What is SLA Resin Printing?

SLA resin printing, short for Stereolithography Apparatus resin printing, is a widely - used and revolutionary 3D printing technology. It belongs to the category of vat photopolymerization 3D printing methods.

The basic principle of SLA resin printing is fascinating. It uses a light - source, usually a laser, to selectively cure layers of liquid photopolymer resin. When the ultraviolet (UV) light from the laser hits the resin, a photochemical reaction occurs. The resin molecules link together, transforming from a liquid state into a solid state. This process starts from the bottom layer of the build platform. As each layer is cured, the build platform gradually lowers, and a new layer of resin is spread on top. The laser then cures the next layer according to the 3D model's cross - sectional data, and this process repeats layer by layer. Eventually, a three - dimensional object is formed. For example, imagine creating a small statue. First, the SLA printer will create the base layer of the statue's feet by curing the resin in the exact shape of the cross - section at that height. Then, as the build platform moves down, layer after layer of the legs, torso, arms, and head are cured, gradually bringing the statue to life.

How Does SLA Resin Printing Work?

The Basic Principle

SLA resin printing operates based on a photopolymerization process. As mentioned before, the core is the use of light energy. A high - precision light source, such as a high - power ultraviolet laser, is crucial. The 3D model that needs to be printed is first sliced into numerous thin layers by specialized software. Each layer has a specific cross - sectional shape.

When the printing process starts, the light source projects onto the liquid resin in the resin tank. The resin is a special photopolymer material. When the ultraviolet light hits the resin, photons in the light are absorbed by photo - initiators in the resin. These photo - initiators then decompose into highly reactive free radicals. These free radicals react with the monomer molecules in the resin, causing them to polymerize and cross - link, thus transforming the liquid resin into a solid state. This solidification occurs layer by layer according to the cross - sectional data of the 3D model.

Key Components Involved

- Light Source: The light source is the “engine” of the SLA resin printing process. Lasers are commonly used due to their high energy density and precision. For example, a 405 - nm wavelength ultraviolet laser is very popular in SLA printers. This specific wavelength can be effectively absorbed by the photo - initiators in the resin, triggering the photopolymerization reaction accurately. High - power lasers can speed up the curing process, reducing the overall printing time.

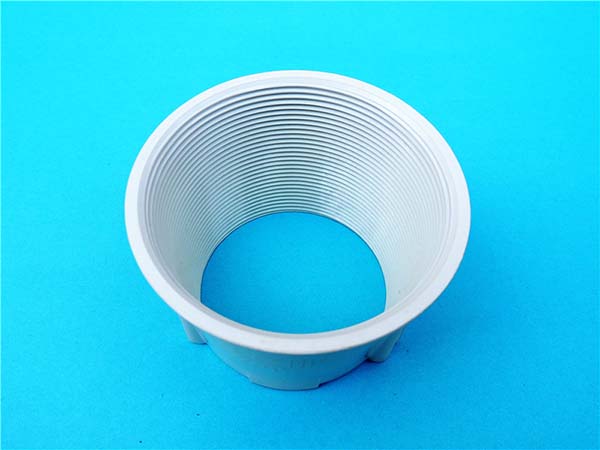

- Resin Tank: This is where the liquid resin is stored. It is usually made of a light - transmissive material, such as a special type of plastic, which allows the ultraviolet light from the light source to pass through and reach the resin. The resin tank needs to be carefully designed to ensure a smooth flow of resin and prevent air bubbles from being trapped, as air bubbles can cause defects in the printed object.

- Build Platform (Lift Mechanism): The build platform is where the printed object is formed. It starts at the top - most position of the resin tank. As each layer of resin is cured, the build platform slowly descends into the resin tank at a precisely controlled speed. This downward movement allows a new layer of resin to flow over the previously cured layer, preparing for the next curing process. The lift mechanism that controls the movement of the build platform must be highly accurate. For instance, an error of even a fraction of a millimeter in the movement can lead to misalignment between layers and affect the quality of the final printed product.

How Does SLA Resin Printing Compare with Other Printing Methods?

