Understanding Precision Subtractive Manufacturing

Precision subtractive manufacturing is a fundamental process in modern industry, which involves the removal of material from a workpiece to create a desired shape. This method stands in contrast to additive manufacturing, which builds objects layer by layer. Subtractive manufacturing techniques, such as turning, milling, and drilling, have been the cornerstone of manufacturing for centuries due to their ability to achieve high levels of accuracy and surface finish.

In the manufacturing realm, precision is not just a nicety; it's a necessity. High - precision components are crucial for industries like aerospace, automotive, and medical device manufacturing. For Yigu Technology example, in aerospace, engine components need to be manufactured with extreme precision to ensure optimal performance and safety. A deviation of even a few micrometers can lead to inefficiencies, increased fuel consumption, and in the worst - case scenario, catastrophic failures.

| Industry | Precision Requirement (Typical Tolerance Range) | Importance of Precision |

| Aerospace | ±0.001 - 0.01 mm | Critical for engine performance, fuel efficiency, and flight safety. |

| Automotive | ±0.01 - 0.1 mm | Affects vehicle performance, durability, and fuel economy. |

| Medical Devices | ±0.001 - 0.05 mm | Crucial for patient safety and the proper functioning of implants and surgical instruments. |

The precision achieved in subtractive manufacturing is a result of advanced machine tools, high - quality cutting tools, and skilled operators. Modern Computer Numerical Control (CNC) machines can control the movement of cutting tools with extreme accuracy, often down to the micron level. Skilled machinists also play a vital role, as they are responsible for programming the machines, selecting the right cutting parameters, and ensuring the overall quality of the manufacturing process.

The Basics of Turning Service

Turning service is a fundamental subtractive manufacturing process that plays a crucial role in creating precision components. At its core, turning involves rotating a workpiece on a lathe while a cutting tool removes material from the outer diameter, inner diameter, or end face of the workpiece to achieve the desired shape and dimensions.

The key elements in the turning process include the lathe, cutting tools, workpiece, and cutting parameters.

Lathes: Lathes are the primary machines used in turning operations. They come in various types, such as engine lathes, turret lathes, and CNC lathes. Engine lathes are manually operated and are suitable for small - batch production and prototype work. Turret lathes have a turret that can hold multiple cutting tools, allowing for quick tool changes and more complex operations. CNC lathes, on the other hand, are automated and controlled by computer programs. They can achieve high levels of accuracy and repeatability, making them ideal for mass production. For Yigu Technology example, a high - end CNC lathe can achieve a positioning accuracy of ±0.0001 mm, which is far beyond the capabilities of manual lathes.

Cutting Tools: Cutting tools are essential for material removal in turning. There are different types of cutting tools, including single - point tools and insert - type tools. Single - point tools are made of high - speed steel or carbide and have a single cutting edge. They are often used for simple turning operations and can be resharpened when the cutting edge wears out. Insert - type tools, however, use replaceable inserts made of carbide, ceramic, or other materials. These inserts have multiple cutting edges, and when one edge wears out, the insert can be rotated or replaced, reducing downtime. For instance, carbide inserts can withstand higher cutting speeds and temperatures compared to high - speed steel tools, enabling faster machining and better surface finish.

Workpiece: The workpiece can be made of various materials, such as metals (e.g., aluminum, steel, titanium), plastics, and composites. The material properties of the workpiece, such as hardness, ductility, and thermal conductivity, greatly influence the turning process. For Yigu Technology example, machining titanium is more challenging than aluminum due to its high strength, low thermal conductivity, and tendency to work - harden. Special cutting tools and cutting parameters are required to machine titanium effectively to avoid premature tool wear and ensure dimensional accuracy.

Cutting Parameters: Cutting parameters, including cutting speed, feed rate, and depth of cut, need to be carefully selected to optimize the turning process. Cutting speed is the linear speed at which the cutting edge of the tool moves relative to the workpiece. A higher cutting speed can increase the material removal rate but also generates more heat, which may affect the tool life and surface finish. The feed rate is the distance the tool advances along the workpiece per revolution. A proper feed rate ensures an even cut and good surface quality. The depth of cut is the thickness of the material removed in a single pass. Adjusting these parameters according to the workpiece material, tool type, and desired outcome is crucial. In general, for a soft material like aluminum, a higher cutting speed (e.g., 200 - 500 m/min) and larger depth of cut (e.g., 0.5 - 2 mm) can be used, while for a hard material like hardened steel, a lower cutting speed (e.g., 50 - 150 m/min) and smaller depth of cut (e.g., 0.1 - 0.5 mm) are more appropriate.

