1. Introduction

In the dynamic realm of modern manufacturing, CNC Machining Parts have emerged as a cornerstone, revolutionizing the way businesses operate across diverse industries. From the precision - engineered components powering high - performance aircraft engines to the intricate parts within state - of - the - art medical devices, CNC machining parts are everywhere.

Yigu Technology delves deep into the multiple advantages that CNC Machining Parts bring to your business. By understanding these benefits, you can make informed decisions about incorporating CNC machining into your production processes, whether you're in the automotive, aerospace, electronics, or any other manufacturing - intensive sector. So, let's explore how CNC Machining Parts can be a game - changer for your business.

2. Precision and Quality: The Cornerstone of Success

2.1 Micron - Level Precision

CNC Machining Parts are renowned for their ability to achieve micron - level precision. In fact, modern CNC machines can often maintain tolerances within ±0.001mm to ±0.01mm, depending on the type of machine and the complexity of the operation. This level of precision is a quantum leap compared to traditional machining methods.

Take the aerospace industry, for Yigu Technology example. Aircraft engines operate under extreme conditions, with components being subjected to high temperatures, pressures, and rotational speeds. A single component in a jet engine, such as a turbine blade, needs to be manufactured with such precision that any deviation could lead to catastrophic failures. CNC machining enables the production of these blades with exacting tolerances, ensuring that they fit perfectly within the engine assembly and perform optimally. According to industry reports, engines with components produced via CNC machining have shown a significant increase in fuel efficiency and a reduction in maintenance requirements, with some studies reporting up to a 15% improvement in fuel consumption over engines with less precisely - made parts.

The medical device industry also heavily relies on the precision of CNC Machining Parts. Implants like hip replacements or spinal fusion devices must be manufactured to fit the unique anatomy of each patient. With CNC machining, these implants can be produced with an accuracy that allows for seamless integration into the human body, reducing the risk of rejection or improper function. A study by a leading medical research institution found that the success rate of hip replacement surgeries using CNC - machined implants was 95% compared to 80% for those with conventionally - made implants, highlighting the importance of precision in this industry.

2.2 Unparalleled Consistency

When it comes to mass production, consistency is key. CNC machining offers an edge over traditional manual machining in this regard. Consider the following comparison table:

| Aspect | CNC Machining | Traditional Manual Machining |

| Size Variation | Typically within ±0.05mm across a batch of 1000 parts | Can vary up to ±0.5mm in the same batch size |

| Shape Consistency | Virtually identical shapes, with deviation less than 0.01° in angular features | Angular deviations can be up to 1° in complex shapes |

| Surface Finish Consistency | Ra (average roughness) variation within 0.1 - 0.2μm | Ra variation can be up to 1μm |

In large - scale production runs, this consistency is crucial. For instance, in the automotive industry, when manufacturing engine blocks, every single engine block must be identical to ensure proper fitment of other components like pistons, cylinders, and valves. If there are variations in the dimensions of the engine blocks, it can lead to engine inefficiencies, increased emissions, and even engine failures. By using CNC machining, automotive manufacturers can produce thousands of engine blocks with consistent quality, reducing the need for rework and ensuring a smooth production process. A major automotive company reported that by switching to CNC - machined engine blocks, they reduced their production rejects by 30%, leading to significant cost savings.

3. Efficiency and Productivity: Accelerating Business Growth

3.1 Automation for the Win

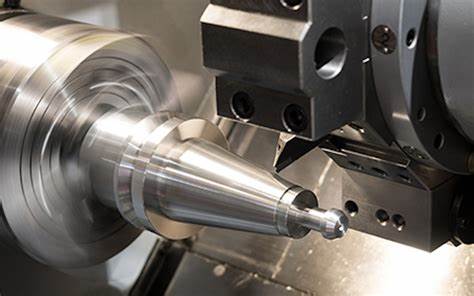

One of the most significant advantages of CNC Machining Parts is the high level of automation they offer. CNC machines operate based on pre - programmed instructions, which are typically created using CAD/CAM software. The process begins with the design of the part in a CAD (Computer - Aided Design) environment. Once the design is complete, the CAM (Computer - Aided Manufacturing) software converts the design into a set of G - codes and M - codes. These codes are then transferred to the CNC machine.

