Polyetheretherketone (PEEK) stands at the pinnacle of high-performance plastics, but molding it presents unique challenges that can frustrate even experienced manufacturers. Its extreme high-temperature resistance demands specialized equipment, and even minor deviations in processing can lead to costly defects like voids or warpage. Achieving consistent mechanical strength across batches is another hurdle, especially for critical applications like medical implants. Many also struggle with the material’s high viscosity, which can cause short shots or uneven filling. This guide addresses these pain points, offering expert insights into PEEK’s properties, molding processes, and more to help you produce reliable, high-quality parts.

Material Properties of Polyetheretherketone (PEEK): Unrivaled Performance

Polyetheretherketone (PEEK) is celebrated for its exceptional properties, making it a top choice for extreme environments. Its high-temperature resistance is unmatched among thermoplastics—it can withstand continuous use at 260°C and short-term exposure to 300°C, far outperforming materials like nylon or PC. This makes it ideal for applications near engines or in industrial ovens.

Mechanical strength is another standout feature, with a tensile strength of 90–100 MPa and a flexural modulus of 3.6–4.1 GPa, rivaling some metals. Even at elevated temperatures, PEEK retains most of its strength—critical for load-bearing parts in aerospace and automotive systems.

Chemical resistance is exceptional: PEEK resists fuels, oils, acids, and alkalis, making it suitable for chemical processing equipment and oilfield components. Its wear resistance is also impressive, with a low friction coefficient (0.3 dry, against steel), ensuring longevity in moving parts like bearings.

For medical applications, biocompatibility is key—PEEK is FDA-approved for implants, as it doesn’t trigger immune responses and integrates well with bone. It also offers excellent dimensional stability (coefficient of thermal expansion: 45 ppm/°C) and flame retardancy (UL94 V-0 rating without additives). Its electrical properties, including high dielectric strength, make it useful for high-temperature electronics.

Injection Molding Process for PEEK: Taming the Extremes

PEEK injection molding requires specialized equipment and precise control due to its high processing temperatures. Drying requirements are strict: PEEK absorbs minimal moisture but must be dried at 150–160°C for 4–6 hours to remove surface moisture, preventing hydrolysis during molding.

Melt temperature is critical, ranging from 380–400°C—far higher than most plastics. Exceeding 410°C causes degradation, reducing strength and causing discoloration. Injection pressure must be high (120–180 MPa) to overcome PEEK’s high viscosity, especially for thin-walled parts.

Injection speed should be moderate (30–60 mm/s) to avoid shear heating, which can degrade the material. Cooling time is lengthy (30–60 seconds) due to PEEK’s low thermal conductivity, contributing to a cycle time of 60–120 seconds—significantly longer than other plastics.

High-temperature processing demands specialized machinery with heated barrels and nozzles capable of maintaining 400°C. Runner and gate design must accommodate high viscosity—large, short runners and direct gates minimize pressure drop. Process optimization often involves incremental adjustments to temperature and pressure, as PEEK is less forgiving than standard plastics.

