Introduction

In recent years, 3D printing has been making waves in various industries, and the jewelry casting field is no exception. This innovative technology has gradually emerged as a game - changer, revolutionizing the way jewelry is designed and produced. But what exactly is 3D printing for jewelry casting, and how does it work? What are its advantages over traditional methods, and what challenges does it face? These are the questions that many jewelry designers, manufacturers, and enthusiasts are eager to have answered.

This article aims to comprehensively analyze 3D printing in jewelry casting. By exploring its working principles, different types of 3D printing technologies applicable to jewelry, materials used, design considerations, and cost - effectiveness, we hope to help you gain a deep understanding of this technology. Whether you are a professional in the jewelry industry looking to upgrade your production methods or a jewelry lover interested in the latest manufacturing trends, the following content will provide you with valuable insights and help you solve related problems you may encounter.

How Does 3D Printing Work in Jewelry Casting?

The Basic Principle

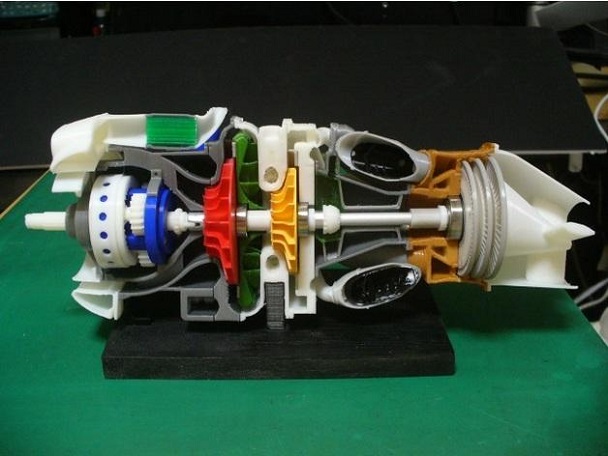

3D printing, at its core, is an additive manufacturing process. It builds objects layer by layer from a digital model. In the context of jewelry casting, the journey begins with a digital design created using Computer - Aided Design (CAD) software. Designers can create highly detailed and complex 3D models of jewelry pieces, whether it's a simple pendant or an elaborate ring with intricate patterns.

Once the digital model is complete, the 3D printer slices this model into extremely thin cross - sectional layers. Each layer is like a 2D slice of the final 3D object. The printer then deposits or solidifies materials layer by layer according to the shape defined by these slices. This process continues until all the layers are stacked up, forming the complete three - dimensional jewelry object.

The Specific Process for Jewelry

- Digital Model Design: Designers use specialized CAD software, such as Rhinoceros 3D, MatrixGold, or JewelCAD. These tools allow for the creation of highly detailed jewelry models. For example, a designer might create a ring with a unique, organic - shaped band and a detailed gem - setting design. They can precisely define the dimensions, curves, and any intricate details, like filigree patterns or micro - engraving.

- 3D Printing Technology Selection:

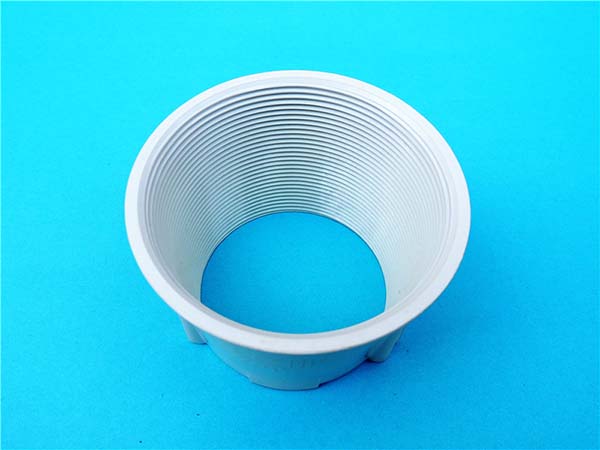

- Stereolithography (SLA): This is a popular choice for jewelry casting. SLA uses a laser to cure a liquid photopolymer resin layer by layer. It offers high precision, with layer thicknesses as small as 25 - 100 microns. This makes it suitable for creating detailed wax - like resin models that can be used directly in the lost - wax casting process. For instance, a delicate lace - like pendant design can be accurately reproduced with SLA.

- Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered materials, such as nylon or metal powders. In jewelry casting, it can be used to create durable and accurate patterns. Nylon SLS models can be used as sacrificial patterns in investment casting, and metal SLS can directly produce metal jewelry components. For example, creating a high - strength metal bracelet with a complex geometric structure.

