Introduction

In the rapidly evolving landscape of modern manufacturing, 3D printed moulds have emerged as a revolutionary technology, steadily gaining prominence and transforming the way products are designed and produced. Once considered a niche or experimental approach, 3D printed moulds are now at the forefront of innovation, offering manufacturers a host of benefits that traditional mould - making methods simply cannot match.

The manufacturing industry is constantly seeking ways to reduce costs, shorten production cycles, and increase design flexibility. 3D printed moulds have proven to be a game - changer in addressing these challenges. They enable the creation of complex geometries that were previously difficult or impossible to achieve with traditional manufacturing techniques. This has opened up new possibilities for product designers, allowing them to push the boundaries of creativity and develop products with enhanced functionality and aesthetics.

Applications of 3D Printed Moulds

3D printed moulds have found their way into a wide range of industries, revolutionizing the manufacturing processes in each of them.

In the Automotive Industry

In the automotive industry, time is money, and precision is non - negotiable. 3D printed moulds have emerged as a game - changer in this high - stakes environment. For example, when manufacturing engine cylinder block moulds, traditional methods often involve complex machining processes, multiple steps, and long lead times. However, with 3D printing, manufacturers can create these moulds in a fraction of the time.

The use of 3D printed moulds allows for the production of engine cylinder block moulds with complex internal geometries that are optimized for better fuel efficiency and power output. A study by a leading automotive manufacturer found that by using 3D printed moulds for engine components, they were able to reduce the production time of a single mould by 40%, from an average of 10 days to just 6 days. This significant time reduction not only speeds up the overall production line but also allows for faster prototyping and design iterations. Additionally, the complex internal cooling channels that can be easily incorporated into 3D printed engine moulds improve the performance of the engine by up to 15%, leading to better - performing vehicles that consume less fuel.

In the Aerospace Field

Aerospace is an industry where weight reduction, precision, and high - performance materials are of utmost importance. 3D printed moulds have become an essential tool for aerospace manufacturers. When it comes to manufacturing moulds for complex aviation parts such as turbine blades or aircraft structural components, 3D printing offers unparalleled advantages.

For instance, the internal lattice structures of 3D printed moulds can be designed to be lightweight yet incredibly strong, which is crucial for aerospace applications. These lattice structures mimic the natural strength - to - weight ratio of materials like bone, reducing the weight of the final part without sacrificing its structural integrity. A major aerospace company reported that by using 3D printed moulds for manufacturing aircraft wing components, they achieved a weight reduction of 20% in the final product. This weight reduction directly translates into increased fuel efficiency, longer flight ranges, and lower operating costs. Moreover, 3D printed moulds can achieve tolerances as tight as ±0.05mm, ensuring that the high - precision requirements of aerospace components are met. This level of precision is vital for the safety and performance of aircraft, as even the slightest deviation can have catastrophic consequences.

In the Consumer Goods Sector

The consumer goods sector is all about rapid innovation, cost - effectiveness, and meeting the ever - changing demands of consumers. 3D printed moulds have become a powerful asset in this dynamic market. Consider the production of toys, where creativity and design flexibility are key. With 3D printed moulds, toy manufacturers can quickly bring new and innovative toy designs to market.

For example, a small toy startup used 3D printed moulds to create a line of customizable action figures. By using 3D printing, they were able to reduce the time from concept to production from 6 months (using traditional mould - making methods) to just 2 months. This rapid turnaround time allowed them to respond quickly to market trends and consumer demands. In the electronics industry, 3D printed moulds are used to create smartphone and tablet cases. The ability to quickly design and produce new moulds means that manufacturers can keep up with the fast - paced changes in consumer preferences for different colors, textures, and designs. A well - known electronics brand reported that by using 3D printed moulds for their product cases, they were able to introduce 3 new design variations per quarter, compared to only 1 per quarter with traditional moulds, significantly increasing their market share in the highly competitive consumer electronics market.

