Introduction

In the ever - evolving landscape of mechanical engineering, precision is the name of the game. One innovation that has been making waves in recent years is the development and application of Plastic Bevel Gears. These unassuming components are quietly revolutionizing the way we approach mechanical design, offering a blend of efficiency, cost - effectiveness, and high - tech functionality that is hard to match.

Understanding Plastic Bevel Gears

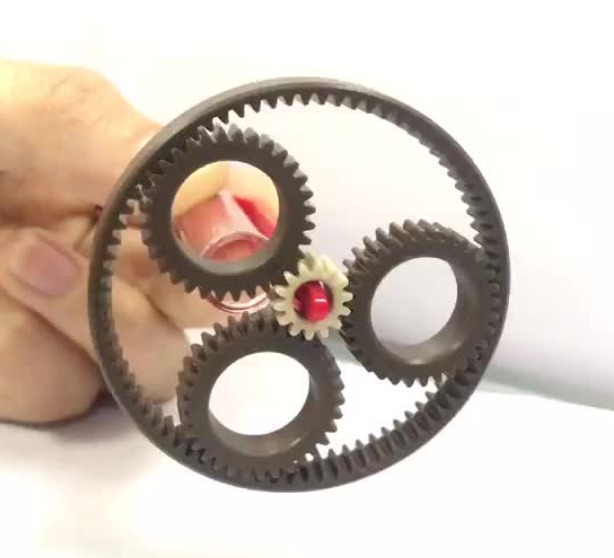

Plastic bevel gears, as the name implies, are a type of gear made from plastic materials and designed with a conical shape. They are part of the bevel gear family, which is used to transmit power between two intersecting shafts, typically at a 90 - degree angle. The basic structure consists of teeth that are cut on the surface of a cone. These teeth can be straight (straight bevel gears) or curved (spiral bevel gears).

The working principle is similar to that of traditional metal bevel gears. When two plastic bevel gears are meshed, the rotation of one gear causes the other to rotate, thereby transferring motion and torque. For example, in a simple hand - operated winch system, plastic bevel gears can be used to change the direction of the force applied by the operator, making it easier to lift heavy objects. The teeth of the driving gear engage with the teeth of the driven gear, and as the driving gear rotates, it pushes the driven gear to rotate in the desired direction.

The Revolution in Precision

What sets plastic bevel gears apart is their ability to offer an unprecedented level of precision. In the past, metal gears were the go - to choice for high - precision applications. However, plastic bevel gears have changed the game. They can be manufactured with extremely tight tolerances, often within a few micrometers. This level of precision ensures smooth operation, reduces vibration, and minimizes wear and tear on the gears themselves and other components in the system.

For instance, in high - end 3C product manufacturing equipment, where precision is crucial for accurate component assembly, plastic bevel gears have found a niche. Their precise movement can ensure that tiny electronic components are placed exactly where they need to be, improving the overall quality and functionality of the final product. This revolution in precision not only enhances the performance of mechanical systems but also opens up new possibilities for design and innovation, which we will explore further in the following sections.

Key Features of Plastic Bevel Gears

Lightweight Design

One of the most prominent features of plastic bevel gears is their lightweight design. Compared to traditional metal bevel gears, plastic bevel gears can be up to 70% lighter. For example, in a portable power - tool application, a metal bevel gear set might weigh 500 grams, while a plastic bevel gear set performing the same function could weigh as little as 150 grams.

This significant reduction in weight has several advantages. Firstly, it enhances the portability of equipment. In the case of handheld power tools or portable medical devices, lighter gears mean the overall device is easier to carry and operate for extended periods. Secondly, it improves energy efficiency. Lighter components require less energy to rotate, which can lead to reduced power consumption in machinery. A study by a leading research institute in mechanical engineering found that replacing metal gears with plastic ones in a small - scale industrial conveyor system reduced energy consumption by 15% over a 12 - month period.

High Precision Manufacturing

Plastic bevel gears are manufactured with high precision. Advanced injection - molding techniques and computer - aided design (CAD) and computer - aided manufacturing (CAM) processes allow for the production of gears with extremely tight tolerances. Tolerances as low as ±0.05mm can be achieved in modern plastic bevel gear manufacturing.

This high - precision manufacturing ensures stable operation. When two plastic bevel gears mesh, the precise alignment of their teeth results in smooth transmission of power. Low - noise operation is another benefit. In applications such as home appliances (e.g., quiet - running blender motors) or office equipment (like printers), the low - noise operation of plastic bevel gears is highly desirable. Moreover, the high precision reduces wear and tear on the gears. A long - term test on a set of plastic bevel gears in a continuous - operation industrial fan showed that after 10,000 hours of operation, the wear on the teeth was minimal, ensuring a long service life for the gears.

Corrosion Resistance

Plastic materials used in plastic bevel gears offer excellent corrosion resistance. Unlike metal gears that can rust and corrode when exposed to moisture, chemicals, or harsh environmental conditions, plastic bevel gears remain unaffected.