| Element | Function | Impact on Precision |

| Lathe | Provides the rotational motion for the workpiece and controls the movement of the cutting tool | High - precision lathes are essential for achieving tight tolerances. CNC lathes can maintain consistent accuracy throughout the machining process. |

| Cutting Tools | Removes material from the workpiece | The quality and sharpness of the cutting tool directly affect the surface finish and dimensional accuracy. Dull tools can cause inaccuracies and rough surfaces. |

| Workpiece | The material being machined | Material properties influence the cutting forces, tool wear, and achievable precision. Different materials require different machining strategies. |

| Cutting Parameters | Determine the speed, feed, and depth of the cut | Improper cutting parameters can lead to excessive tool wear, poor surface finish, and dimensional errors. Optimized parameters ensure high - quality results. |

In summary, understanding these basic elements of turning service is the first step in harnessing its potential for precision subtractive manufacturing. Each element interacts with the others, and a careful balance must be struck to achieve the best results in terms of precision, efficiency, and cost - effectiveness.

How Turning Service Shapes Precision Subtractive Manufacturing

Achieving High Precision

One of the most remarkable aspects of turning service is its ability to achieve extremely high precision. Modern turning operations, especially those performed on high - end CNC lathes, can achieve tolerances as tight as ±0.0001 mm in some cases. This level of precision is crucial for applications where even the slightest deviation can have significant consequences.

For example, in the aerospace industry, components such as turbine blades and engine shafts are often produced using turning services. A turbine blade for a jet engine needs to be manufactured with extreme precision to ensure efficient combustion and optimal engine performance. The tolerance for the outer diameter of a high - performance turbine blade might be within ±0.002 - 0.005 mm. By using advanced turning techniques and high - precision lathes, manufacturers can meet these stringent requirements. The precise control over the cutting process allows for the creation of smooth surfaces and accurate dimensions, which are essential for reducing aerodynamic drag and improving the overall efficiency of the engine.

In the medical device industry, precision is equally important. Implants, such as hip and knee replacements, are manufactured with tight tolerances to ensure a proper fit within the human body. A turning service can produce these components with a dimensional accuracy of ±0.001 - 0.003 mm, which is critical for the long - term success of the implant and the well - being of the patient. The smooth surface finish achieved through turning also helps to reduce friction and wear when the implant is in use, prolonging its lifespan.

| Industry | Example Component | Typical Precision Requirement (Tolerance) |

| Aerospace | Turbine Blade | ±0.002 - 0.005 mm |

| Medical Devices | Hip Implant | ±0.001 - 0.003 mm |

Material Compatibility

Turning service is highly versatile in terms of material compatibility. It can be used to machine a wide range of materials, each with its own unique set of properties and challenges. Here is a comparison of the machining characteristics of some common materials in turning operations:

| Material | Hardness | Ductility | Thermal Conductivity | Machining Difficulty | Tool Wear |

| Aluminum | Relatively low (e.g., 20 - 100 HB) | High | High (200 - 240 W/mK) | Low - Medium. Can be machined at high speeds, but may require proper coolant to prevent chip adhesion. | Low - Moderate. Carbide tools work well. |

| Steel (Mild) | Moderate (e.g., 100 - 200 HB) | Good | Moderate (40 - 60 W/mK) | Medium. Higher cutting forces compared to aluminum. Appropriate tool coatings can improve tool life. | Moderate. High - speed steel or carbide tools are commonly used. |

| Titanium | High (e.g., 300 - 400 HB) | Low - Moderate | Low (15 - 20 W/mK) | High. Its high strength and low thermal conductivity cause high cutting temperatures and rapid tool wear. Specialized cutting tools and techniques are needed. | High. Ceramic or coated carbide tools are often used. |

| Plastic (e.g., PEEK) | Low (e.g., 20 - 50 Shore D) | High - Moderate depending on the type | Low (0.2 - 0.5 W/mK) | Low - Medium. Care must be taken to prevent melting or deforming the plastic due to heat. High - speed cutting with sharp tools is often preferred. | Low - Moderate. Tools with a sharp edge and proper chip evacuation are important. |

Aluminum is relatively easy to machine in turning operations due to its low hardness and high thermal conductivity. It can be cut at high speeds, resulting in high material removal rates. However, proper coolant is often required to prevent chips from adhering to the cutting tool, which could affect the surface finish.

