Factors Influencing the Cost of Mold Plastic Parts

Material Selection

Types of Plastics and Their Cost Variations

Plastic materials play a fundamental role in determining the cost of mold plastic parts. Different types of plastics have distinct price points. For instance, ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic with good mechanical properties, heat resistance, and surface finish. It is often used in applications such as automotive interior parts, electronics housings, and toys. The price of ABS can range from \(1.5 - \)3 per kilogram, depending on factors like brand, quality, and market conditions.

PP (Polypropylene) is another widely - used plastic known for its low density, chemical resistance, and good heat resistance. It is commonly found in products like food containers, packaging materials, and automotive bumpers. PP is generally more cost - effective than ABS, with a price range of approximately \(1 - \)2 per kilogram. This makes it a preferred choice for applications where cost - savings are a priority without sacrificing too much on performance.

PE (Polyethylene) comes in different grades, such as HDPE (High - Density Polyethylene) and LDPE (Low - Density Polyethylene). HDPE, which is rigid and has high strength, is used in applications like pipes, buckets, and industrial containers. LDPE, on the other hand, is more flexible and is often used in plastic bags and film applications. The cost of PE also varies by grade, with HDPE typically priced around \(1 - \)1.5 per kilogram and LDPE slightly lower, at around \(0.9 - \)1.3 per kilogram. These cost differences directly impact the overall cost of mold plastic parts, especially when large quantities of materials are required.

Impact of Material Quality on Cost

High - quality materials usually come with a higher price tag, but they can have a significant impact on the overall cost in the long run. For example, high - purity plastics with consistent molecular structures are less likely to cause issues during the molding process, such as uneven melting, flow problems, or inconsistent cooling. This can lead to a lower reject rate of parts.

Let's assume a manufacturing scenario where a lower - quality plastic is used, and the reject rate during production is 10%. If the cost of the raw material is \(1 per kilogram and 100 kilograms of material are used to produce 1000 parts, but 100 parts are rejected, the effective cost per acceptable part for materials is higher. In contrast, if a high - quality material costing \)1.2 per kilogram is used, and the reject rate drops to 2%, the overall cost per acceptable part may be lower or at least more stable, considering the reduced waste and re - production costs.

Mold Design Complexity

Geometric Complexity

The geometric complexity of a mold design has a direct bearing on its cost. Consider a simple cube - shaped mold for a plastic part. The design and manufacturing of such a mold are relatively straightforward. The machining operations, such as milling and drilling, are simple and require less time.

However, when we look at a mold with complex geometric shapes, like a mold for a detailed automotive dashboard component with intricate curves, undercuts, and thin - walled sections, the situation changes drastically.

The design process for a complex mold requires more advanced software and highly skilled designers who can spend a significant amount of time ensuring that all the geometric details are accurately translated into a workable design. During manufacturing, complex molds often need multi - axis machining, which is more expensive than traditional machining. Operations like electrical discharge machining (EDM) may be required to create fine details or undercuts, further increasing the manufacturing time and cost.

Number of Cavities

Molds can be designed with a single cavity or multiple cavities. A single - cavity mold is the simplest and least expensive to design and manufacture. It is suitable for low - volume production or when the part is large and complex, making it difficult to fit multiple parts in a single mold.

For high - volume production, multi - cavity molds are often used. While they can increase production efficiency by producing multiple parts in a single cycle, they also come with higher costs. The design of a multi - cavity mold must ensure that each cavity is identical in terms of size, shape, and the flow of the plastic material. This requires precise engineering and tight tolerances.

The manufacturing of a multi - cavity mold is more challenging as well. The mold maker has to ensure that all the cavities are accurately machined and that the gating system, which distributes the molten plastic to each cavity, is designed correctly. If there are any discrepancies in the cavities or the gating system, it can lead to uneven filling of the cavities, resulting in defective parts. For example, a four - cavity mold may cost 2 - 3 times more than a single - cavity mold of similar overall size and complexity, depending on the specific design requirements.

