1. Introduction to Turned Components

In the intricate world of precision parts, turned components stand as the unsung heroes, forming the very foundation of countless mechanical and technological marvels. These components, crafted through the precision machining process of turning, are designed to meet the most exacting standards of accuracy and quality.

Turning is a machining operation where a workpiece rotates while a cutting tool removes material to create a desired shape. This process is capable of producing components with tight tolerances, smooth surfaces, and complex geometries. From the tiniest screws in a wristwatch to the massive shafts in industrial machinery, turned components are everywhere, silently enabling the seamless operation of our modern world.

The importance of turned components cannot be overstated. They are the building blocks that allow industries such as automotive, aerospace, medical, and electronics to push the boundaries of innovation. In the automotive industry, for example, turned components are used in engines, transmissions, and braking systems, where even the slightest deviation from the required specifications can lead to performance issues or safety hazards. In aerospace, these components are crucial for the construction of aircraft engines, landing gear, and avionics systems, where reliability and precision are non - negotiable.

3. Key Aspects of Modern Turned Components

3.1 Material Innovations

The materials used in turned components have evolved significantly over the years. Traditional materials like steel and brass are being complemented, and in some cases replaced, by advanced materials that offer enhanced performance characteristics.

High - strength Alloys: Alloys such as titanium alloys have become increasingly popular in applications where strength - to - weight ratio is crucial. Titanium alloys, for example, offer a strength comparable to many steels but with a much lower density. They also have excellent corrosion resistance, making them ideal for use in marine and aerospace applications. In the aerospace industry, titanium alloy turned components are used in engine components, where they can withstand high temperatures and mechanical stresses while reducing the overall weight of the engine, thereby improving fuel efficiency.

Composite Materials: Carbon - fiber - reinforced polymers (CFRPs) are another class of materials that are making waves in the world of turned components. CFRPs combine the high strength of carbon fibers with the formability of polymers. These materials are extremely lightweight, yet they can have tensile strengths higher than that of steel. In the automotive industry, CFRP turned components are being used in high - performance vehicles to reduce weight, which in turn improves acceleration, braking, and fuel economy. They are also used in racing cars, where every gram of weight reduction can give a competitive edge.

Ceramics: Ceramic materials are finding their way into turned components due to their unique properties. Ceramics have high hardness, excellent wear resistance, and can withstand high temperatures without significant degradation. In the manufacturing of bearings and seals, ceramic turned components can offer much longer service life compared to their metal counterparts. For example, silicon nitride ceramic bearings are used in high - speed machining spindles, where they can operate at speeds up to 100,000 RPM with minimal wear, ensuring high - precision machining operations.

3.2 Precision Manufacturing Techniques

Modern turned components are the result of highly advanced manufacturing techniques that enable the production of parts with micron - level tolerances.

Computer Numerical Control (CNC) Machining: CNC machining has revolutionized the production of turned components. In a CNC turning process, a computer program controls the movement of the cutting tool and the rotation of the workpiece. This level of automation allows for extreme precision. For instance, in the production of medical implants, CNC - turned components can be manufactured with tolerances as tight as ±0.001 mm. The repeatability of CNC machining also ensures that every component produced is identical, which is crucial for mass - production scenarios.

Multi - axis Machining: Traditional turning operations were mainly limited to two - axis machining (X and Z axes in a lathe). However, modern multi - axis machining centers, such as 5 - axis lathes, have expanded the possibilities. With 5 - axis machining, the workpiece can be rotated and tilted in multiple directions while being machined. This allows for the creation of complex geometries in a single setup. For example, in the aerospace industry, 5 - axis CNC turning is used to produce impellers for jet engines. These impellers have intricate blade shapes that would be extremely difficult, if not impossible, to manufacture with traditional 2 - axis turning.

High - speed Machining: High - speed machining (HSM) techniques are being increasingly adopted for the production of turned components. HSM involves using high - speed spindles and specialized cutting tools to remove material at a much faster rate while maintaining high precision. The high cutting speeds can reduce machining time significantly. For example, in the production of aluminum alloy turned components for the electronics industry, HSM can reduce the machining time by up to 50% compared to conventional machining methods, without sacrificing surface finish or dimensional accuracy.