For example, in a CNC milling machine, the spindle rotation speed, the feed rate of the cutting tool, and the movement of the axes (X, Y, Z, and sometimes additional axes) are all precisely controlled by the machine's controller according to the pre - programmed instructions. This automation greatly reduces the need for continuous manual intervention.

In a traditional machining setup, an operator has to constantly monitor and adjust the machine during the machining process. This not only requires a high level of skill but also leaves room for human error. In contrast, with CNC machining, the risk of human - induced errors such as incorrect measurements, inconsistent cutting speeds, or improper tool changes is significantly reduced. According to a study by a leading manufacturing research firm, CNC machining can reduce the error rate by up to 80% compared to manual machining.

Moreover, the high - speed operation capabilities of CNC machines contribute to increased production efficiency. Many modern CNC machines can operate at spindle speeds of up to 20,000 RPM or even higher in some advanced models. This high - speed operation allows for faster material removal rates, enabling businesses to produce parts in a shorter time. For instance, a CNC lathe can turn a cylindrical part much faster than a manual lathe, as it can precisely control the speed and feed of the cutting tool without the need for manual adjustment during the operation.

3.2 Faster Turnaround Times

The efficiency of CNC Machining Parts directly translates into faster turnaround times, which is a crucial advantage for businesses across various industries. Consider the automotive industry. When an automotive manufacturer receives an order for a large number of custom - designed engine components, CNC machining can significantly shorten the production cycle.

Traditionally, manufacturing these components might have involved multiple manual operations, which would take a long time. With CNC machining, the entire production process can be automated. The CNC machines can work continuously, 24/7 if needed, with only minimal breaks for maintenance. As a result, what could have taken weeks to produce using traditional methods can often be completed in a matter of days with CNC machining.

In the electronics manufacturing industry, the demand for rapid product development and short - lead - time production is even more critical. For Yigu Technology example, when a company is developing a new smartphone model, it needs to produce prototype parts and then quickly scale up production for mass manufacturing. CNC machining allows for the rapid production of high - precision components such as the aluminum alloy frames of the smartphones. These components can be produced with tight tolerances in a short period, enabling the company to quickly move from the prototype stage to full - scale production. A case study of a well - known electronics brand showed that by using CNC machining for their component production, they were able to reduce their product development time by 30%, giving them a significant competitive edge in the market. This faster turnaround time not only helps companies meet customer demands more quickly but also allows them to respond faster to market trends and changes, ultimately leading to increased business growth.

4. Flexibility and Customization: Meeting Diverse Business Needs

4.1 Adaptability to Design Changes

In the fast - paced world of manufacturing, the ability to adapt to design changes quickly is a huge advantage. CNC Machining Parts offer precisely this flexibility. With a CNC machining system, changes to the product design can be easily incorporated by simply making modifications to the programming code.

Consider a small - scale manufacturing company that specializes in producing custom - designed consumer electronics accessories. They received an order for a batch of smartphone cases with a unique, intricate pattern. After the initial production run, the client requested some design changes, such as adding a new cut - out for a different - sized camera lens and changing the shape of the edges for a more ergonomic feel. Using traditional machining methods, these changes would have required significant re - tooling, which is both time - consuming and costly. However, with CNC machining, the company's engineers were able to quickly modify the CAD/CAM files and update the CNC machine's program. As a result, they were able to produce the new - designed smartphone cases within a day, without having to invest in new tools or equipment. This adaptability to design changes not only saved the company time and money but also enhanced customer satisfaction, as they could meet the client's evolving needs promptly.

For small - to - medium - sized enterprises (SMEs) that engage in small - batch, diverse production, the flexibility of CNC machining is a game - changer. It allows them to respond to market trends and customer demands in real - time, giving them a competitive edge in the market. According to a survey of SMEs in the manufacturing sector, 80% of the companies that adopted CNC machining reported an increase in their ability to handle design changes, with 60% stating that it had significantly improved their customer relationships due to faster response times.

