Introduction

In the rapidly evolving landscape of modern manufacturing, 3D prototype printing has emerged as a revolutionary technology, playing a pivotal role in various industries. From aerospace and automotive to healthcare and consumer goods, its impact is far - reaching. This technology allows for the creation of three - dimensional objects directly from digital models, layer by layer. But how exactly does 3D prototype printing work? What are its benefits, limitations, and applications? And most importantly, how can it solve the problems faced by manufacturers and product developers?

This article aims to comprehensively address these questions, providing you with in - depth knowledge about 3D prototype printing. Whether you are a seasoned engineer, a startup entrepreneur, or a design enthusiast, understanding 3D prototype printing can open up new possibilities for your projects, from reducing development time to creating highly customized products.

How Does 3D Prototype Printing Work?

3D Printing Basics

3D prototype printing starts with a digital model, which is typically created using computer - aided design (CAD) software or obtained through 3D scanning. This digital model serves as the blueprint for the physical object. In contrast to traditional manufacturing techniques such as subtractive manufacturing (e.g., milling, turning, where material is removed from a larger block to create the desired shape) and formative manufacturing (e.g., casting, forging, which shape materials through molding or pressure), 3D printing is an additive manufacturing process.

For example, in traditional injection molding, a mold is created first, and then molten plastic is injected into it. If there are design changes, a new mold has to be made, which is time - consuming and costly. In 3D printing, design modifications can be easily made to the digital model, and a new prototype can be printed immediately.

Layers Building Process

Once the digital model is ready, it is sliced into thin layers by specialized software. Each layer represents a cross - section of the final object. The 3D printer then works by depositing or solidifying materials layer by layer, following the instructions from the sliced model.

When it comes to materials, plastic is one of the most commonly used. For instance, in the Fused Deposition Modeling (FDM) 3D printing technology, a spool of thermoplastic filament (such as ABS or PLA) is fed into the printer. The printer's extruder heats the filament until it becomes molten and then extrudes it through a nozzle, depositing it layer by layer on the build platform. Each layer bonds with the previous one as it cools and solidifies.

Metal 3D printing, on the other hand, often uses powder - based materials. In Selective Laser Melting (SLM) or Electron Beam Melting (EBM) processes, a high - energy laser or electron beam is used to selectively melt metal powder particles layer by layer. The metal powder is spread evenly across the build platform, and the beam fuses the powder in the areas defined by the digital model. Once a layer is completed, a new layer of powder is added, and the process repeats. This allows for the creation of complex metal structures that would be extremely difficult or even impossible to produce with traditional metal - working methods.

Applications of 3D Prototype Printing

In the Automotive Industry

3D prototype printing has become an indispensable tool in the automotive industry. Many leading car manufacturers, such as Ford, have integrated 3D printing into their R&D processes. Ford uses 3D printing to create prototypes of new engine components. In the past, developing a new engine part using traditional methods could take months. Designers had to create detailed blueprints, then wait for the production of molds and the manufacturing of the physical part through processes like casting or machining. If any design flaws were discovered during testing, the entire process had to be repeated, which was time - consuming and costly.

With 3D printing, Ford can now create a prototype of an engine component in a matter of days. They first design the part using CAD software, and then directly print it using metal 3D printing technology. This allows them to quickly test the functionality of the new design, make modifications to the digital model based on the test results, and print a new prototype. As a result, the development time for new engine components has been significantly reduced, and the cost of R&D has decreased by up to 50% in some cases.

In the Medical Field

In the medical field, 3D printing is revolutionizing patient care, especially in the production of customized medical implants and prosthetics. For example, in the case of hip replacement surgeries, traditional implants are often mass - produced in standard sizes. However, every patient's anatomy is unique, and a standard implant may not fit perfectly, leading to potential complications such as loosening over time or discomfort for the patient.

3D printing has changed this scenario. Surgeons can now use 3D scanning technology to create a detailed digital model of a patient's hip joint. Based on this model, a customized hip implant can be 3D - printed. A study at a leading hospital found that patients who received 3D - printed customized hip implants had a 30% faster recovery time compared to those with standard implants. The customized implants fit the patients' anatomy precisely, reducing the risk of post - operative complications and improving the overall quality of life for the patients.

