Introduction to Metal Additive Manufacturing

Metal Additive Manufacturing (MAM), also known as metal 3D printing, is a revolutionary technology that is transforming industries such as aerospace, automotive, medical, and tooling. MAM uses advanced techniques to build metal parts layer by layer, directly from digital files. Unlike traditional manufacturing processes, which often require extensive machining or assembly, MAM allows for the production of complex, customized, and highly efficient components. This technology is poised to reshape manufacturing by improving design flexibility, material efficiency, and production speed.

Principles and Techniques of Metal Additive Manufacturing

Metal Additive Manufacturing involves several techniques to create intricate parts using metal powders or wire:

1. Selective Laser Melting (SLM)

SLM uses a laser to melt metal powder, layer by layer, to form a solid structure. It allows for the production of high-precision, complex geometries with excellent material properties.

2. Electron Beam Melting (EBM)

In EBM, an electron beam is used to melt metal powder in a vacuum. This technique is commonly used for materials like titanium and cobalt-chromium alloys, offering excellent mechanical properties for demanding applications.

3. Direct Metal Deposition (DMD)

DMD uses a laser or electron beam to melt metal wire or powder, which is then deposited onto a substrate to form the desired shape. This process is ideal for repairing or adding material to existing parts.

Each technique in MAM enables the production of parts that would be difficult or impossible to achieve with traditional methods, especially for intricate internal features and complex geometries.

Comparison with Traditional Manufacturing

Advantages Over Traditional Methods

- Design Freedom

- MAM allows for the creation of complex shapes and internal structures that are difficult to produce with traditional methods, such as CNC machining or casting.

- Material Efficiency

- MAM minimizes waste by building parts layer by layer, unlike subtractive methods that waste material by cutting away excess.

- Rapid Prototyping

- MAM speeds up the design and prototyping phases, reducing time-to-market significantly.

- Customization

- MAM enables the production of customized parts, tailored to specific needs, without the requirement for expensive molds or tooling.

- Reduced Assembly

- Complex parts can be printed as a single unit, reducing the need for multiple components and assembly processes.

Disadvantages of Traditional Methods

- Limited Design Flexibility

- Traditional methods are often constrained by the limitations of molds, tools, and machining processes, which restrict design possibilities.

- Material Waste

- Subtractive processes, such as CNC machining, often produce significant material waste.

- Longer Development Cycles

- Creating and refining prototypes through traditional methods takes longer and is more costly.

- High Tooling Costs

- The production of molds and dies can be expensive and time-consuming in conventional manufacturing.

Advantages of Metal Additive Manufacturing

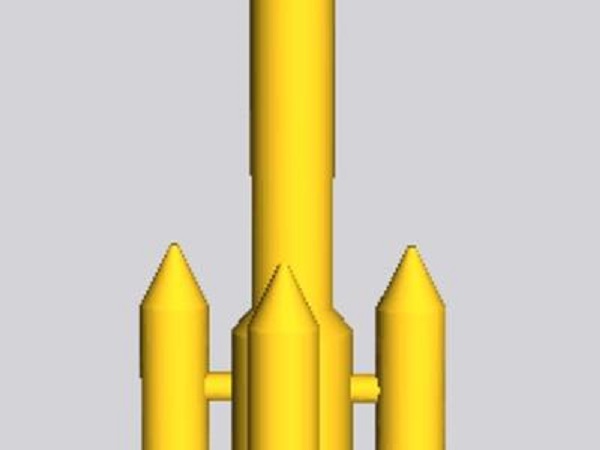

1. Design Freedom and Complexity

MAM allows for the production of intricate and optimized designs that improve performance while reducing weight. Parts with complex internal channels, lattice structures, and other advanced features can be manufactured without the constraints of traditional methods.

2. Material Efficiency and Cost Savings

MAM reduces material waste by using only the required amount of material to build parts layer by layer. This efficiency translates into cost savings, as well as environmental benefits due to reduced waste and energy consumption.

3. Rapid Prototyping and Faster Time-to-Market

MAM accelerates prototyping by quickly producing functional parts, enabling faster iterations. This significantly reduces development cycles and helps businesses bring products to market more quickly, a major advantage in competitive industries.

Applications of Metal Additive Manufacturing

Aerospace and Defense

- Lightweight Components: MAM is used to create lightweight, high-performance parts for aerospace, such as engine components and structural parts. This reduces overall weight and improves fuel efficiency.

- Customization and Prototyping: MAM allows for quick prototyping of custom parts, enhancing flexibility and reducing lead times in the aerospace and defense sectors.

Automotive Industry

- Lightweighting: MAM produces lightweight parts that help improve vehicle fuel efficiency and overall performance.

- Customization and Low-Volume Production: MAM is ideal for creating custom parts or small production runs, such as brackets or exhaust systems, which are commonly required in luxury or performance vehicles.

- Rapid Prototyping: Automotive manufacturers use MAM to speed up the design and testing process, allowing faster time-to-market for new vehicle models.

Medical and Dental Implants

- Patient-Specific Implants: MAM enables the creation of custom implants and prosthetics tailored to an individual’s anatomy, offering better outcomes and faster recovery times.

- High Precision: MAM is used to create highly precise dental products like crowns, bridges, and other prosthetics, ensuring both functionality and aesthetic quality.

Tooling and Mold Making

- Faster Tooling Production: MAM accelerates the production of high-quality molds and dies, which traditionally require significant machining time and costs.

- Improved Flexibility: MAM enables quick modifications to molds and tooling designs, which is crucial in industries with frequent changes in production requirements.

FAQs

What are the main benefits of metal additive manufacturing over traditional manufacturing methods?

Metal Additive Manufacturing provides benefits such as:

- Greater design flexibility, enabling the production of complex parts.

- Reduced material waste, which lowers costs and environmental impact.

- Faster prototyping, leading to shorter development cycles and quicker market entry.

- Customization without the need for expensive tooling, making it ideal for unique or low-volume production.

How does metal additive manufacturing impact the aerospace and automotive industries?

- Aerospace: MAM allows the production of lightweight, high-performance parts that reduce weight and improve fuel efficiency. It also enables rapid prototyping and customization of components for unique needs.

- Automotive: MAM produces lightweight parts that enhance vehicle performance and fuel efficiency. It also enables the rapid prototyping of components, reducing the time it takes to develop new vehicle models.

Can metal additive manufacturing be used for medical and dental applications?

Yes, MAM is widely used in the medical field for creating patient-specific implants, prosthetics, and surgical instruments. The ability to create precise, customized parts ensures better fitting and faster recovery times. In dentistry, MAM is used to produce high-precision crowns, bridges, and other prosthetics with excellent aesthetic results.

Conclusion

Metal Additive Manufacturing is a game-changer for the manufacturing industry. Its ability to produce complex, customized, and high-performance parts with minimal material waste and rapid prototyping capabilities is revolutionizing sectors like aerospace, automotive, medical, and tooling. As the technology continues to evolve, it will play an even greater role in shaping the future of manufacturing, enabling greater design freedom, efficiency, and innovation across industries.