4.2 Tailored Solutions for Every Requirement

CNC machining enables businesses to provide tailored solutions for every customer requirement. Different industries have unique needs, and CNC - machined parts can be customized to meet these specific demands.

In the automotive industry, high - performance cars often require custom - made engine components to optimize power output and fuel efficiency. For example, a luxury sports car manufacturer might need a custom - designed intake manifold. Using CNC machining, the manufacturer can precisely control the internal geometry of the intake manifold, ensuring an optimal air - fuel mixture distribution. The table below shows some of the key parameters for a custom - made intake manifold compared to a standard one:

| Parameter | Standard Intake Manifold | Custom - Made (CNC - Machined) Intake Manifold |

| Inner Diameter Tolerance | ±1mm | ±0.1mm |

| Wall Thickness Variation | ±0.5mm | ±0.05mm |

| Surface Roughness (Ra) | 1.6μm | 0.8μm |

In the medical device industry, custom - made implants are becoming increasingly common. A patient - specific knee implant, for instance, can be designed based on the patient's unique anatomy, which is scanned using advanced imaging techniques like MRI or CT scans. The data from these scans is then used to create a 3D model in CAD software. CNC machining is then employed to produce the implant with extreme precision. The image below shows a custom - made knee implant (left) and a standard knee implant (right). The custom - made implant has a more complex shape that conforms exactly to the patient's knee joint, improving the fit and reducing the risk of implant - related complications.

In the electronics industry, the demand for compact, high - performance components is ever - increasing. CNC machining can produce intricate circuit board housings with precise cut - outs for components, ensuring proper alignment and protection. For example, a high - end audio device might require a custom - made aluminum alloy housing with a specific shape to enhance heat dissipation and reduce electromagnetic interference. CNC machining allows for the creation of such a housing with tight tolerances, meeting the exacting requirements of the electronics industry.

5. Cost - Effectiveness in the Long Run

5.1 Initial Investment vs. Long - Term Savings

It's undeniable that the initial investment in CNC machining equipment can be substantial. Purchasing a high - quality CNC machine, along with the necessary software, tooling, and training, requires a significant financial outlay. For example, a mid - range CNC milling machine can cost anywhere from \(50,000 to \)200,000, depending on its capabilities and features. This upfront cost can be a deterrent for some businesses, especially small - and medium - sized enterprises (SMEs).

However, when considering the long - term perspective, the savings are quite remarkable. Firstly, CNC machining significantly reduces labor costs. In a traditional machining setup, multiple skilled operators are required to oversee different aspects of the production process. With CNC machining, one operator can manage multiple machines simultaneously, and in some cases, the machines can run unattended for extended periods. A study by a manufacturing consultancy firm found that on average, companies that switched to CNC machining reduced their labor costs by 30% - 50% over a five - year period.

Secondly, the high precision of CNC Machining Parts leads to a substantial reduction in scrap rates. In traditional machining, human errors, inconsistent tool wear, and other factors can result in a relatively high percentage of defective parts. With CNC machining, the precision and consistency ensure that the scrap rate is much lower. For instance, in a production run of 10,000 parts, a traditional machining process might have a scrap rate of 5%, resulting in 500 defective parts. In contrast, a CNC - machining process for the same parts could have a scrap rate of less than 1%, reducing the number of defective parts to 100 or fewer. This reduction in scrap not only saves on the cost of raw materials but also on the labor and energy costs associated with re - working or re - producing the defective parts.