In Product Design

For product designers, 3D printing offers a way to quickly transform their ideas into tangible prototypes. Take the example of a consumer electronics company that wants to design a new smartphone case. In the past, designers would have to create a 2D sketch, then work with a manufacturer to create a mold for the case. This process could take weeks, and it was difficult to get early feedback from potential customers.

Now, with 3D printing, designers can create a 3D model of the smartphone case in CAD software and print a prototype within a day. They can then show this prototype to focus groups or potential customers to gather feedback. Based on the feedback, they can easily modify the 3D model and print another prototype. This iterative process allows designers to refine their designs quickly, resulting in a better - designed product that meets the needs and preferences of the market.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values 3D prototype printing. We believe this technology brings new opportunities to product development. With 3D printing, we can realize complex designs that were previously difficult to achieve with traditional manufacturing methods, which greatly expands the possibilities of product innovation. It also significantly improves the efficiency of the prototype - making process, allowing us to quickly turn our clients' ideas into physical samples. This not only reduces the time - to - market for products but also helps in cost - effective product development. We are committed to working closely with our clients, leveraging 3D prototype printing technology to jointly create innovative products that meet market demands.

FAQs about 3D Prototype Printing

What materials can be used for 3D prototype printing?

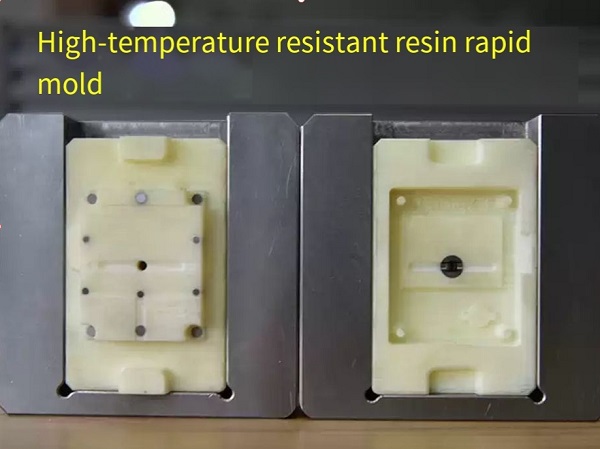

A wide range of materials can be used for 3D prototype printing. Plastics like PLA (Polylactic Acid) are popular due to their ease of use and environmental - friendliness, often used in home and educational 3D printing. ABS (Acrylonitrile Butadiene Styrene) is another common plastic, known for its strength and heat - resistance, suitable for more industrial and functional prototypes. Metals such as aluminum alloys, which are lightweight and corrosion - resistant, are used in automotive and aerospace applications. Titanium alloys, with their high strength - to - weight ratio and excellent corrosion resistance, are employed in high - end applications like medical implants and aircraft components. Ceramics can be 3D - printed to create intricate artworks and components that require high - temperature resistance. Resins, especially 光敏 resins used in SLA (Stereolithography) 3D printing, are valued for their high precision and smooth surface finish, ideal for making detailed models.

How accurate is 3D prototype printing?

The accuracy of 3D prototype printing depends on various factors, including the type of 3D printer and the materials used. Generally, industrial - grade 3D printers can achieve high precision, with an accuracy range of 0.1 - 0.01 millimeters. For example, in the production of jewelry prototypes, high - precision 3D printers can accurately reproduce fine details, such as delicate filigree patterns, with an accuracy of around 0.05 millimeters. In the automotive industry, when printing engine components prototypes, an accuracy of 0.1 - 0.2 millimeters may be sufficient for initial functional testing. However, for applications like micro - electronics or dental prosthetics, even higher precision (down to 0.01 millimeters or less) might be required to ensure a perfect fit and proper functionality.

Can I print large - scale prototypes with 3D printing?

While 3D printers have limitations in the size of objects they can print in a single piece, there are ways to create large - scale prototypes. Many industrial 3D printers have large build volumes, some with dimensions reaching several meters. Additionally, techniques such as slicing the model into smaller parts and then assembling them after printing can be used. For instance, in the creation of large - scale art sculptures, the model can be divided into sections, each printed separately, and then joined together using adhesives or mechanical fasteners. In the construction industry, large - scale 3D - printed building models are made by printing multiple components and assembling them on - site. There are also large - format 3D printers specifically designed for large - scale applications, like the construction of 3D - printed houses, where the printer can build walls and other structural elements layer by layer on a large scale.