Introduction

What are Plastic Crown Gears?

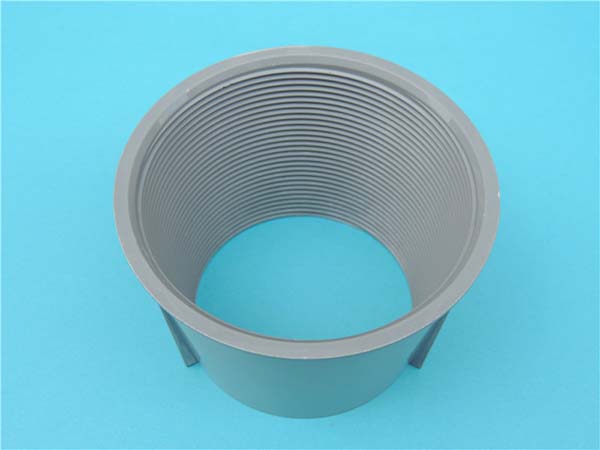

Plastic crown gears are a specialized type of gear within the mechanical components family. They are characterized by their unique shape, which resembles a crown - hence the name. Structurally, they have teeth that are set at an angle on a conical surface. This angled tooth arrangement allows for a smooth transfer of motion between non - parallel shafts, typically at a 90 - degree angle.

These gears are made from various types of plastics, such as acetal (Delrin), nylon, and polypropylene. Each plastic material has its own set of properties. For example, acetal is known for its high stiffness, dimensional stability, and low friction, making it a great choice for applications where precision and durability are required. Nylon, on the other hand, has excellent wear resistance and can handle higher loads in some cases, while polypropylene is often chosen for its cost - effectiveness and chemical resistance.

In a mechanical system, plastic crown gears are commonly found in applications like small - scale power transmission systems, such as those in printers, small motors, and some household appliances. They are also used in certain types of actuators and in the gearing mechanisms of some medical devices due to their light - weight and non - magnetic properties.

Significance in Mechanical Applications

Plastic crown gears play a crucial role in modern mechanical applications. In today's world, where efficiency, cost - effectiveness, and miniaturization are highly valued, these gears offer several advantages over their metal counterparts.

Firstly, their lightweight nature reduces the overall weight of the mechanical system. This is especially beneficial in applications where weight is a critical factor, such as in portable devices or aerospace components. For instance, in a small, handheld power tool, the use of plastic crown gears can make the tool easier to handle and operate for extended periods.

Secondly, plastic crown gears are often more cost - effective to manufacture. The injection - molding process used to create plastic gears is generally less expensive than the complex machining processes required for metal gears. This cost - savings can be passed on to the end - user, making products more affordable.

How Plastic Crown Gears Enhance Efficiency

Reduced Friction and Wear

Lower Friction Coefficient

One of the key factors contributing to the efficiency enhancement of plastic crown gears is their lower friction coefficient. In general, plastic materials used in these gears, such as acetal and nylon, have a significantly lower friction coefficient compared to common metal materials for gears. For example, the friction coefficient of acetal can be around 0.2 - 0.3, while that of steel gears is typically in the range of 0.6 - 0.8 when operating under similar conditions without lubrication.

This lower friction coefficient means that when plastic crown gears are in operation, less energy is wasted in overcoming the frictional forces between the teeth of the gears. In a mechanical system, energy losses due to friction can be substantial over time. With plastic crown gears, the reduced friction leads to less heat generation as well. Heat generated from friction not only wastes energy but can also cause problems such as thermal expansion, which may affect the precision of the gear operation. By minimizing friction, plastic crown gears can maintain a more stable operation and transfer power more efficiently. For instance, in a small - scale electric motor used in a household appliance, the use of plastic crown gears can result in a 10 - 15% reduction in energy losses related to friction compared to using metal gears, leading to a more energy - efficient motor operation.