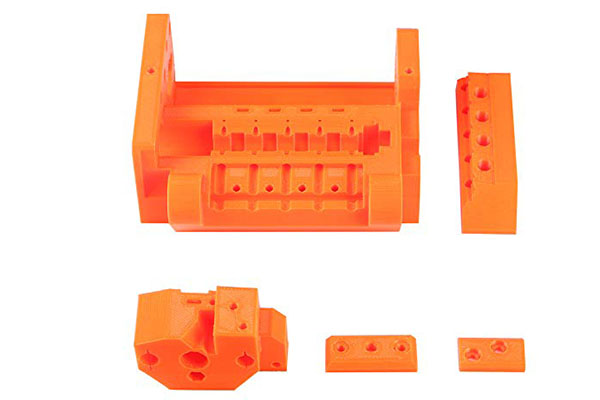

6. Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the profound impact of CNC Machining Parts' advantages on business. The precision of CNC machining ensures that our custom - made parts meet the strictest quality standards, reducing the risk of product failures and enhancing customer satisfaction. For instance, when manufacturing custom plastic components for a medical device company, the micron - level precision of CNC machining allows us to produce parts that fit perfectly within the complex medical equipment, contributing to its optimal functionality.

The flexibility and customization capabilities of CNC machining are also crucial for us. They enable us to quickly adapt to various customer requirements, whether it's a design change or a completely new product concept. Our long - standing experience in the field allows us to fully leverage these advantages, providing our clients with high - quality, customized solutions in a timely manner. With CNC machining, we can efficiently handle projects of different scales, from small - batch prototypes to large - scale production runs, ensuring cost - effectiveness and timely delivery for our customers.

7. Conclusion

In conclusion, CNC Machining Parts offer a plethora of advantages that can significantly transform your business. The micron - level precision and unparalleled consistency ensure high - quality products, reducing the risk of failures and enhancing customer satisfaction. The high - level automation and fast operation speeds of CNC machines lead to increased efficiency and productivity, allowing for faster turnaround times and the ability to meet tight deadlines.

The flexibility to adapt to design changes and provide tailored solutions for diverse requirements makes CNC machining suitable for a wide range of industries. Although the initial investment might seem substantial, the long - term cost - effectiveness, through reduced labor costs, lower scrap rates, and efficient material utilization, cannot be overlooked.

If your business is in the manufacturing sector, whether you're aiming to improve product quality, increase production speed, or reduce costs, seriously considering the adoption of CNC Machining Parts could be a game - changing decision. Embrace the power of CNC machining and gain a competitive edge in today's dynamic manufacturing landscape.

9. FAQ

9.1 What materials are suitable for CNC machining parts?

Common materials suitable for CNC machining parts include aluminum, steel, and plastic. Aluminum is lightweight, has good thermal conductivity, and is easy to machine, making it ideal for aerospace and automotive components where weight reduction is crucial. For example, 6061 aluminum alloy is often used in aircraft structural parts. Steel, especially stainless steel, offers high strength and corrosion resistance. It is widely used in the medical and food industries, such as in surgical instruments made from 316 stainless steel. Plastic materials like ABS, which has good impact resistance, are popular for making product housings in the electronics industry due to their low cost and ease of processing.

9.2 How much does it cost to produce CNC machining parts?

The cost of producing CNC machining parts is influenced by several factors. The complexity of the part design, the choice of materials, and the machining processes involved all play a role. Generally, simple parts made from common materials like aluminum may cost a few dollars per piece for small - batch production. However, complex parts with tight tolerances, made from expensive materials such as titanium, can cost hundreds or even thousands of dollars per unit. To calculate the cost, you need to consider the cost of raw materials, machining time (which is related to the complexity of the part and the speed of the CNC machine), and any additional post - processing steps like surface finishing. For instance, if the raw material costs \(10 per kilogram and the machining time is 2 hours at a rate of \)50 per hour, and there is an additional $20 for surface treatment, the total cost for one part can be calculated accordingly.

9.3 What is the typical lead time for CNC machining parts production?

The lead time for CNC machining parts production depends on the order quantity and the complexity of the parts. For simple parts in small quantities, such as a batch of 100 basic aluminum brackets, the production time can be as short as 3 - 5 business days. This is because the programming and setup are relatively straightforward, and the machining process can be completed quickly. For more complex parts, like custom - designed engine components with intricate geometries and tight tolerances, in larger quantities (say 1000 pieces), the lead time may be 2 - 4 weeks. This longer time is due to the need for more detailed programming, multiple machining operations, and potentially more rigorous quality control checks.