In the field of precision manufacturing, the choice of milling manufacturer directly determines the accuracy, cost and market competitiveness of the product. Whether it's auto parts production, aerospace component processing, or medical device research and development, high-quality milling is the core link to ensure product quality. This article will provide you with a systematic milling manufacturer selection guide from key dimensions such as demand determination, qualification evaluation, and cost-value balance to help you avoid selection misunderstandings and find the most suitable partner.

1. Introduction

1.1 Introduce the importance of milling manufacturing

As the core process of precision forming of metal and non-metallic materials, milling is widely used in many high value-added industries. According to industry data, the global precision milling market size will exceed $80 billion in 2024, of which the automotive and aerospace sectors will account for more than 60% of the demand. High-quality milling manufacturing can achieve a machining accuracy of ±0.005mm, which directly ensures the assembly compatibility and service life of the product; On the contrary, insufficient processing accuracy may lead to an increase in product scrap rates and even lead to potential safety hazards. For example, a new energy vehicle company once had abnormal noise problems in batch products due to the substandard accuracy of motor shafts processed by a cooperative milling manufacturer, resulting in direct losses of more than 10 million yuan.

1.2 Challenges in Choosing the Right Milling Manufacturer

The number of milling manufacturers on the market today is large and the qualifications are uneven, which brings many challenges to the selection. On the one hand, small and medium-sized manufacturers mostly focus on low-end processing, lack of high-end equipment and core technology, and are difficult to meet the needs of precision machining; On the other hand, some large manufacturers have high quotations and do not respond to small orders in a timely manner. In addition, there are chaos in the industry such as "shoddy charging" and "false reporting of equipment accuracy", which further increases the difficulty of selection. According to the survey, more than 40% of manufacturing companies have delayed projects or cost overruns due to the wrong selection of milling manufacturers.

2. Determine the needs

2.1 Understand the project requirements

Before selection, it is necessary to clarify the core requirements of the project to avoid blind screening. It is recommended to sort out from the following three dimensions:

- Machining accuracy requirements: Clarify the tolerance range of key dimensions, whether it is ordinary precision (±0.05mm), precision grade (±0.01mm) or ultra-precision grade (±0.001mm);

- Product application scenarios: aerospace, medical and other fields have higher requirements for material purity and processing stability, and ordinary industrial accessories can be appropriately relaxed;

- Special process requirements: Whether special processes such as compound milling and five-axis linkage machining are required.

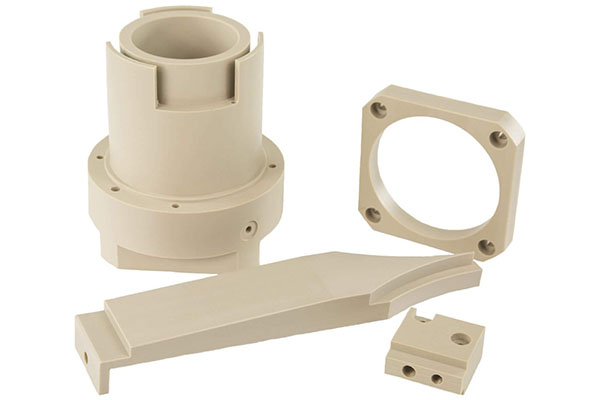

2.2 Determine the material and technical specifications

The milling difficulty and process requirements of different materials vary greatly, and it is necessary to clarify and match the manufacturer's processing capabilities in advance. Here's a comparison of common processing materials with their technical requirements:

| Processing materials | Core technical requirements | Adapted to the type of manufacturer |

|---|---|---|

| Aluminum alloy, plastic | Ordinary milling equipment, focusing on machining efficiency | Small and medium-sized general purpose manufacturers |

| Stainless steel, carbon steel | Carbide tools for stable cutting parameters | A manufacturer with basic precision machining capabilities |

| Titanium alloy, superalloy | Five-axis linkage equipment, professional cooling system | High-end precision manufacturing enterprises |

2.3 Evaluate the scale of production and lead time

Determine the manufacturer's capacity adaptability based on order volume and lead time. small batch trial production (10-100 pieces) can choose small and medium-sized manufacturers with a high degree of flexibility; For mass production (more than 1,000 pieces), it is necessary to pay attention to the number of production lines, automation level and supply chain stability of the manufacturer. For example, an electronic component company needed 5,000 milling parts per month and chose a milling manufacturer with three automated production lines, which not only guaranteed production capacity, but also shortened the delivery cycle from 15 days to 7 days. At the same time, it is necessary to clarify the delivery node and deferred compensation clauses in the contract to reduce risks.

3. Evaluate the manufacturer's qualifications

3.1 Certifications and Standards

Authoritative certification is the basic guarantee of manufacturer strength, and different industries have clear access standards:

- General manufacturing field: ISO 9001 quality management system certification is a basic requirement to ensure the standardization of the production process;

- Aerospace field: AS9100 certification is required, which has stricter requirements for processing accuracy and material traceability;

- Medical field: ISO 13485 certification is required to ensure that products meet medical device safety standards.

