1. Basic concept and classification of machining center: how to choose different scenarios?

As the core equipment of intelligent manufacturing, the classification of machining centers directly determines production efficiency and processing accuracy. Among the common types, vertical machining centers are suitable for vertical machining of small and medium-sized parts, accounting for more than 60% of the market share, and are widely used in the fields of 3C electronics and general machinery; The horizontal machining center reduces the number of clamping times through multi-station processing, especially suitable for box parts, and an auto parts factory has increased the processing efficiency after use by 40%.

The gantry machining center is known for its large stroke and high rigidity, and the 25-meter ultra-heavy gantry machining center of Qizhong CNC has set an extreme manufacturing record, which can process large parts of 600 tons. With the advantage of multi-axis linkage, the five-axis machining center solves the problem of complex surface machining of aerospace titanium alloys, and the machining accuracy can reach ±0.005mm. The turning-milling composite machining center integrates multiple processes such as turning and milling, such as the vertical turning-milling and grinding composite equipment of full-weight CNC, which realizes the whole process of processing the workpiece at one time, and the efficiency is increased by 6 times.

From the perspective of design concept, the modular design allows the equipment to combine functions on demand, while the high-precision full closed-loop technology ecological chain provides guarantee for high-end processing through multi-link precision control.

2. Machining center core technologies: what are the keys to improving performance?

Core technology is the core of the competitiveness of the machining center. As the "brain" of the CNC system, Siemens Sinumerik ONE can achieve multi-channel collaborative control and increase response speed by 30%; The direct drive technology eliminates the traditional gear transmission, and the direct drive table design of the full-weight CNC eliminates the cumulative error and makes the positioning accuracy reach the micron level.

The combined application of electric spindle and linear motor improves the machining speed and accuracy simultaneously, and the micromachining efficiency is increased by 50% after use in a 3C electronic processing plant. Triple Folding Temperature Control Technology Dynamically adjusted by 200+ temperature sensors, this technology from Okuma Machine Tools extends the life of the guide rail by 2 times. Active vibration damping technology and hydrostatic bearings solve the vibration problem in high-speed machining, and the hydrostatic guide technology of the full-weight CNC allows the 5-ton tool holder to be pushed by fingers, and the friction coefficient is close to zero. Together, these technologies support micron/sub-micron machining accuracy to meet high-end manufacturing needs.

3. Intelligent technology of machining center: how to achieve "thinking" production?

Intelligent technology is reshaping the production logic of machining centers. Digital twin technology links virtual production lines with physical equipment, and Shenyang Machine Tool's iSESOL platform shortens order delivery cycles by 35% through this technology; Edge computing localizes data processing, reduces cloud dependence, and improves the real-time scheduling response speed of an unmanned chemical plant to milliseconds.

Augmented reality (AR) technology has changed the operation mode, and Huazhong CNC's iHP terminal displays the machining path through AR, reducing the tool setting time for novices from 15 minutes to 2 minutes; The multi-screen collaboration of human-machine interface (HMI) realizes the integration of operation, monitoring, and programming, improving the convenience of operation. The combination of AI algorithms to optimize production scheduling and real-time monitoring systems resulted in a 90% reduction in unplanned downtime and a 75% reduction in maintenance costs at an automotive gear plant. The implementation of these technologies has made real-time scheduling of unmanned chemical plants a reality, and a new energy vehicle "black light factory" has achieved 24-hour continuous production, with a yield rate of 99.2%.

4. Machining center precision control technology: how to keep the "micron-level" bottom line?

Precision control is the core demand of machining centers. Positioning accuracy and repeatable positioning accuracy are key indicators, and high-end equipment can reach ±0.003mm and ±0.001mm respectively; The circle interpolation deviation directly affects the surface processing quality, which can be controlled within 0.002mm through algorithm optimization.

Thermal deformation suppression technology solves the problem of thermal drift in processing through symmetrical structure design and temperature control system. Full closed-loop control combined with nanoscale grating scale realizes real-time error compensation, and the ultra-precision machining accuracy is improved to the nanometer level after use in an optical component processing plant. The high rigidity design of the roller guide ensures the stability of movement, and with the accuracy stability control system, the long-term operation accuracy attenuation rate of the equipment is less than 0.5%. The following table shows the application scenarios of different accuracy levels:

| Accuracy level | Positioning accuracy | Typical applications: |

| Normal level | ±0.01mm | General Machining |

| Precision grade | ±0.005mm | Auto parts processing |

| Ultra-precision grade | ±0.001mm | Medical devices, optical parts |

5. Machining center automation and flexible manufacturing: how to adapt to multi-variety production?

Automation and flexible manufacturing are key to market changes. The Automatic Tool Changer (ATC) reduces tool change time to less than 1 second, greatly improving machining continuity. The pallet changer (APC) enables parallel workpiece clamping and processing, reducing the work-in-progress backlog by 60% after use in a valve factory.

Industrial robot integration automates loading and unloading, and Genesis Group's truss robot solution shortens the processing cycle time of new energy vehicle motor housings by 30%; Flexible automation supports multi-mix line production, and a 3C factory uses this technology to quickly switch between 50 products. Multi-axis linkage and compound machining capabilities reduce complex parts machining by 50%, and Genesis' five-axis machine machines machine machines machine shock towers in just 480 seconds. Together, these technologies support unattended production, reducing the number of people in a single shift from 8 to 1 in a semiconductor device processing plant.

6. Customized solutions for the machining center industry: how to adapt to different industries?

The processing needs of different industries vary significantly. In the field of integrated die-casting parts processing for new energy vehicles, Genesis Group provides special machine tools and automation solutions for motor housings, battery trays and other components, and it only takes 30 minutes to process motor housings in three sequences. Aerospace titanium alloy machining has extremely high requirements for equipment rigidity and precision, and the five-axis machining center is cooperated with a special process package to achieve efficient processing of complex structural parts.