Wear - Resistance Features

Plastic materials also endow crown gears with excellent wear - resistance features. Many plastics have a self - lubricating property to some extent. Nylon, for example, contains amide groups in its molecular structure, which can form a thin lubricating film on the surface of the gear during operation. This film reduces the direct contact between the teeth of the gears, thus minimizing wear.

Moreover, the molecular structure of plastics allows them to withstand repeated mechanical stresses during gear meshing better than some metals in certain situations. Metals, especially those without proper surface treatment, may be prone to surface fatigue and pitting over time due to the cyclic loading in gear operation. In contrast, plastic crown gears can maintain their tooth shape and integrity for a longer time. A study showed that in a continuous operation test of 1000 hours, a plastic crown gear made of a high - performance engineering plastic experienced only a 0.05mm wear on the tooth surface, while a similar - sized metal gear without special surface treatment had a wear depth of 0.15mm.

The longer service life of plastic crown gears due to their wear - resistance means less frequent replacement, reducing maintenance costs. This not only saves time and labor for maintenance but also minimizes the downtime of the mechanical system. For industrial production lines, reducing downtime can significantly improve overall production efficiency.

Lightweight Design

Impact on Energy Consumption

The lightweight nature of plastic crown gears has a direct and positive impact on energy consumption in mechanical systems. Plastic materials are much lighter than metals. For example, the density of nylon is approximately 1.15 g/cm³, while that of steel is around 7.85 g/cm³. When plastic crown gears are used in a mechanical system, the overall weight of the moving parts is reduced.

In applications where the mechanical system needs to move or rotate the gears continuously, such as in a conveyor belt system or a robotic joint, a lighter gear means less energy is required to accelerate and decelerate the components. According to energy - conservation principles, the kinetic energy \(E_k=\frac{1}{2}mv^2\), where \(m\) is the mass and \(v\) is the velocity. With a lower - mass plastic crown gear (\(m\) is smaller), the energy required to achieve the same velocity \(v\) is reduced. In a small - scale conveyor system, replacing metal crown gears with plastic ones can lead to a 20 - 30% reduction in the energy consumption of the motor driving the conveyor, as the motor has to do less work to move the lighter components.

Easier to Operate and Accelerate

In addition to energy savings, the lightweight design of plastic crown gears makes mechanical components easier to operate and accelerate. In some handheld power tools, such as electric screwdrivers or cordless drills, the use of plastic crown gears in the gearing mechanism allows for quicker acceleration of the drill bit or screwdriver head. Since the gears are lighter, the motor can reach the desired rotational speed more rapidly.

This ease of acceleration also benefits high - speed rotating machinery. In some precision instruments with high - speed rotating shafts, like certain types of optical scanners or small - scale centrifuges, plastic crown gears enable faster start - up and more precise speed control. The reduced inertia of the lightweight plastic gears means that the system can respond more quickly to changes in the input power or control signals, improving the overall efficiency and performance of the equipment.

Noise and Vibration Reduction

Sound - Dampening Properties

Plastic materials possess excellent sound - dampening properties, which is a significant advantage of plastic crown gears over their metal counterparts. Metals are good conductors of sound, and when metal gears mesh and rotate, the mechanical vibrations are easily transmitted and amplified, resulting in relatively high - pitched and loud noises.

On the other hand, plastics have a more complex molecular structure with a certain degree of elasticity. This elasticity allows plastics to absorb and dissipate the energy of mechanical vibrations rather than transmit them as sound waves. For example, in a comparison test between a metal crown gear and a plastic one in a small - scale gearbox, the noise level of the metal gear operation was measured at 70 dB(A) at a rotational speed of 1000 rpm, while the plastic crown gear reduced the noise level to 55 dB(A) under the same conditions. This significant reduction in noise not only makes the operation of the mechanical system more pleasant but also reduces the need for additional noise - insulation measures, saving costs and space.