Production Volume

Economies of Scale

The concept of economies of scale is highly relevant when it comes to the cost of mold plastic parts. As the production volume increases, the unit cost of each part decreases. This is because the fixed costs, such as the cost of the mold, equipment setup, and initial design, are spread over a larger number of parts.

Let's take an example. Suppose the cost of a mold is \(10,000, and the variable cost per part (including materials, labor, and energy) is \)2. If 1000 parts are produced, the total cost is \(10,000 (mold cost) + \)2 x 1000 (variable cost) = \(12,000, and the unit cost is \)12. However, if 10,000 parts are produced, the total cost is \(10,000 + \)2 x 10,000 = \(30,000, and the unit cost drops to \)3.

Small - Batch Production Challenges

Small - batch production, on the other hand, faces several cost - related challenges. Since the fixed costs, especially the mold cost, are not spread over a large number of parts, the unit cost remains high. For example, if a small - batch production run of only 100 parts is planned, and the mold cost is still \(10,000 with a variable cost of \)2 per part, the total cost is \(10,000+ \)2 x 100 = \(10,200, and the unit cost is a staggering \)102.

Moreover, in small - batch production, the setup time for the manufacturing equipment may represent a significant portion of the total production time. This is because the equipment has to be adjusted and calibrated for each new production run, even if it's a small one. Additionally, suppliers may charge higher prices for small - quantity material purchases, further contributing to the high unit cost in small - batch production.

Manufacturing Process

Injection Molding

Injection molding is one of the most common manufacturing processes for mold plastic parts. The cost of injection molding can be broken down into several components.

Equipment Costs: Injection molding machines come in different sizes and capabilities, and their cost can range from a few thousand dollars for small, desktop - sized machines to hundreds of thousands of dollars for large, high - capacity industrial machines. Larger machines with higher clamping forces and injection volumes are needed for producing larger or more complex parts.

Mold Costs: As mentioned earlier, the mold is a significant cost factor. The cost of an injection mold depends on its complexity, size, and the materials used in its construction. A simple injection mold for a small, basic part may cost a few thousand dollars, while a complex, multi - cavity mold for a high - precision automotive component can cost hundreds of thousands of dollars.

Labor Costs: Skilled operators are required to set up and run the injection molding machines. They need to monitor the process, adjust parameters such as temperature, pressure, and injection speed, and ensure that the parts are being produced correctly. Labor costs can vary depending on the region and the level of skill required.

Material Costs: The cost of the plastic raw materials, as discussed in the material selection section, is also a major part of the injection molding cost. Additionally, there may be costs associated with additives, colorants, and any pre - processing of the materials.

Compared to other processes, injection molding offers cost - advantages for high - volume production. It has a relatively high production rate, which means that the fixed costs can be spread over a large number of parts quickly. Also, it can produce parts with high precision and complex geometries with minimal post - processing in many cases.

Other Processes (Blow Molding, Rotational Molding)

Blow Molding: This process is mainly used for producing hollow plastic parts, such as bottles, containers, and tanks. The equipment cost for blow molding is generally lower than that of large - scale injection molding machines. However, the molds for blow molding can still be costly, especially for complex - shaped products. The process is cost - effective for high - volume production of hollow parts. For example, the production of plastic water bottles in large quantities using blow molding can achieve economies of scale. But for small - batch production, the cost per unit may be high due to the relatively high mold cost and setup time.

Rotational Molding: Rotational molding is suitable for producing large, hollow, and complex - shaped parts with uniform wall thickness, such as playground equipment, large storage tanks, and some automotive components. The equipment and mold costs for rotational molding are often lower than those of injection molding for large - scale production of such parts. However, the production cycle time in rotational molding is usually longer, which can be a drawback for high - volume production. But for low - to - medium volume production of large parts, rotational molding can be a cost - effective option as it can produce parts without the need for complex tooling and high - pressure equipment.