For instance, in marine applications, where saltwater can quickly corrode metal components, plastic bevel gears are an ideal choice. A boat's steering mechanism that uses plastic bevel gears can withstand the salty and humid environment without the need for frequent maintenance due to corrosion. In chemical processing plants, where equipment is often exposed to various corrosive chemicals, plastic bevel gears can be used in pumps and mixers. A case study in a chemical factory showed that by replacing metal bevel gears with plastic ones in a chemical - mixing pump, the maintenance frequency was reduced from once every three months to once every two years, saving significant maintenance costs and downtime.

Applications of Plastic Bevel Gears

Automotive Industry

Plastic bevel gears have found their way into several key components in the automotive industry. In the steering system, they play a crucial role. For example, in some electric power - steering systems, plastic bevel gears are used to transmit the rotational motion from the electric motor to the steering column. Their lightweight nature reduces the overall weight of the steering system, which in turn improves fuel efficiency. A study by an automotive research institute showed that replacing metal bevel gears with plastic ones in a mid - sized car's steering system could lead to a 3% increase in fuel efficiency over a long - term driving cycle.

In addition, plastic bevel gears are used in the windshield wiper mechanisms of cars. They enable the smooth and precise movement of the wiper blades, ensuring clear visibility for the driver in various weather conditions. Their corrosion - resistance property is particularly beneficial here, as wiper mechanisms are often exposed to moisture and road salts. The high - precision manufacturing of plastic bevel gears ensures that the wiper blades move in a synchronized and consistent manner, enhancing the overall performance of the wiper system.

Robotics

In the field of robotics, plastic bevel gears are essential components in robot joints and transmission systems. They are used to transfer motion and torque between different parts of the robot, allowing for precise movement. For instance, in a humanoid robot, plastic bevel gears in the knee and elbow joints enable smooth bending and extension. A leading robotics company reported that by using plastic bevel gears in their latest generation of service robots, the precision of the robot's movement increased by 15%, which is crucial for tasks such as picking up and placing objects accurately.

Plastic bevel gears also contribute to the energy - efficiency of robots. Since robots often operate on battery power, the lightweight plastic bevel gears reduce the energy consumption required for movement, thereby extending the battery life. In a quadrupedal robot used for search - and - rescue operations, the use of plastic bevel gears allowed the robot to operate for 20% longer on a single battery charge compared to its previous version with metal gears.

Consumer Electronics

In the world of consumer electronics, plastic bevel gears are used in a variety of small - scale applications. One common use is in the lens - adjustment mechanisms of cameras. Whether it's a DSLR camera or a smartphone camera, plastic bevel gears are used to precisely control the movement of the lens for focusing and zooming. Their high - precision manufacturing ensures that the lens can be adjusted smoothly and accurately, resulting in high - quality images.

For example, in a high - end compact camera, plastic bevel gears enable the smooth transition between wide - angle and telephoto lenses. A camera manufacturer found that by using plastic bevel gears in their lens - adjustment system, they could reduce the noise generated during lens movement by 50%, providing a more pleasant user experience. They are also used in some portable audio devices with adjustable components, such as certain types of headphones with folding mechanisms that use plastic bevel gears for smooth and durable folding and unfolding operations.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology sees great potential in plastic bevel gears. The lightweight, high - precision, and corrosion - resistant features of plastic bevel gears open up vast application prospects in custom - made products.

In the process of custom manufacturing, we can precisely control the material selection and production process according to different customer needs. For example, for products in corrosive environments, we choose high - performance corrosion - resistant plastic materials. Our advanced manufacturing technology and rich experience enable us to produce plastic bevel gears with unique designs and strict tolerances, meeting the diverse requirements of customers in various industries. We are committed to providing high - quality custom plastic bevel gears, helping customers improve product performance and gain a competitive edge in the market.

FAQ about Plastic Bevel Gears

What are the main advantages of plastic bevel gears over metal ones?

Plastic bevel gears are more cost - effective, often costing 30 - 50% less than their metal counterparts in large - scale production. They are significantly lighter, which can reduce the overall weight of a mechanical system by up to 70%. Additionally, plastic bevel gears offer greater design flexibility as they can be easily molded into complex shapes, and they have excellent corrosion resistance, eliminating the need for anti - corrosion treatments.

In which industries are plastic bevel gears most commonly used?

Plastic bevel gears are widely used in the automotive industry, especially in steering systems and windshield wiper mechanisms. In the robotics field, they are crucial for robot joints and transmission systems. They are also commonly found in consumer electronics, such as camera lens - adjustment mechanisms and portable audio device components. Other industries that use them include medical equipment, where their lightweight and corrosion - resistant properties are beneficial, and some home appliances for their low - noise operation.

How to ensure the quality of plastic bevel gears during manufacturing?

Quality assurance in manufacturing plastic bevel gears involves several key factors. First, carefully select the right plastic material according to the application requirements. For example, for high - load applications, materials like polyoxymethylene (POM) or nylon (PA) are often chosen for their high strength and wear resistance. Second, strictly control the injection - molding process parameters, such as injection pressure, injection speed, and cooling time. Close monitoring and adjustment of these parameters can prevent defects like warping, shrinkage, or incomplete filling. Finally, implement a comprehensive quality - inspection system, using tools like 3D scanners and coordinate measuring machines to check the dimensional accuracy of the gears, ensuring they meet the required tolerances.