plastic flow and prevent any leakage. Additionally, the manifold is usually made of high - quality materials such as tool steel or stainless steel, which can withstand the high temperatures and pressures involved in the injection molding process. Heat treatment may also be applied to improve the material's mechanical properties and durability.

A well - designed and manufactured hot runner manifold can improve the efficiency and quality of the injection molding process. It helps to reduce cycle times by ensuring a faster and more uniform filling of the mold cavities. Moreover, it can enhance the consistency of the molded parts, reducing variations in size, weight, and quality.

Heating Elements

Heating elements are essential for maintaining the high temperature required to keep the plastic in the hot runner system in a molten state. The two most common types of heating elements used in hot runner systems are heating rods and heating coils.

Heating rods are typically made of materials with high electrical resistance, such as nichrome. When an electric current passes through the heating rod, the resistance generates heat, which is then transferred to the surrounding components, including the hot runner manifold and nozzles. Heating coils, on the other hand, are usually made of a coiled wire and are often wrapped around the hot runner components. They work on the same principle of resistive heating, but their coiled shape allows for more flexible installation and better heat distribution in some cases.

The power of the heating elements needs to be carefully selected based on several factors. These include the size of the hot runner system, the type of plastic being processed, and the desired operating temperature. For example, larger hot runner systems or plastics with higher melting points will generally require more powerful heating elements to ensure that the plastic remains molten throughout the injection cycle. If the heating power is too low, the plastic may solidify in the runner system, leading to blockages and production disruptions. Conversely, if the heating power is too high, it can cause overheating, which may degrade the plastic material and affect the quality of the molded parts.

When choosing heating elements, it is also important to consider their durability and reliability. High - quality heating elements are designed to withstand the harsh operating conditions of the hot runner system, including high temperatures and frequent thermal cycling. They should have a long service life and be resistant to oxidation and corrosion. Additionally, proper installation and maintenance of the heating elements are crucial to ensure their optimal performance. This includes ensuring good electrical connections, regular inspection for signs of wear or damage, and timely replacement of any faulty components.

Temperature Controllers

Temperature controllers are used to precisely regulate the temperature of the hot runner system. They play a critical role in maintaining the stability and performance of the system, as the temperature of the hot runner has a direct impact on the quality of the molded parts.

There are several types of temperature controllers commonly used in hot runner systems, with the most common being proportional - integral - derivative (PID) controllers. PID controllers work by continuously monitoring the actual temperature of the hot runner system using temperature sensors, such as thermocouples or resistance temperature detectors (RTDs). The controller then compares the measured temperature with the set - point temperature and calculates the appropriate control signal to adjust the power supplied to the heating elements.

For example, if the measured temperature is lower than the set - point, the PID controller will increase the power to the heating elements to raise the temperature. Conversely, if the measured temperature is higher than the set - point, the controller will reduce the power to prevent overheating. The integral and derivative terms in the PID algorithm help to eliminate any steady - state error and improve the response time of the controller, respectively.

To ensure accurate temperature control, it is important to select a temperature controller that is compatible with the hot runner system and the type of temperature sensors being used. The controller should have a high - resolution display and easy - to - use interface for setting and adjusting the temperature parameters. Regular calibration of the temperature sensors and the controller is also essential to maintain accurate temperature measurement and control. Additionally, proper installation and shielding of the temperature sensors are necessary to prevent interference from external factors, such as electromagnetic fields or mechanical vibrations, which can affect the accuracy of the temperature readings.

Choosing the Right Hot Runner Supplier

Reputation and Experience

When selecting a hot runner supplier, reputation and experience are of utmost importance. A supplier with a good reputation has likely built it over time by consistently delivering high - quality products and excellent service. For example, YUDO, a well - known hot runner supplier, has been in the industry for decades. It has a wide range of successful applications in various industries, especially in the Asian market where it holds a significant market share. Their long - standing presence indicates their in - depth understanding of different customer needs and their ability to adapt to changing market demands.