4. Applications Across Industries

Turned components find extensive applications across a wide range of industries, each with its own unique requirements and specifications. The table below provides a comparison of the demand and application characteristics of turned components in different industries:

| Industry | Demand for Turned Components | Application Characteristics |

| Automotive | High - volume demand due to mass production of vehicles. Components need to withstand high mechanical stresses and cyclic loads. | Used in engines (crankshafts, camshafts), transmissions (gears, shafts), and braking systems (brake cylinders, rotors). Precision is crucial for smooth operation and safety. |

| Aerospace | Low - volume but high - value demand. Components must meet the most stringent quality and reliability standards. | Employed in aircraft engines (turbine blades, compressor shafts), landing gear (axles, bushings), and avionics systems (electronic enclosures, connectors). High - temperature and high - strength materials are often required. |

| Medical | Moderate demand with strict quality and biocompatibility requirements. Components need to be highly precise and clean. | Utilized in surgical instruments (scalpels, forceps), implantable devices (hip and knee implants, dental implants), and diagnostic equipment (syringe barrels, sensor housings). Biocompatible materials like titanium and certain polymers are commonly used. |

| Electronics | High - volume demand for miniaturized and high - precision components. Components need to be electrically conductive or insulating depending on the application. | Found in smartphones (screws, antenna components), computers (heat sink fins, hard drive components), and consumer electronics (battery connectors, switches). Materials such as copper, aluminum, and engineering plastics are frequently used. |

4.1 Automotive Industry

In the automotive industry, turned components play a pivotal role in ensuring the optimal performance, safety, and reliability of vehicles. For example, crankshafts, which are critical turned components in engines, convert the reciprocating motion of the pistons into rotational motion. A high - quality crankshaft, manufactured with tight tolerances, can enhance the engine's power output and fuel efficiency. In a typical four - cylinder engine, the crankshaft must be able to withstand thousands of revolutions per minute and high - pressure forces during the combustion process. Any deviation in its dimensions or material properties can lead to engine vibrations, reduced performance, and even engine failure.

Transmission components like gears and shafts are also turned components that are essential for the smooth transfer of power from the engine to the wheels. Precision - made gears ensure quiet operation and efficient power transmission. In modern automatic transmissions, there can be up to 10 or more gears, each with its own unique shape and specifications. These gears are often made from high - strength alloy steels and are heat - treated to improve their wear resistance and toughness.

4.2 Aerospace Sector

The aerospace sector has some of the most demanding requirements for turned components. Aircraft engines operate in extremely harsh environments, with high temperatures, high pressures, and high rotational speeds. Turbine blades, for instance, are turned components that are designed to extract energy from the hot exhaust gases in a jet engine. These blades are typically made from superalloys such as nickel - based alloys, which can withstand temperatures of up to 1,200°C. The manufacturing precision of turbine blades is of utmost importance; even a small defect or deviation in their shape can lead to a significant reduction in engine efficiency and reliability.

Landing gear components, like axles and bushings, must be able to support the entire weight of the aircraft during take - off and landing. These components are made from high - strength steels or titanium alloys to ensure they can handle the heavy loads and impact forces. In addition, they need to be highly reliable, as any failure of the landing gear can have catastrophic consequences.

4.3 Medical Equipment

In the medical field, turned components are used in a variety of applications, from surgical instruments to implantable devices. Surgical instruments, such as scalpels and forceps, require a high level of precision in their manufacturing. Scalpels, for example, need to have a sharp edge that is consistent along its entire length. This is achieved through precision turning and grinding processes. The materials used for these instruments are often stainless steels that are resistant to corrosion and can be easily sterilized.

Implantable devices, like hip and knee implants, must be biocompatible, meaning they do not cause an adverse reaction in the body. These implants are typically made from titanium or titanium alloys, which have excellent biocompatibility and mechanical properties. The surface finish of these implants is also crucial, as a smooth surface can reduce the risk of wear and improve the long - term stability of the implant in the body. Dental implants, another example, are turned components that are inserted into the jawbone to support artificial teeth. These implants need to be precisely shaped to fit the patient's jaw anatomy and provide a stable foundation for the prosthetic teeth.