In addition, equipment certification also needs to pay attention to the authorized use certificate of high-end milling equipment such as German DMG and Japanese Mazak, which can reflect the manufacturer's machining capabilities.

3.2 Experience and expertise

A manufacturer's industry experience directly impacts problem-solving capabilities. Priority should be given to milling manufacturers that focus on their own industry, for example, companies engaged in aerospace parts processing should choose manufacturers with more than 5 years of experience in milling in the aviation field. An aviation parts company has compared two manufacturers: one has 10 years of aviation milling experience and can quickly solve the deformation problem in titanium alloy processing; Although the other has advanced equipment, it lacks industry experience and fails to meet the standard many times in trial production. At the same time, you can evaluate its professional reserves by asking about the size of the technical team and the years of experience of core engineers.

3.3 Customer testimonials and case studies

Real customer feedback and cases are key to evaluating the credibility of a manufacturer. Information can be obtained in the following ways: first, the manufacturer is required to provide cases in the same industry, focusing on details such as processing difficulty, delivery cycle, and customer satisfaction; second, user reputation is inquired about through industry forums and third-party evaluation platforms; and third, on-site visits to the manufacturer's cooperative customers to understand the actual cooperation experience. For example, a medical device company learned through a visit that a milling manufacturer had the problem of poor batch processing consistency, and avoided cooperation risks in a timely manner.

4. Consider cost and value

4.1 Price structure analysis

The quotation for milling usually includes material costs, processing fees, equipment depreciation, labor costs, etc. The quotation structure of different manufacturers varies greatly, and it needs to be carefully disassembled:

Note: There may be hidden costs in low-price quotations, such as subsequent accuracy correction fees, postponement liquidated damages, etc.; high-price quotations are not necessarily equivalent to high quality, and need to be comprehensively judged based on equipment level and process capabilities.

It is recommended to inquire from 3-5 manufacturers, establish a quotation comparison table, clarify the cost proportion of each part, and avoid being misled by unreasonable quotations.

4.2 Balance between cost and quality

The core of selection is to achieve a balance between cost and quality, rather than simply pursuing low or high prices. For example, ordinary industrial accessories can choose cost-effective manufacturers to control costs; while core precision components need to prioritize quality and appropriately increase the budget. According to statistics, choosing a manufacturer with standard quality but moderate price can reduce the overall cost of products by 15%-20%. At the same time, you can negotiate with manufacturers to reduce the unit price by optimizing order batches and extending cooperation cycles.

4.3 Potential benefits of long-term cooperation

Establishing long-term cooperation with high-quality milling manufacturers can bring many benefits: first, obtain more favorable quotations and reduce long-term procurement costs; second, manufacturers better understand the needs of enterprises, improve processing efficiency and product consistency; third, obtain support in technology research and development and process optimization to help product upgrades. For example, an auto parts company has long-term cooperation with a milling manufacturer, and the manufacturer has optimized the processing process in a targeted manner, reducing the product scrap rate from 3% to 0.5%, saving more than 2 million yuan per year.

5. Conclusion

Choosing the right milling manufacturer is a systematic process that requires a comprehensive evaluation of the manufacturer's qualifications, experience, and cost value based on clear needs, and ultimately achieve supply and demand matching. High-quality partners can not only ensure product quality and delivery efficiency, but also provide technical support for the long-term development of enterprises. In the selection process, do not rush for success, multi-dimensional research, comparison, and trial production verification when necessary to ensure that the selected manufacturer truly meets its own development needs.

【Yigu Technology's view】The core competitiveness of milling manufacturing lies in precision and stability, and when choosing a manufacturer, you should jump out of the misunderstanding of "price only" and take technical strength and industry adaptability as the core consideration. Yigu Technology has been deeply involved in the field of precision manufacturing for many years and understands the importance of high-quality milling manufacturers to the development of enterprises. It is recommended that enterprises focus on long-term value when selecting models, and cooperate deeply with manufacturers with innovative capabilities and strict quality control to jointly cope with the challenges brought about by market competition and technological change.

FAQ

Q: How to quickly judge whether the machining accuracy of the milling manufacturer is up to standard? A: You can ask the manufacturer to provide a sample test report, focusing on the tolerance fluctuation range of key dimensions; At the same time, the accuracy level and use status of its testing equipment (such as coordinate measuring instrument) are inspected on the spot, and if necessary, a third-party organization is entrusted to conduct sample testing.

Q: How to choose a milling manufacturer for small batch orders? A: Give priority to small and medium-sized manufacturers with strong flexible production capacity and fast response to small batch orders, which usually have more advantages in trial production and customized processing; At the same time, pay attention to its minimum order quantity requirements and trial production cycle to avoid unnecessary cost waste.

Q: How do you ensure the lead time when working with a milling manufacturer? A: Specify the delivery node, batch delivery plan and deferred compensation terms in the contract; Regularly communicate with manufacturers about production progress and reserve buffer time in advance; For key orders, special personnel can be arranged to follow up on production.