Post - Processing Operations

Assembly and Finishing

Assembly and finishing operations can significantly increase the cost of mold plastic parts. For example, if a plastic product consists of multiple components, the labor cost associated with assembling these parts can add up. Each part may need to be precisely aligned and joined together, which requires time and skill.

Surface finishing operations, such as painting, polishing, or plating, also contribute to the cost. Painting a plastic part not only requires the cost of the paint and the painting equipment but also skilled labor to ensure an even and high - quality finish. Polishing can be time - consuming, especially if a high - gloss finish is required, and plating involves complex chemical processes and specialized equipment, all of which add to the overall cost.

Quality Control and Inspection

Quality control and inspection are essential for ensuring the quality of mold plastic parts, but they also come at a cost. Employing quality control personnel, using inspection equipment such as coordinate measuring machines (CMMs) for dimensional accuracy checks, and conducting various tests like tensile strength tests, impact resistance tests, and chemical composition analysis all add to the cost.

However, these costs are crucial for maintaining product quality and the company's reputation. A high - quality product with minimal defects can lead to customer satisfaction, repeat business, and a positive brand image. On the other hand, overlooking quality control can result in costly recalls, customer complaints, and damage to the company's reputation, which can have far - reaching financial implications.

Cost - Saving Strategies for Mold Plastic Parts Companies

Design Optimization

Design for Manufacturability (DFM)

Adopting Design for Manufacturability (DFM) principles is crucial for mold plastic parts companies aiming to reduce costs. DFM focuses on simplifying the design of parts to make the manufacturing process more straightforward. For example, reducing the number of undercuts in a mold design can significantly lower the complexity of the mold - making process. Undercuts often require additional machining operations, such as side - actions in injection molding, which increase both the cost of the mold and the production time.

Another aspect of DFM is minimizing unnecessary features. A part with intricate details that do not contribute significantly to its functionality will not only increase the cost of mold design and manufacturing but also the production cost. By streamlining the design, companies can reduce the time required for mold machining, which in turn reduces labor costs and the cost of tooling. This approach can lead to a more efficient production process with fewer production - related issues, ultimately resulting in cost savings.

Standardization

Standardization is another powerful cost - saving strategy in the design phase. Using standard parts and design elements whenever possible can reduce the need for custom - designed molds. For instance, if a company frequently uses a particular type of fastener or connector in its plastic products, standardizing on a single design for these components can lead to significant savings. Instead of creating a new mold for each variation of the fastener or connector, the company can use a single, standardized mold.

This reduces the number of molds that need to be designed, manufactured, and maintained. Additionally, standard parts are often more readily available in the market, which can lead to better pricing from suppliers. Standardization also simplifies the supply chain management, as there are fewer types of parts to source, inventory, and manage, further contributing to cost savings.

Material Sourcing

Supplier Negotiations

Effective negotiations with material suppliers can yield substantial cost savings. By building long - term relationships with suppliers, mold plastic parts companies can gain more leverage in price negotiations. For example, a company that commits to a large - volume purchase of plastic raw materials over an extended period may be able to negotiate a lower price per unit.

Moreover, companies can explore different negotiation strategies, such as negotiating for better payment terms. This could include longer payment periods, which can improve the company's cash flow, or volume - based discounts. Some suppliers may also be willing to offer additional services, such as free delivery or better quality control, as part of the negotiation package. These benefits can contribute to overall cost reduction, even if the price per unit of the material remains the same.

Recycling and Reusing Materials

Recycling and reusing materials is an increasingly important cost - saving and environmentally friendly strategy. Many plastic materials can be recycled and re - introduced into the production process. For example, post - consumer plastic waste can be collected, processed, and used as a feedstock for new mold plastic parts.

The cost of recycled materials is often lower than that of virgin materials. However, there are challenges to consider. The quality of recycled materials may vary, which could potentially affect the quality of the final product. Therefore, proper quality control measures need to be in place when using recycled materials. Additionally, the process of collecting, sorting, and processing recycled materials requires an investment in infrastructure and equipment. But when managed effectively, recycling and reusing materials can lead to significant cost savings, especially in the long term, while also reducing the company's environmental footprint.