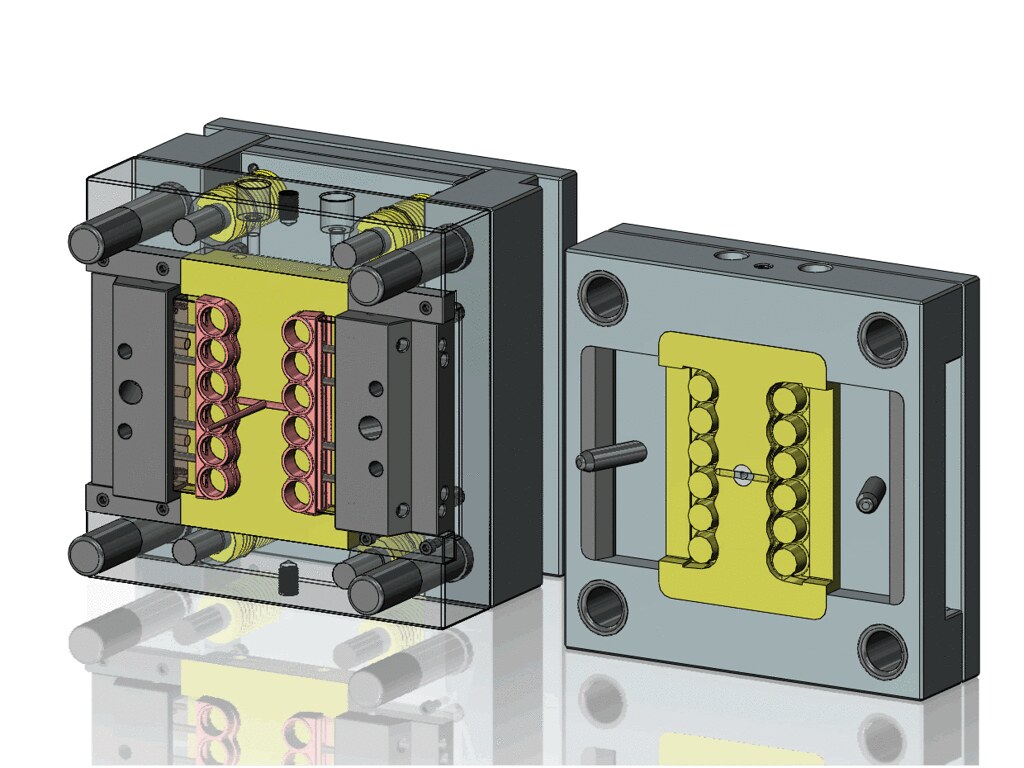

Mold Design for PEEK Molding: Built for the Heat

Mold design principles for PEEK focus on withstanding high temperatures and managing viscosity. PEEK mold materials must resist heat and wear—H13 tool steel is standard, as it retains hardness at 400°C. For high-volume production, nickel-plated molds improve release and durability.

Mold flow analysis is essential to simulate filling, as PEEK’s high viscosity can lead to uneven flow. Cooling channel layout should be dense and uniform, with channels 8–10 mm from the cavity to accelerate cooling and reduce cycle time. Water temperatures of 80–100°C prevent thermal shock to the mold.

Venting requirements are critical—PEEK traps air easily, so vents 0.02–0.03 mm deep at flow ends and parting lines are necessary to prevent voids. Draft angles of 1–2° facilitate ejection, though PEEK’s rigidity may require slightly larger angles than softer plastics.

Ejector pin design must distribute force to avoid deformation—use multiple large pins, as PEEK’s strength can resist ejection. Hot runner systems with heated manifolds (380–400°C) reduce waste and improve consistency, though they require precise temperature control. Surface finish of the mold should be smooth (Ra < 0.8 μm) to prevent surface defects in the final part.

Quality Control and Defects in PEEK Molding: Ensuring Perfection

PEEK’s high performance demands rigorous quality control methods. Common defects and solutions include:

| Defect | Cause | Solution |

| Voids | Trapped air or moisture | Add vents; extend drying time. |

| Warpage | Uneven cooling or residual stress | Optimize cooling channels; reduce packing pressure. |

| Short shots | Insufficient pressure or low melt temp | Increase pressure; raise temperature to 390–400°C. |

| Surface defects | Mold contamination or degradation | Clean mold; lower melt temperature. |

| Sink marks | Inadequate packing | Increase packing time/pressure. |

Statistical process control (SPC) monitors variables like melt temperature and pressure, with allowable deviations of ±5°C and ±5 MPa to ensure consistency. Inspection techniques include CMMs for dimensional accuracy (tolerances as tight as ±0.02 mm for medical parts) and ultrasonic testing to detect internal voids.

Root cause analysis is vital for recurring issues—for example, if warpage occurs, checking cooling channel symmetry or mold temperature uniformity can identify the source. Regular material testing (tensile strength, impact resistance) ensures batches meet specifications.