Milacron is another renowned name in the hot runner industry. With a global footprint, they have been involved in numerous large - scale projects across different sectors such as automotive, electronics, and packaging. Their experience allows them to offer comprehensive solutions, from the initial design stage to the after - sales service. They have a vast knowledge base on different types of plastics, injection molding processes, and hot runner system requirements, which enables them to provide accurate and reliable advice to their customers.

Product Quality and Reliability

Product quality and reliability are the cornerstones of a successful hot runner system. High - quality hot runner components are essential for minimizing system failures and maximizing production efficiency. A reliable hot runner system can reduce costly downtime, improve product quality, and enhance overall productivity. For instance, if a hot runner nozzle fails during production, it can lead to a halt in the injection molding process, resulting in lost production time, wasted materials, and potential damage to the mold.

To ensure product quality, look for suppliers that use high - grade materials in their components. High - quality heating elements, for example, are made of materials with excellent heat - conducting properties and high resistance to oxidation and wear. Stainless steel is commonly used for hot runner manifolds and nozzles due to its durability and ability to withstand high temperatures and pressures. Additionally, suppliers should have strict quality control processes in place, such as thorough inspections, testing, and certifications. ISO 9001 certification, for example, is a widely recognized standard that indicates a company's commitment to quality management.

Technical Support and After - Sales Service

Technical support and after - sales service are crucial aspects to consider when choosing a hot runner supplier. A good supplier should be able to provide comprehensive technical support throughout the entire life cycle of the hot runner system. This includes assistance with system design, installation, troubleshooting, and maintenance.

During the installation phase, the supplier's technical team should be available to provide on - site guidance to ensure that the hot runner system is correctly installed. In case of any issues, they should be able to respond promptly and provide effective solutions. For example, if there are temperature control problems in the hot runner system, the supplier should be able to diagnose the issue quickly, whether it is a problem with the temperature controller, the heating elements, or the wiring, and offer appropriate remedies.

After - sales service also includes the availability of spare parts. A reliable supplier should have a good inventory of spare parts, ensuring that any damaged or worn - out components can be replaced promptly. This reduces the downtime of the production line and keeps the injection molding process running smoothly. Additionally, some suppliers offer training programs to help customers' employees better understand the operation and maintenance of the hot runner system, which can significantly improve the system's performance and lifespan.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology recognizes the pivotal role that hot runner systems play in the injection molding industry. The ability of hot runner systems to enhance product quality, reduce material waste, and shorten cycle times aligns with our commitment to providing high - quality customized solutions.

Although the mold structure with hot runner systems is complex and the cost is relatively high, the long - term benefits, such as material savings and improved production efficiency, are significant. We are eager to collaborate with reliable hot runner suppliers. By working together, we can integrate hot runner systems into our customized product designs, offering our customers a more comprehensive and optimized solution. This cooperation will not only improve the performance of our products but also enhance our competitiveness in the market, ultimately bringing more value to our clients.

FAQ

Q1: How do I choose the right type of hot runner system for my application?

A: Consider factors like the type of plastic, product size, production volume, and quality requirements. For large - scale production of large parts, adiabatic hot runner systems may be suitable. For high - precision small - part production, micro semi - hot runner systems could be a better choice.

Q2: What are the common problems with hot runner nozzles and how to solve them?

A: Open nozzles may experience stringing or drooling. To solve this, carefully control injection pressure and temperature, and regularly clean and maintain the nozzle tip. Needle valve nozzles may have issues with the needle movement. Ensure proper installation and regular inspection of the actuating mechanism (cylinder - actuated or spring - actuated).

Q3: How important is the reputation of a hot runner supplier?

A: A supplier's reputation is very important. A good - reputation supplier, like YUDO or Milacron, has likely been in the industry for a long time, has a wealth of experience, and can provide high - quality products and reliable after - sales service. They are more likely to understand your needs and offer effective solutions.