As we can see from the comparison, 3D printed moulds offer distinct advantages in terms of cost - effectiveness for small - scale production, speed, and design flexibility. However, traditional moulds still hold their ground in high - volume production scenarios where a high - quality surface finish and long - term durability are critical.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology firmly believes in the transformative power of 3D printed moulds in custom manufacturing. The ability to quickly produce custom - designed moulds with complex geometries allows us to meet the unique demands of our clients more efficiently. For small - batch and high - customization projects, 3D printed moulds significantly reduce lead times and costs, enabling us to offer more competitive pricing and faster delivery.

We've witnessed firsthand how 3D printed moulds can enhance product development, especially when creating prototypes or specialized parts. With continuous advancements in 3D printing materials and technologies, we are confident that 3D printed moulds will play an even more significant role in the future of non - standard product manufacturing, and we are excited to be at the forefront of this innovative trend.

FAQ

What materials can be used for 3D printed moulds?

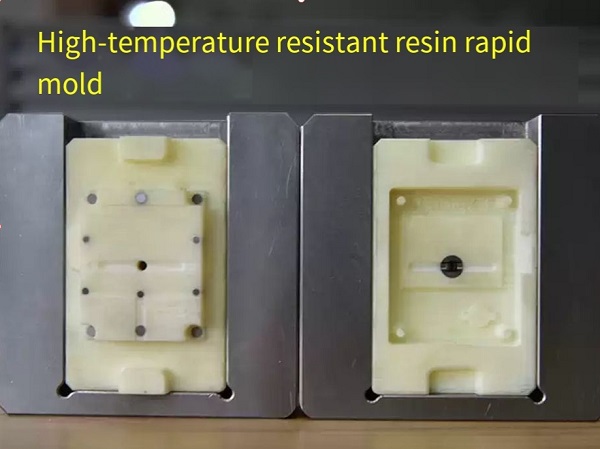

A variety of materials can be used for 3D printed moulds. Polymer plastics like acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and nylon are commonly used due to their relatively low cost, ease of printing, and good mechanical properties for many applications. For more demanding applications, metal - based materials such as aluminum - based alloys, stainless steel, and even some high - temperature - resistant alloys can be used in metal 3D printing processes like selective laser melting (SLM). There are also emerging ceramic - based materials for 3D printing, which can offer high - temperature resistance and chemical stability. The range of available materials is constantly expanding, with new composite materials being developed to combine the advantages of different substances, providing more options for specific mould - making requirements.

Are 3D printed moulds suitable for large - scale production?

3D printed moulds can be suitable for large - scale production under certain conditions. In some cases where the design complexity is high and traditional mould - making methods would be extremely costly or time - consuming to replicate, 3D printed moulds can offer an edge even in large - scale production. However, compared to traditional injection - moulding with metal moulds for very high - volume production (e.g., millions of units), 3D printed moulds may have limitations. Their relatively slow printing speed can increase the overall production time, and the cost per unit may be higher due to material costs. But for mid - scale production runs (say, from a few thousand to a hundred thousand units) where design flexibility and shorter lead times are important, 3D printed moulds can be a viable option. They also shine in scenarios where frequent design changes are needed during large - scale production, as new 3D printed moulds can be quickly produced.

How accurate are 3D printed moulds?

The accuracy of 3D printed moulds has significantly improved over the years. Currently, many 3D printers can achieve an accuracy of ±0.1 - 0.2mm for general - purpose applications. High - end industrial 3D printers can reach even higher precision, with some capable of achieving tolerances as tight as ±0.01 - 0.05mm. The accuracy depends on various factors, including the 3D printing technology used (e.g., stereolithography generally offers high precision), the quality of the printer, and post - processing techniques. To further improve accuracy, measures such as using high - resolution printers, optimizing printing parameters, and performing precise post - processing like milling or polishing can be taken. As 3D printing technology continues to evolve, we can expect even higher levels of accuracy in the future, making 3D printed moulds suitable for an even wider range of high - precision manufacturing applications.