Applications of PEEK in Injection Molding: Where Performance Matters

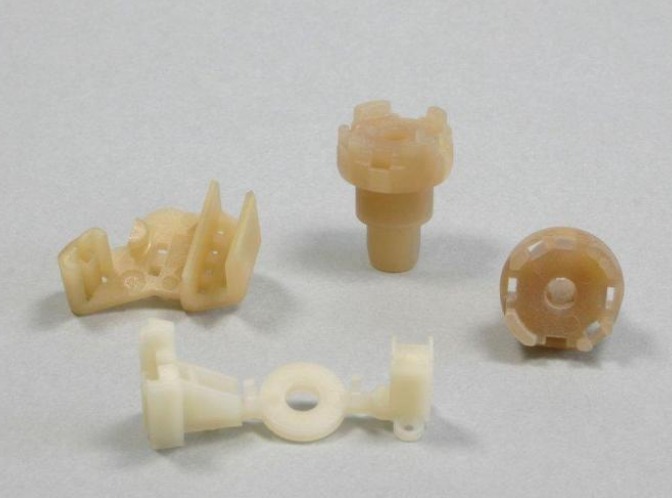

PEEK’s unique properties make it indispensable in demanding applications:

- Aerospace components: Engine brackets and wire insulation leverage high-temperature resistance and low weight.

- Medical implants: Spinal cages and hip replacements use PEEK’s biocompatibility and bone-like stiffness.

- High-performance mechanical parts: Bearings and gears in industrial pumps resist wear and chemicals.

- Electronics components: Connectors in high-temperature environments (e.g., under-the-hood automotive) rely on electrical insulation.

- Automotive parts: Turbocharger components withstand extreme heat and oil exposure.

Design for manufacturing tips: Use wall thicknesses of 1–5 mm (thinner sections may need higher pressure), and avoid sharp corners to reduce stress. For biomedical applications, ensure parts are machined to smooth finishes to prevent bacterial growth.

Post-Processing and Finishing of PEEK Parts: Refining Excellence

Post-molding operations for PEEK require care due to its high melting point. Machining and trimming are common—PEEK can be turned, milled, or drilled with carbide tools, though slow speeds prevent heat buildup (which can exceed its glass transition temperature of 143°C).

Adhesive bonding works with epoxy or cyanoacrylate adhesives, though surface treatment (plasma etching) improves bond strength. Ultrasonic welding is possible but requires high energy due to PEEK’s rigidity.

Surface treatments include polishing to enhance wear resistance or coating with PTFE to reduce friction. Heat treatment (annealing at 200°C for 2 hours) relieves residual stress, improving dimensional stability—critical for precision parts.

Assembly tolerances account for minimal thermal expansion, allowing tight fits in aerospace and medical assemblies. Finishing standards are strict: medical parts require USP Class VI certification, while aerospace components must meet AS9100 standards.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology specializes in PEEK injection molding. We understand the material’s nuances, from precise high-temperature processing to ensuring biocompatibility for medical parts. Our expertise in mold flow analysis and process optimization minimizes defects, while strict quality control methods guarantee consistency. Whether you need aerospace components or medical implants, we deliver PEEK parts that meet the most demanding performance standards, leveraging advanced equipment and years of experience.

FAQs

- What makes PEEK more expensive than other plastics?

PEEK’s complex synthesis process and high-performance properties (high-temperature resistance, biocompatibility) drive up costs. However, its longevity and ability to replace metal often justify the investment in critical applications.

- Can PEEK be recycled?

Yes, but recycled PEEK (rPEEK) has slightly reduced mechanical properties. It’s suitable for non-critical parts, while virgin PEEK is recommended for implants or aerospace components.

- What equipment is needed for PEEK injection molding?

Specialized machines with heated barrels (up to 420°C), high-pressure capabilities (≥180 MPa), and precise temperature control are required. Molds must be made from heat-resistant steel (e.g., H13) to withstand repeated exposure to 400°C.