Process Improvement

Lean Manufacturing

Implementing lean manufacturing principles can revolutionize the cost - efficiency of mold plastic parts production. Lean manufacturing focuses on eliminating waste in all forms, including overproduction, waiting times, excess inventory, unnecessary transportation, over - processing, defects, and unused talent.

For example, in a mold plastic parts manufacturing facility, reducing overproduction means only producing the number of parts that are actually needed. This prevents the accumulation of excess inventory, which ties up capital and storage space. By optimizing the production layout, companies can reduce the distance that materials and parts need to travel, saving time and energy. Implementing just - in - time (JIT) inventory systems ensures that raw materials arrive at the production line exactly when they are needed, minimizing inventory - holding costs. Overall, lean manufacturing can lead to a more streamlined and cost - effective production process.

Automation

Automation is another key factor in reducing costs in the long run. Automated equipment in mold plastic parts production can significantly improve production precision and efficiency. For example, automated injection molding machines can precisely control parameters such as injection pressure, temperature, and cooling time, resulting in higher - quality parts with fewer defects.

While the initial investment in automated equipment can be substantial, over time, it can lead to significant cost savings. Automated systems can operate continuously with minimal human intervention, reducing labor costs. They also tend to have higher production rates than manual processes, allowing companies to produce more parts in a shorter period. This increased productivity can lead to economies of scale, further reducing the unit cost of each mold plastic part.

Yigu Technology's Perspective

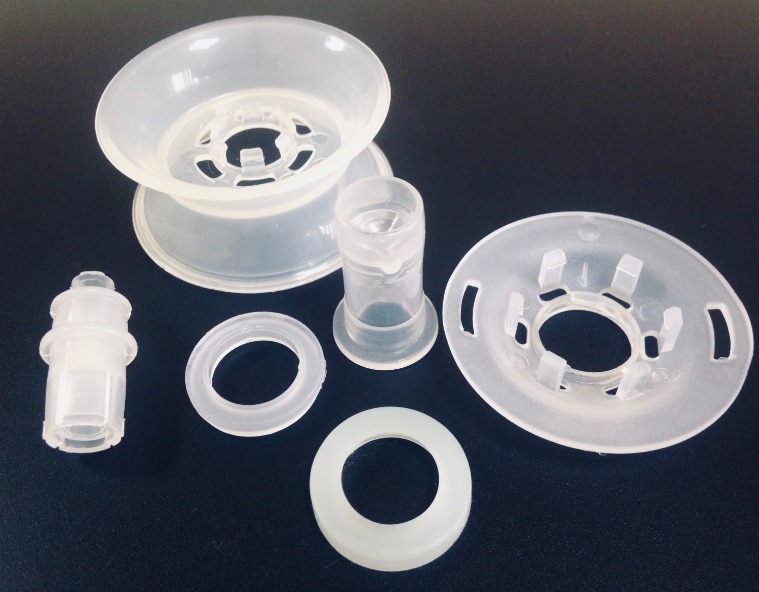

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of cost - effective production in the mold plastic parts industry. We believe that optimizing the design to enhance manufacturability is key. By simplifying complex geometries and standardizing components, we can reduce mold design and manufacturing costs.

Material selection also plays a crucial role. We work closely with suppliers to source high - quality materials at competitive prices, considering both the performance requirements of the parts and cost - saving opportunities. Additionally, we explore the use of recycled materials when appropriate, not only to cut costs but also to contribute to environmental sustainability.

In terms of manufacturing processes, Yigu Technology invests in advanced equipment and lean manufacturing techniques. Our automated production lines improve efficiency, reduce labor costs, and ensure high - quality output. By continuously monitoring and optimizing the production process, we minimize waste and defects, further controlling costs. Overall, we are committed to providing our customers with high - quality non - standard plastic metal products while keeping costs in check.