Smooth Operation and Vibration Absorption

Plastic crown gears also contribute to smooth operation by effectively absorbing vibrations. During the meshing process of gears, there are inevitable small - scale impacts and vibrations due to manufacturing tolerances and the nature of the gear - meshing motion. The elastic nature of plastic materials can cushion these impacts.

When a plastic crown gear experiences a vibration, its molecular chains can stretch and bend slightly, converting the kinetic energy of the vibration into internal energy within the material, which is then dissipated as heat in a controlled manner. This vibration - absorption property helps to ensure the smooth operation of the mechanical system. In a printing press, for example, the use of plastic crown gears in the paper - feeding mechanism can prevent vibrations from being transmitted to the printing head, ensuring high - quality and consistent printing results. By reducing vibrations, plastic crown gears also help to prevent premature wear and damage to other components in the mechanical system, further enhancing the overall efficiency and reliability of the system.

Real - World Applications and Efficiency Data

Automotive Industry

In the automotive industry, plastic crown gears have found their way into various critical components, contributing significantly to enhancing vehicle efficiency.

Transmission Systems: Many modern cars use plastic crown gears in their automatic or manual transmission systems. For example, in some compact cars like the Honda Fit, plastic crown gears are employed in the auxiliary transmission mechanisms. These gears help in smooth gear - shifting operations. By reducing the weight of the transmission components, they contribute to better fuel efficiency. Studies have shown that using plastic crown gears in the transmission of a compact car can lead to a 3 - 5% improvement in fuel efficiency. This is because the lighter gears require less energy to rotate, reducing the overall load on the engine.

Steering Systems: In electric power - assisted steering (EPAS) systems, plastic crown gears play a crucial role. For instance, in the Ford Focus, the EPAS system utilizes plastic crown gears to transfer the rotational motion from the electric motor to the steering column. The low - friction and lightweight properties of plastic crown gears enable more precise steering control. They also reduce the energy consumption of the EPAS system by up to 10 - 15%. Since the gears can move with less resistance, the electric motor in the EPAS system doesn't have to work as hard, resulting in energy savings and a longer - lasting motor.

Robotics

Plastic crown gears are essential components in robotic systems, significantly improving their performance and efficiency.

Joint Actuation: In humanoid robots such as the Boston Dynamics' Atlas, plastic crown gears are used in the joint actuators. These gears enable precise control of the robot's movements. The reduced weight of the plastic crown gears compared to metal gears means that the robot's joints can accelerate and decelerate more quickly. This leads to a more natural and responsive movement. In a test, when a metal - gear - based robot joint and a plastic - gear - based robot joint were compared, the plastic - gear - based joint could achieve a 20% faster response time when changing the direction of movement.

Moreover, plastic crown gears contribute to energy savings in robots. Since they require less energy to operate due to their lightweight and low - friction characteristics, the overall power consumption of the robot is reduced. In a small - scale educational robot, replacing metal crown gears with plastic ones can result in a 30 - 40% reduction in power consumption during normal operation, allowing the robot to operate for a longer time on a single battery charge.

Consumer Electronics

Plastic crown gears are widely used in small - motor - driven consumer electronics, bringing about improvements in energy efficiency and product lifespan.

Electric Toothbrushes: Brands like Philips Sonicare use plastic crown gears in their electric toothbrush designs. These gears are part of the gearing mechanism that transfers the rotational motion from the small electric motor to the brush head. The low - noise and wear - resistant properties of plastic crown gears ensure a quiet and long - lasting operation. They also contribute to energy savings. A study showed that an electric toothbrush with plastic crown gears consumes 15 - 20% less energy compared to a similar model with metal gears over a month of regular use. This is because the lower - friction plastic gears require less power from the battery to operate.