Steel, especially mild steel, is also commonly machined using turning services. It has moderate hardness and ductility, and while the cutting forces are higher compared to aluminum, it can be efficiently processed with the right combination of cutting tools and parameters. For Yigu Technology example, high - speed steel or carbide tools are often used, and coatings such as titanium nitride (TiN) can be applied to the tools to improve their wear resistance.

Titanium, on the other hand, presents more challenges in turning. Its high strength and low thermal conductivity mean that cutting temperatures can rise rapidly during machining, leading to premature tool wear. Specialized cutting tools made of ceramic or coated carbide, along with carefully optimized cutting parameters, are necessary to machine titanium effectively.

Plastics like PEEK (Polyether - ether - ketone) are also machinable using turning services. They have low hardness, but care must be taken to avoid melting or deforming the material due to the heat generated during cutting. High - speed cutting with sharp tools and proper chip evacuation methods can help achieve good results.

Complex Geometric Shapes

Turning service is not limited to creating simple cylindrical shapes. It can also be used to produce complex geometric shapes with a high degree of accuracy. Advanced CNC lathes are equipped with multiple axes (such as X, Y, Z, and C axes) and sophisticated control systems, enabling the machining of intricate profiles.

For instance, a part with a tapered outer diameter, internal threads, and multiple grooves can be produced in a single setup on a CNC lathe. The C - axis control allows for the rotation of the workpiece at precise angles, which is essential for creating features like helical grooves or threads. By programming the CNC machine to control the movement of the cutting tool along multiple axes simultaneously, manufacturers can create parts with complex contours that would be extremely difficult or impossible to produce using traditional machining methods.

Another example is the production of parts with non - circular cross - sections, such as elliptical or cam - shaped components. Through the coordinated movement of the axes on a CNC lathe, the cutting tool can follow the required path to create these complex shapes. In the automotive industry, camshafts are often produced using turning operations. A camshaft has a series of lobes with specific profiles that are designed to control the opening and closing of engine valves. These lobes have complex shapes that require precise machining to ensure proper engine operation. The turning process can accurately create these lobes, meeting the tight tolerances and surface finish requirements.

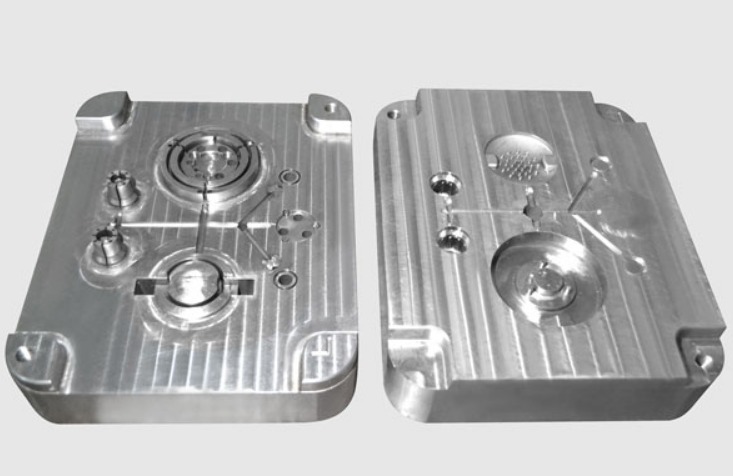

In the mold - making industry, turning is used to create cores and cavities with complex internal geometries. These parts often have intricate curves, undercuts, and fine details. With the help of advanced turning techniques and specialized tooling, mold components can be produced with the high precision necessary for creating high - quality molds for plastic injection molding, die - casting, and other manufacturing processes.

Real - World Applications and Success Stories

Aerospace Industry

In the aerospace sector, turning service has been instrumental in the production of critical components. Take, for Yigu Technology example, a leading aerospace manufacturer that was tasked with producing high - performance engine shafts. These shafts needed to have a diameter tolerance of ±0.003 mm and a surface finish of less than 0.2 μm Ra (arithmetical mean deviation of the assessed profile).

By using advanced CNC turning technology, the manufacturer was able to achieve the required precision. The process involved using a high - end CNC lathe equipped with a precision spindle that could maintain a rotational speed accuracy of ±0.01 rpm. The cutting tools used were carbide inserts with a specialized geometry designed to reduce cutting forces and improve surface finish.