3C electronic micromachining requires high precision and high speed, and the vertical machining center is equipped with a micron-level grating ruler to meet the processing needs of small parts; Medical device precision machining requires strict surface quality, and ultra-precision machining centers can achieve surface roughness of Raμm. Ultra-precision machining of optical components and semiconductor device processing rely on nanoscale precision control, and a dedicated intelligent process package ensures processing consistency. The core of customized solutions is "on-demand matching", and Genesis' turnkey services cover the whole process from scheme design to production training, which has been implemented in many key enterprises.

7. Core functional components of machining centers: which components determine equipment performance?

The core functional components are the "key skeleton" of the machining center. The dual direct drive torque motor cradle table provides high rigidity and high-precision rotational motion, suitable for five-axis parallel machining; the combination of ceramic bearings and hydrostatic guide rails enables the electric spindle speed to exceed 20000rpm and extend the service life by 3 times.

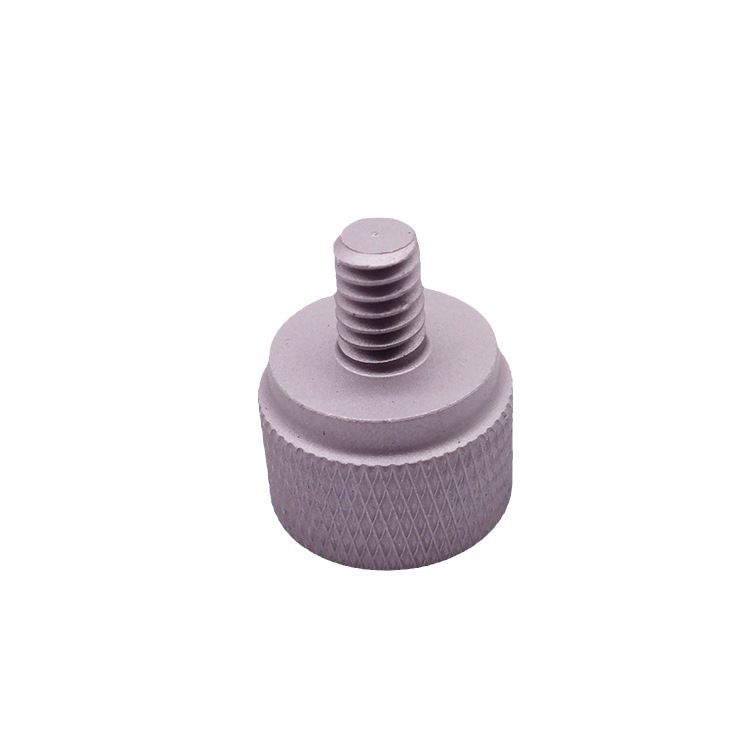

The mineral resin bed and natural granite base have excellent vibration resistance and thermal stability, reducing the impact of environmental factors on machining accuracy. The ball screw is the transmission core, and the accuracy level can reach C1, and the positioning error is less than 0.002mm/m. The capacity of the tool magazine system and the tool change speed directly affect the machining efficiency, and the chain tool magazine can accommodate 60+ tools, and the tool change time is as low as 0.8 seconds; the precise design of the fixture and chuck ensures the workpiece clamping accuracy, and the repeated positioning accuracy of the hydraulic chuck can reach ±0.002mm.

8. Yigu Technology's view

The development of machining centers has entered a new stage of "high precision, intelligence, and customization". From the perspective of technology trends, the deep integration of core technologies such as direct drive technology, intelligent temperature control, and digital twins is promoting the leap in machining accuracy from micron to nanometer. In terms of industry applications, the customization needs of new energy vehicles, aerospace and other fields have prompted equipment manufacturers to transform from "selling products" to "providing overall solutions". For enterprises, choosing a machining center needs to take into account their own industry characteristics, processing accuracy requirements, and intelligent upgrade needs, and give priority to suppliers with independent research and development capabilities of core technologies and perfect service systems. In the future, machining centers will further develop in the direction of "human-machine collaboration, green efficiency, and extreme manufacturing" and become the core support of intelligent manufacturing.

9. FAQ FAQ

- How to choose between vertical and horizontal machining centers?

Answer: vertical machining centers are suitable for small and medium-sized parts, single process processing, and lower cost; horizontal machining centers are suitable for large box parts, multi-process continuous processing, higher efficiency, and can be selected according to the size and process complexity of the processed parts.

- What are the core advantages of 5-axis machining centers?

Answer: The five-axis machining center can realize multi-directional linkage machining, without multiple clamping, which can effectively reduce clamping errors, especially suitable for the processing of complex curved surfaces and special-shaped structural parts, and the machining efficiency and accuracy are better than traditional three-axis equipment.

- What are the practical benefits of intelligent technology in machining centers?

A: Intelligent technology can reduce human intervention, increase production efficiency by 30%-60%, improve processing accuracy by 2-3 times, reduce unplanned downtime by more than 80%, and reduce maintenance costs and energy consumption, making it suitable for mass production and unmanned workshop construction.

- What are the core services of customized machining solutions?

Answer: The core includes special machine tool selection, process scheme design, fixture tool matching, automation system integration, debugging training and after-sales support, which can provide full-process services from scheme design to production and operation according to industry characteristics and parts processing needs.

- How to ensure the long-term accuracy and stability of the machining center?

Answer: It is necessary to select equipment with high rigidity bed and precision transmission components, regularly carry out precision calibration and maintenance, optimize the environmental temperature of the workshop (controlled at 20±2°C), and use technologies such as full closed-loop control and thermal deformation suppression to reduce the influence of external factors.