When it comes to 3D printing, different methods have their own characteristics. Here is a comparison between SLA resin printing and other common 3D printing methods, such as Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS):

| Comparison Items | SLA Resin Printing | FDM | SLS |

| Precision | High, can achieve micron - level precision, often as low as 0.025mm | Relatively low, with a general precision of 0.1 - 0.4mm | Moderate, usually within 0.1 - 0.2mm |

| Speed | Fast in terms of layer - by - layer curing, but the overall time is also affected by the complexity of the model | Generally slow as the nozzle needs to extrude material layer by layer | Slower due to the sintering process of powder materials |

| Cost | High equipment cost, and the resin materials are relatively expensive. However, it can be cost - effective for small - batch, high - precision production | Low equipment cost, and the filament materials are relatively cheap. Suitable for low - cost, large - scale production | High equipment cost, and the powder materials are also costly. High - cost for both equipment and materials |

| Applicable Materials | Mainly photopolymer resins, which can be customized with different properties such as hardness, flexibility, and transparency | A variety of thermoplastics like ABS, PLA, PETG, etc. | Metal powders, ceramic powders, polymer powders, etc. |

| Surface Quality | Smooth surface, suitable for products with high - surface - finish requirements | Rough surface, often requires post - processing such as sanding and polishing | Surface is relatively rough, also needs post - processing |

From the above comparison, we can see that SLA resin printing stands out in terms of precision and surface quality, making it an ideal choice for applications that demand high - accuracy and smooth - surface products, such as jewelry design, dental models, and high - end prototypes.