- Printing the Model: After choosing the technology, the digital model is sent to the 3D printer. The printer follows the instructions to build the model. For wax or resin models, they are printed with supports in place to ensure the integrity of overhanging and complex parts during the printing process.

- Post - Printing Processing: Once the model is printed, the supports are removed. For resin models, they may need to be further cured under UV light to ensure full hardening. The model is then cleaned to remove any remaining debris or uncured resin.

- Lost - Wax Casting (the Most Common Subsequent Process): The printed wax or resin model is used in the lost - wax casting process. The model is first invested in a ceramic or plaster mold. Then, the mold is heated, and the wax/resin model is melted and drained out (hence the name "lost - wax"). Molten metal, such as gold, silver, or platinum, is then poured into the empty mold cavity. After the metal cools and solidifies, the mold is broken away, revealing the metal jewelry piece, which can then be further polished, set with gemstones, and finished.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology believes that 3D printing has brought unprecedented innovation opportunities to jewelry casting. This technology enables us to create jewelry with complex structures and personalized designs that were previously difficult to achieve, which can better meet the diverse needs of customers. We are constantly exploring the application of 3D printing technology in jewelry casting, aiming to provide more high - quality and unique products and services to our clients, and contribute to the development of the jewelry industry.

FAQ

What are the best 3D printing materials for jewelry casting?

- Wax Materials: Wax is a classic choice for 3D printing in jewelry casting, especially for the lost - wax casting process. It has a low melting point, which is ideal for being melted out of the mold during casting. For example, paraffin - based waxes can be printed with high precision, creating smooth surfaces and detailed features. They are suitable for creating wax patterns that closely mimic the final jewelry design, and are often used for traditional - style jewelry with intricate filigree work.

- Resin Materials: Photopolymer resins are widely used in SLA 3D printing for jewelry. These resins can achieve extremely fine details, with some capable of printing features as small as 0.1 mm. They come in different formulations, some with a wax - like appearance and texture, which are perfect for directly replacing wax patterns in lost - wax casting. Resins are great for modern, detailed jewelry designs, such as geometric - shaped rings or pendants with micro - scale patterns.

- Metal Materials: Metal powders, like gold, silver, and platinum alloy powders, can be used in metal 3D printing technologies such as Selective Laser Melting (SLM). This allows for the direct production of metal jewelry without the need for a separate casting step. Metal 3D - printed jewelry has excellent strength and durability. For instance, a high - end, one - of - a - kind platinum ring with a complex internal structure can be directly printed using SLM technology.

How accurate is 3D - printed jewelry?

The accuracy of 3D - printed jewelry can be quite high, often reaching the millimeter or even sub - millimeter level. For example, SLA 3D printers commonly used in jewelry production can achieve layer thicknesses as small as 25 - 100 microns. In a well - calibrated SLA system, the dimensional accuracy of the printed model can be within ±0.1 mm for small - scale jewelry pieces. However, the accuracy can be affected by several factors:

- Printing Technology: Different 3D printing technologies have varying levels of accuracy. SLA and Digital Light Processing (DLP) generally offer higher precision compared to Fused Deposition Modeling (FDM). FDM, which extrudes melted plastic filaments, may have a layer height of 0.1 - 0.4 mm, resulting in a relatively rougher surface and lower accuracy for fine jewelry details.

- Printer Calibration: A poorly calibrated 3D printer can lead to inaccuracies. If the printer's axes are not properly aligned, the printed model may be distorted. For example, a misaligned X - axis could cause a ring to be elliptical instead of circular.

- Model Design: Complex models with thin walls or overhanging structures may experience some degree of warping or deviation during printing, which can affect the final accuracy. For instance, a pendant with very thin, delicate chains may not print as perfectly as a solid - bodied ring.

Can 3D printing replace traditional jewelry casting methods completely?

3D printing has many advantages in jewelry casting, such as enabling highly complex and customized designs, reducing material waste, and shortening the production cycle for one - of - a - kind pieces. However, it is unlikely to completely replace traditional jewelry casting methods in the near future:

- Advantages of Traditional Methods: Traditional casting methods, like the lost - wax casting that has been used for centuries, are still highly efficient and cost - effective for mass - producing simple jewelry designs. For example, producing a large quantity of basic wedding bands or simple stud earrings. The molds can be reused multiple times, and the overall production process is well - established and understood, with a large pool of skilled artisans.

- Limitations of 3D Printing: Although 3D printing technology has advanced significantly, the equipment and materials can still be relatively expensive. Printing large - scale production runs can be time - consuming, and post - processing, such as removing supports and surface finishing, can add to the overall cost. Additionally, some traditional jewelry manufacturers may be hesitant to invest in new 3D printing technology due to the need for retraining their workforce.