Electric Shavers: In electric shavers such as those from Braun, plastic crown gears are utilized in the cutting - head drive mechanism. The lightweight nature of these gears allows the shaver's motor to start up quickly and operate smoothly. The reduced friction also means that the motor doesn't overheat easily, extending the lifespan of the shaver. In a long - term usage test, electric shavers with plastic crown gears had a 25% longer lifespan compared to those with metal gears, mainly due to the reduced stress on the motor caused by the more efficient plastic gears.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology has a deep - seated understanding of plastic crown gears and their role in enhancing mechanical efficiency.

In terms of material innovation, Yigu Technology is constantly exploring new plastic composite materials. By combining different polymers or adding special additives, they can create materials with even better performance. For example, they might blend a small amount of carbon nanotubes into nylon to improve its strength and wear - resistance while maintaining its lightweight nature. This innovative material can further enhance the efficiency of plastic crown gears in high - stress applications.

Customization is another forte of Yigu Technology. They understand that different mechanical systems have unique requirements. For some high - precision medical equipment, they can design plastic crown gears with extremely tight tolerances, ensuring smooth and accurate operation. In industrial automation systems with high - torque demands, Yigu Technology can customize the gear teeth profile and the material thickness of plastic crown gears to handle the heavy loads, thus maximizing the efficiency of the entire mechanical system. Their rich experience in custom - manufacturing plastic metal products enables them to provide tailored solutions that perfectly meet the specific needs of various industries, further demonstrating the superiority of plastic crown gears in enhancing mechanical efficiency.

FAQ

Q1: How do I choose the right plastic material for crown gears in my application?

When choosing the right plastic material for crown gears, consider your application's specific requirements. For applications with high - speed and light - load conditions, such as in small - scale motors for office equipment, materials like polyoxymethylene (POM) are suitable due to their high stiffness, good dimensional stability, and low friction coefficient. If your application involves moderate - load and medium - speed operation, nylon is a great option. It has excellent wear - resistance and self - lubricating properties. For example, in some household appliance gearing systems, nylon crown gears can provide long - term reliable operation. In applications where chemical resistance is crucial, like in the food processing industry, polypropylene can be used, as it can withstand contact with various cleaning agents and food - related substances. Also, take into account the operating temperature. If the gear will be working in a high - temperature environment, materials like PEEK (Polyether - ether - ketone) might be necessary, as it can maintain its mechanical properties at elevated temperatures.

Q2: Can plastic crown gears replace metal ones in all mechanical applications?

Plastic crown gears cannot replace metal ones in all mechanical applications. Plastic crown gears have advantages such as being lightweight, cost - effective, having low noise and good corrosion resistance. In applications with low - load and low - speed requirements, like in small toys or some simple household appliances, plastic crown gears can effectively replace metal gears. However, in high - load applications, such as in heavy - duty industrial machinery or large - scale power transmission systems, metal gears are still preferred. Metal gears have higher strength and can withstand large torque and impact forces without significant deformation or failure. In high - speed applications where high precision is required, plastic gears may not be suitable either. Due to their relatively lower stiffness, plastic gears may experience more vibration and dimensional changes at high speeds, affecting the accuracy of power transmission. Additionally, in extremely high - temperature environments, most plastic materials will soften or even decompose, while metal gears can maintain their structural integrity.

Q3: How can I maintain plastic crown gears to ensure long - term efficiency?

To maintain plastic crown gears for long - term efficiency, regular cleaning is essential. Use a mild cleaning agent and a soft brush to remove any dust, debris, or oil residues that may accumulate on the gear surface. These contaminants can increase friction and cause premature wear. Lubrication is also crucial. Choose a lubricant that is compatible with the plastic material. For example, some silicone - based lubricants work well with most plastic crown gears, reducing friction and wear during operation. Conduct regular inspections to check for any signs of wear, cracks, or deformation. If you notice abnormal noise or vibration during the gear's operation, it may indicate a problem. Replace the gear immediately if significant wear or damage is detected to prevent further damage to the mechanical system. Also, store the plastic crown gears in a dry and cool environment when they are not in use to prevent material degradation due to humidity and temperature changes.