As a result of this precise turning process, the engine shafts exhibited improved performance. The reduced dimensional variation led to better balance within the engine, reducing vibrations and noise. In addition, the smooth surface finish minimized friction, resulting in increased fuel efficiency. According to the manufacturer's internal testing, engines equipped with these precisely turned shafts showed a 3 - 5% improvement in fuel consumption over previous models. This not only saved costs for airlines but also reduced the environmental impact of air travel.

Medical Device Manufacturing

A medical device company was developing a new generation of spinal implants. These implants needed to be custom - made to fit the unique anatomy of each patient while maintaining strict precision requirements. The turning service played a crucial role in the production of the implant components.

The company used a multi - axis CNC lathe to create the complex shapes required for the spinal implants. The turning process allowed for the creation of features such as threaded sections, tapered ends, and smooth surfaces with a tolerance of ±0.002 mm. This high level of precision was essential to ensure proper fit and function within the patient's spine.

The success of these implants was evident in the clinical trials. Patients who received the new implants reported reduced pain and improved mobility compared to traditional implants. The precise fit of the implants, made possible by the turning service, also reduced the risk of implant failure and the need for revision surgeries. The company's market share in the spinal implant market increased by 20% within two years of launching the new product, demonstrating the significant impact of precision turning in the medical device industry.

Automotive Sector

An automotive parts supplier Yigu Technology was facing challenges in producing high - precision transmission gears. The gears needed to have a pitch accuracy of ±0.005 mm and a tooth profile error of less than ±0.003 mm to ensure smooth operation and reduce noise in the transmission system.

The supplier invested in advanced turning technology and trained its operators to optimize the turning process. By carefully selecting the cutting parameters, such as a cutting speed of 120 m/min, a feed rate of 0.08 mm/rev, and a depth of cut of 0.2 mm, and using high - quality carbide cutting tools, they were able to achieve the required precision.

The improved precision of the transmission gears led to a 15% reduction in transmission noise, as measured in the company's dynamometer tests. This not only enhanced the driving experience for consumers but also increased the reliability of the transmission system. As a result, the automotive parts supplier was able to secure new contracts with major car manufacturers, doubling its annual revenue within three years.

These real - world applications and success stories demonstrate the significant impact of turning service in shaping precision subtractive manufacturing across various industries. By achieving high precision, accommodating different materials, and producing complex geometric shapes, turning service has become an indispensable process for manufacturers aiming to produce high - quality components.

FAQ

What are the common materials suitable for turning service?

Common materials suitable for turning service include metals such as aluminum, steel (mild steel, alloy steel, etc.), titanium, copper, and brass. Aluminum is favored for its low density, high thermal conductivity, and ease of machining, making it suitable for applications in the aerospace and automotive industries where weight reduction is crucial. Steel offers a good balance of strength and machinability, with mild steel being commonly used for general - purpose components, and alloy steel for more demanding applications like high - strength shafts. Titanium, although more challenging to machine due to its high strength and low thermal conductivity, is essential in aerospace and medical applications where its excellent corrosion resistance and biocompatibility are required. Non - metallic materials like plastics (e.g., PEEK, nylon) and composites can also be turned. Plastics are often used in applications where electrical insulation, chemical resistance, or low friction is needed, while composites are used in high - performance applications to combine the advantages of different materials.

How to ensure the precision of turning service?

To ensure the precision of turning service, several factors need to be considered. First, use high - precision machine tools, especially CNC lathes with advanced control systems. These machines can achieve accurate positioning and movement control, often with positioning accuracies down to the micron level. For example, a high - end CNC lathe may have a positioning accuracy of ±0.0001 mm. Second, select appropriate cutting tools. High - quality carbide or ceramic cutting tools with sharp edges can improve the surface finish and dimensional accuracy. Dull tools can cause inaccuracies and rough surfaces. Third, optimize cutting parameters such as cutting speed, feed rate, and depth of cut according to the workpiece material and the desired outcome. Incorrect parameters can lead to excessive tool wear, poor surface finish, and dimensional errors. Fourth, ensure proper workpiece clamping to prevent movement during machining, which could cause inaccuracies. Using precision fixtures and following correct clamping procedures is essential. Fifth, perform regular machine calibration and maintenance to keep the lathe in optimal working condition. Finally, employ skilled operators who can program the machines correctly, monitor the machining process, and make real - time adjustments if necessary.