Yigu Technology's View

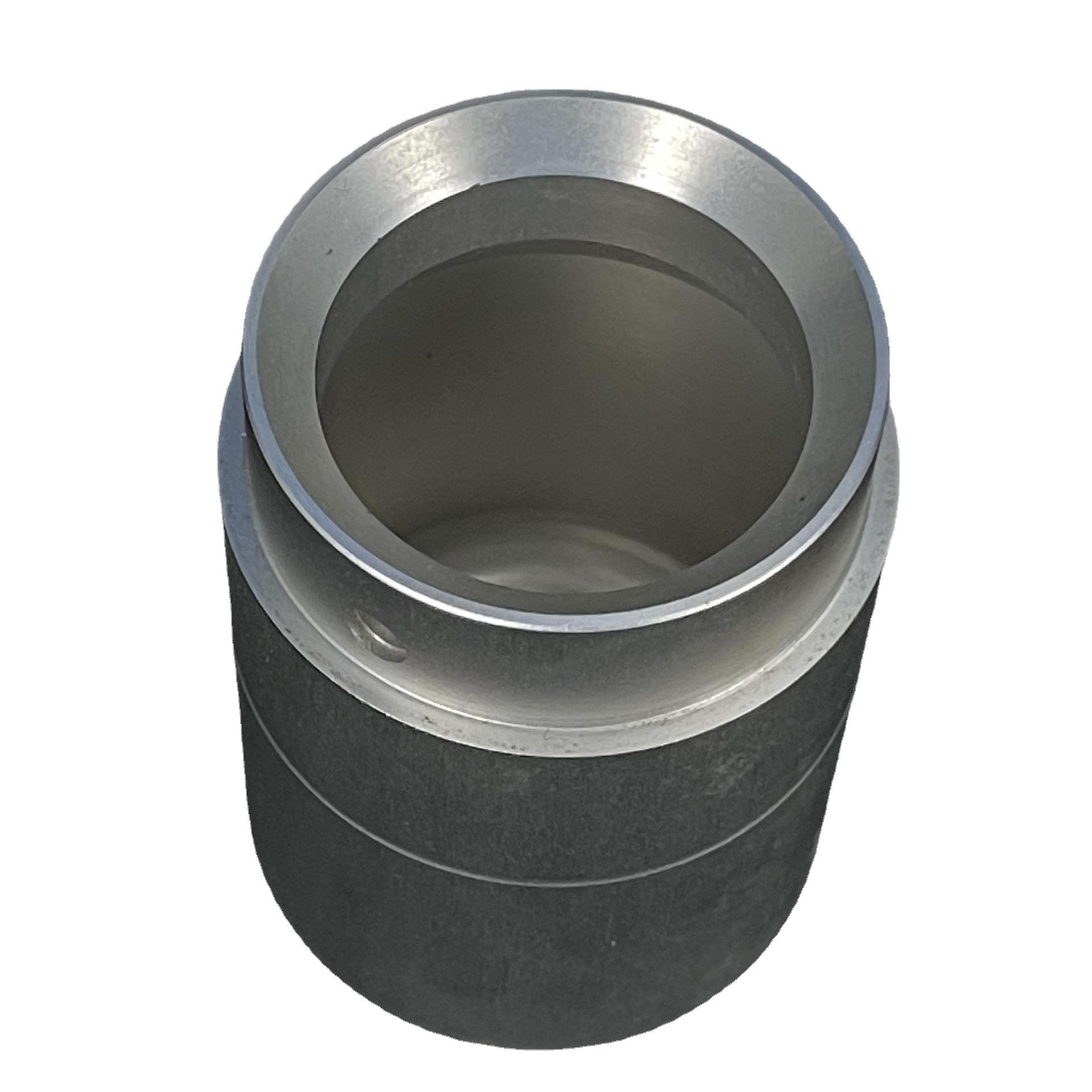

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the impact of SLA resin printing on the industry. SLA resin printing can meet the needs of small - batch customization perfectly. In the product research and development stage, it enables us to quickly produce prototypes. For example, when developing a new non - standard plastic part, we can use SLA resin printing to make a prototype within a few days. This significantly shortens the development cycle and improves the R & D efficiency, allowing our customers to get their products to market faster.

With years of experience and strong technical strength in this field, Yigu Technology can undertake various complex SLA resin printing projects. Our professional team is proficient in operating SLA printers and dealing with different types of resin materials. We are committed to providing high - quality customized products to meet the diverse needs of our customers.

FAQ

What types of resins are best for SLA printing?

There are several types of resins suitable for SLA printing, each with its own unique properties and applications. General - purpose resins are the most commonly used. They offer a good balance of properties, such as moderate hardness, decent mechanical strength, and are suitable for a wide range of applications like general prototypes, small - scale figurines, and educational models. For example, they can be used to create simple product prototypes for initial design verification. High - temperature resins are designed to withstand elevated temperatures. They are ideal for applications where the printed parts will be exposed to heat, such as in automotive engine components prototypes or some industrial equipment parts. These resins can maintain their shape and mechanical properties even at high temperatures, usually up to 150 - 250°C depending on the specific resin type. Tough or flexible resins are perfect for applications that require flexibility or high impact resistance. They can be used to print items like flexible joints, rubber - like products, or parts that need to withstand bending or stretching forces, such as wearable devices components or some sports equipment prototypes.

How can I improve the surface quality of SLA printed parts?

To enhance the surface quality of SLA printed parts, there are several effective methods. Optimizing print parameters is crucial. For instance, reducing the layer thickness can lead to a smoother surface. A thinner layer (e.g., 0.025mm instead of 0.05mm) means more layers are used to build the object, resulting in a more gradual transition between layers and a smoother overall surface. Adjusting the exposure time of the light source also plays a role. An appropriate exposure time ensures that the resin is fully cured without over - curing, which can cause surface roughness. Selecting the right post - processing methods is another key factor. Chemical polishing, where the printed part is immersed in a chemical solution (such as isopropyl alcohol for some resins), can dissolve the small surface imperfections and create a smooth finish. Sanding, especially with fine - grit sandpaper (e.g., 1000 - 2000 grit), can also be used to gradually smooth the surface before applying a final polish. Using high - quality resins is essential. High - purity resins with consistent viscosity and polymerization properties are less likely to cause surface defects during the printing process.

Is SLA resin printing suitable for large - scale production?

SLA resin printing has certain limitations when it comes to large - scale production. On the one hand, the high cost is a major drawback. The equipment itself is relatively expensive, and the cost of resin materials is also high compared to some other 3D printing materials like FDM filaments. For example, a professional - grade SLA printer can cost thousands of dollars, and the resin can cost tens of dollars per liter. Moreover, the resin has a limited shelf - life, which adds to the overall cost in large - scale production. On the other hand, the printing speed may not be sufficient for large - scale production requirements. Although the layer - by - layer curing process is relatively fast in SLA, the overall time for printing large numbers of complex parts can still be long. However, for small - batch, high - precision production, SLA resin printing shines. It can produce parts with micron - level precision, which is difficult to achieve with other methods at a reasonable cost. So, in general, SLA resin printing is more suitable for small - batch, high - precision production rather than large - scale mass production.