1. Introduction

In the rapidly evolving landscape of modern manufacturing, the 3D printed carbon fiber mold has emerged as a game - changer. Carbon fiber, renowned for its high strength - to - weight ratio, stiffness, and excellent thermal and chemical resistance, when combined with the innovative 3D printing technology, opens up a world of possibilities across multiple industries.

These molds play a crucial role in industries such as aerospace, automotive, and marine. In aerospace, where every ounce of weight reduction can translate into significant fuel savings and enhanced performance, 3D printed carbon fiber molds are used to create lightweight yet incredibly strong components. For example, parts of aircraft wings and fuselages can be produced with high precision using these molds, ensuring a perfect fit and optimal aerodynamics.

In the automotive industry, 3D printed carbon fiber molds enable the production of high - performance components like carbon fiber body panels and engine parts. They allow for faster prototyping, reducing the time from concept to production. This not only speeds up the development process but also helps manufacturers stay competitive in a market with ever - changing demands.

The marine industry also benefits from these molds. The corrosion - resistant nature of carbon fiber makes it an ideal material for boat hulls and other marine components. 3D printed carbon fiber molds ensure that these components can be produced with complex geometries, enhancing the performance and durability of watercraft.

Given their importance, it's essential to understand various aspects of 3D printed carbon fiber molds, including their materials, manufacturing process, advantages, and challenges. In the following sections, we will delve deeper into these areas to provide a comprehensive overview for manufacturers, engineers, and anyone interested in this cutting - edge technology.

2. What is a 3D Printed Carbon Fiber Mold?

2.1 Definition and Basics

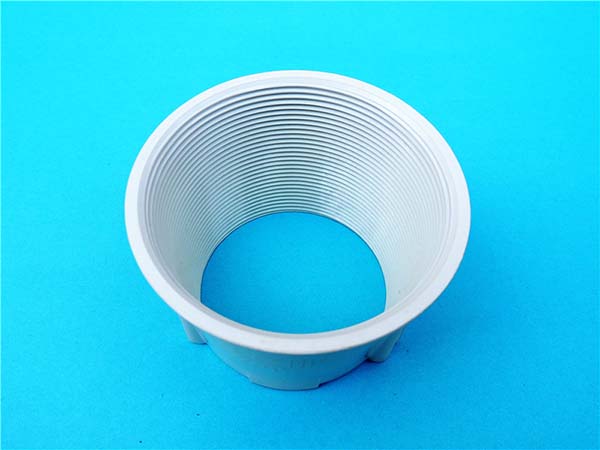

A 3D printed carbon fiber mold is a specialized tool created through additive manufacturing techniques, using carbon fiber - reinforced materials. 3D printing, also known as additive manufacturing, builds objects layer by layer based on a digital 3D model. In the case of carbon fiber molds, the process starts with a detailed 3D design. This design is then sliced into thin cross - sectional layers by specialized software.

The basic principle involves extruding or depositing a mixture of carbon fiber filaments and a binding matrix, typically a thermoplastic resin such as ABS (Acrylonitrile Butadiene Styrene) or PLA (Polylactic Acid). As each layer is laid down, it adheres to the previous one, gradually building up the three - dimensional shape of the mold. Carbon fiber, with its high strength - to - weight ratio, provides the mold with exceptional mechanical properties. It can withstand high pressures and temperatures during the molding process, making it suitable for manufacturing parts that require high precision and durability.

2.2 Key Components of 3D Printed Carbon Fiber Molds

- Carbon Fiber Material: Carbon fiber is the star component. It is made up of thin, strong filaments composed mainly of carbon atoms. These filaments are incredibly lightweight yet have a tensile strength several times that of steel. For example, a high - modulus carbon fiber can have a tensile strength of over 5000 MPa, while steel typically has a tensile strength in the range of 200 - 2000 MPa. The carbon fiber filaments are often pre - impregnated (pre - preg) with a resin matrix. This pre - preg material makes it easier to handle during the 3D printing process and ensures a uniform distribution of the resin, which is crucial for the structural integrity of the mold.

- Printed Structure: The 3D printed structure of the mold is designed with specific geometric features to meet the requirements of the molding process. Complex internal channels can be printed for cooling purposes. These channels allow for the circulation of a coolant, such as water or a specialized heat - transfer fluid. By effectively dissipating heat during the molding process, the cooling channels help to prevent warping and ensure consistent part quality. Additionally, the outer shape of the mold is precisely printed to match the negative of the part to be produced. This high - precision printing enables the production of parts with intricate details and tight tolerances, which is especially important in industries like aerospace and automotive.

3. Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the 3D printed carbon fiber mold. In our custom - manufacturing business, these molds hold great application prospects. The high precision and complex - geometry - printing capabilities of 3D printed carbon fiber molds enable us to produce unique non - standard products that meet the diverse needs of our clients.

The excellent mechanical properties of carbon fiber enhance the durability and quality of the molds, leading to better - quality end - products. They also reduce the production time for custom prototypes, allowing us to quickly turn around samples for client approval. This technology not only improves our production efficiency but also gives us a competitive edge in the market, making it an essential part of our manufacturing process for delivering high - value custom solutions.

4. FAQ

4.1 What materials are commonly used in 3D printed carbon fiber molds?

Commonly used materials in 3D printed carbon fiber molds include carbon fiber - reinforced thermoplastics such as carbon fiber - filled ABS, PLA, and Nylon. Carbon fiber filaments are often pre - impregnated with a resin matrix, which could be epoxy resin in many cases. These materials offer high strength - to - weight ratios. For example, carbon fiber - filled Nylon can have a tensile strength increase of up to 300% compared to pure Nylon, making it suitable for molds that need to withstand significant mechanical stress during the molding process.

4.2 How accurate are 3D printed carbon fiber molds?

The accuracy of 3D printed carbon fiber molds depends on several factors, including the 3D printing equipment and the printing process used. Generally, high - end industrial 3D printers can achieve an accuracy of ±0.1 - 0.2 mm for larger molds, while for smaller and more intricate molds, the accuracy can be as high as ±0.05 mm. However, factors like material shrinkage during the curing process and the complexity of the mold design can also affect the final accuracy. For instance, complex internal geometries with thin walls may experience more significant dimensional changes, potentially reducing the overall accuracy slightly.

4.3 Can 3D printed carbon fiber molds be used for mass production?

3D printed carbon fiber molds can be used for mass production, but there are some considerations. In terms of production efficiency, 3D printing is generally slower compared to traditional mold - making methods like injection molding for large - scale production. However, the high strength and durability of 3D printed carbon fiber molds can reduce the need for frequent mold replacements. In terms of cost, the initial investment in 3D printing equipment and carbon fiber materials can be high. But for small - to - medium - scale mass production runs, especially when dealing with complex mold designs, 3D printed carbon fiber molds can be cost - effective as they eliminate the need for expensive custom tooling in traditional manufacturing. For example, if a company needs to produce 1000 - 5000 units of a complex - shaped component, 3D printed carbon fiber molds could be a viable option.