6. Yigu Technology's Perspective

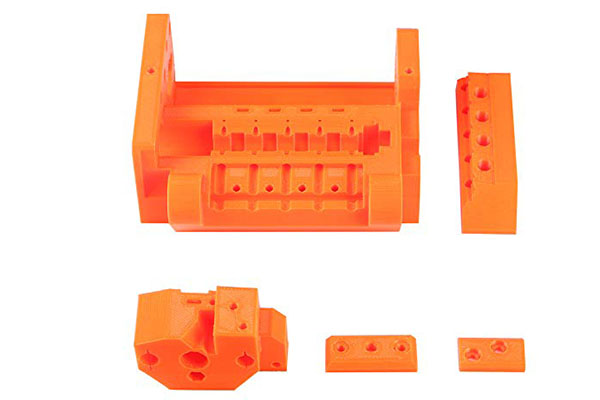

Yigu Technology, as a custom supplier of non - standard plastic and metal products, has rich experience in the manufacturing of turned components. Our state - of - the - art manufacturing facilities are equipped with the latest CNC machining centers and high - speed lathes, enabling us to produce turned components with the highest level of precision.

We understand the importance of material selection in the production of turned components. That's why we work closely with our clients to recommend the most suitable materials based on their specific application requirements. Whether it's a high - strength alloy for an aerospace application or a biocompatible material for a medical device, we have the expertise to ensure the best material - component match.

In terms of the future of turned components, we believe that the trend towards miniaturization and the increasing demand for high - performance materials will continue. We are constantly investing in research and development to stay at the forefront of these trends, and we look forward to collaborating with our clients to develop innovative solutions for the next generation of precision parts.

8. FAQ

8.1 What are the main differences between traditional and modern turned components?

Material: Traditional turned components often rely on basic materials like steel and brass. For example, in old - fashioned machinery, steel was the go - to material for shafts and bushings due to its relatively high strength and low cost. However, modern turned components utilize advanced materials such as titanium alloys, carbon - fiber - reinforced polymers (CFRPs), and ceramics. Titanium alloys, with their high strength - to - weight ratio and excellent corrosion resistance, are now widely used in aerospace applications where weight reduction and durability are crucial.

Process: Traditional turning mainly depended on manual or semi - automated lathes, which had limitations in terms of precision and production speed. Workers had to rely on their skills to control the cutting process, and achieving tight tolerances was challenging. In contrast, modern turned components are produced using advanced CNC machining, multi - axis machining, and high - speed machining techniques. CNC machining allows for extreme precision, with tolerances as tight as ±0.001 mm in some cases, and high - speed machining can reduce production time significantly without sacrificing quality.

Precision: The precision of traditional turned components was relatively low, usually in the range of several tenths of a millimeter. This was sufficient for many basic applications but not for high - tech industries. Modern turned components, on the other hand, can achieve micron - level tolerances, which is essential for applications like medical implants and aerospace components where even the slightest deviation can have severe consequences.

8.2 How does Yigu Technology ensure the quality of turned components?

Yigu Technology ensures the quality of turned components through a multi - faceted approach. First, we source high - quality raw materials from reliable suppliers, and each batch of materials undergoes strict quality inspection before entering the production process. Our state - of - the - art manufacturing facilities are equipped with advanced CNC machining centers and high - speed lathes, which are regularly calibrated to ensure accurate and consistent production.

During the production process, we implement in - line quality control measures. Our experienced technicians use precision measuring instruments such as coordinate measuring machines (CMMs) to monitor the dimensions of the components at various production stages. Additionally, we have a comprehensive quality management system in place that adheres to international standards such as ISO 9001, ensuring that every turned component leaving our factory meets the highest quality requirements.

8.3 What new applications can we expect for turned components in the future?

In the future, turned components are likely to find new applications in emerging fields such as renewable energy and quantum computing. In the renewable energy sector, for example, in advanced wind turbine designs, turned components could be used in the highly precise gearing systems and shafts. These components need to be extremely durable and precise to withstand the continuous mechanical stress and ensure efficient energy conversion.

In the field of quantum computing, turned components may be used in the manufacturing of ultra - precise cooling systems and connection components for quantum processors. The unique requirements of quantum computing, such as extremely low - temperature environments and high - precision electrical connections, call for the development of specialized turned components with unique material properties and manufacturing precision.