In the field of modern special machining, spark erosion machining has become the core technology for processing difficult-to-machine materials such as cemented carbide and titanium alloy with the unique advantages of non-contact machining. Whether it's mold manufacturing or aerospace component machining, this technology plays an indispensable role. This article will comprehensively dismantle the core points of EDM from principles to applications, from equipment to parameters, and help you thoroughly understand the key technology of this industrial manufacturing.

1. The core concept and working principle of EDM

To master EDM, you must first clarify its definition and the physical logic behind it. In simple terms, EDM, also known as electrical discharge machining or electro-etching, is a special processing technology that uses the high temperature generated by pulsed spark discharge between the electrode and the workpiece to erode conductive materials. Its core advantage lies in non-contact machining, which eliminates the need for direct tool contact with the workpiece, so it does not generate cutting forces, making it particularly suitable for machining complex cavities and precise tiny parts.

At the heart of its working mechanism is the principle of electrocorrosion, and the specific process can be divided into three key steps:

- Dielectric breakdown: The electrode and the workpiece are filled with insulating working fluid (such as kerosene, deionized water), and a high-voltage electric field is generated between the two poles under the action of pulsed power supply. When the electric field strength exceeds the insulation strength of the working fluid, it will break through the medium to form a discharge channel.

- Thermal erosion: The discharge channel instantly generates extremely high temperatures (up to 10,000°C or more), causing the metal material on the surface of the workpiece to melt or even vaporize quickly. At the same time, the high temperature will cause the surrounding working fluid to expand sharply, and the resulting shock wave will wash away the molten metal chips.

- Clearance Maintenance: The servo control system adjusts the distance between the electrode and the workpiece in real time to maintain a stable discharge gap (usually from a few microns to tens of microns) to ensure that the discharge process is continuous and stable.

Practical case: When processing carbide stamping model cavities, a mold factory uses CNC EDM technology to successfully process complex curved cavities through the pulse discharge of copper electrodes, with dimensional accuracy controlled within ±0.005mm, solving the problem of traditional cutting processing that is difficult to handle cemented carbide materials.

2. The main process types and application fields of EDM machining

According to different processing methods and application scenarios, EDM is mainly divided into two core processes, deriving a variety of subdivision types, covering multiple high-end manufacturing fields.

(1) Comparison of core process types

| Process type: | Subdivision of categories | Technical characteristics: | Applicable scenarios |

|---|---|---|---|

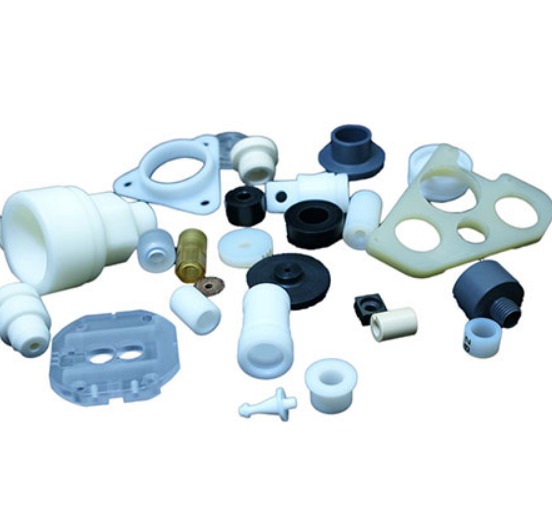

| EDM machining | Precision micro EDM, small hole processing | Molding electrodes are used to achieve complex cavities through profiling processing; Microscopic EDM can process micron-sized holes and narrow slits | injection molding, die-casting model cavity processing; Precision nozzle and medical device microporous processing |

| EDM wire EDM | Fast silk, middle silk, slow silk | The continuously moving wire electrode is used as the tool electrode to cut the workpiece into shape; The slow filament has the highest accuracy and the cost of fast filament is the lowest | Stamping dies, convex and concave dies, aerospace complex contour parts, precision tool processing |

Among them, the slow wire uses brass wire or galvanized wire as the wire electrode, and the electrode wire can be used for one time, with a processing accuracy of up to ±0.001mm and a surface roughness Ra as low as 0.1μm. Fast walking wire is recycled with molybdenum wire, which has a lower cost but relatively poor accuracy and surface quality, making it suitable for batch processing that does not require high precision.

(2) Typical application fields

- Mold manufacturing: This is the most important application area of EDM, whether it is stamping molds, injection molds or die-casting molds, complex cavities and cores are inseparable from EDM machining. For example, the cavity of the automobile bumper injection mold can only be completed by EDM due to its complex shape and high material hardness.

- Aerospace parts: Titanium alloy blades and engine combustion chamber parts in the aerospace field have high material strength and good heat resistance, which is difficult to traditional cutting and processing, and EDM can achieve high-precision and deformation-free processing.

- Medical Device Processing: The complex textures of stainless steel microporous catheters and orthopedic implants in medical devices require precise and micro-EDM processing to meet the stringent requirements of biocompatibility and dimensional accuracy.

- Difficult-to-machine material processing: For difficult-to-cut materials such as cemented carbide and ceramics, EDM is one of the most effective machining methods. For example, the edge strengthening of carbide tools can significantly improve the service life of the tool through EDM treatment.

3. Key equipment, systems and core components of EDM machining

A complete EDM system consists of the main body of the machine tool, pulse power supply, servo control system, electrode and working fluid system, and each component directly affects the machining accuracy and efficiency.

- EDM machine tool: The machine tool structure includes the bed, worktable, spindle head and other parts, the worktable is responsible for clamping the workpiece, and the spindle head controls the precise movement of the electrode. The high-end CNC EDM machine tool adopts a granite bed, which has excellent rigidity and vibration resistance, which can effectively ensure the stability of processing.

- Pulse Power Cabinet: This is the "energy core" of EDM and is responsible for providing controlled pulse currents and voltages. The amount of discharge energy can be controlled by adjusting the pulse width (pulse duration) and pulse interval (pulse interval time) – the larger the pulse width, the higher the discharge energy, the faster the processing speed, but the surface quality will decrease.

- Servo control system: The core function is to maintain a stable discharge gap, when the electrode is too close to the workpiece, the system will drive the electrode backward; If the distance is too far, the electrode will be driven forward. High-precision servo systems are the key to ensuring dimensional accuracy.

- Electrodes vs. Wire Electrodes:

- Commonly used copper electrodes and graphite electrodes in forming processing: copper electrodes have good conductivity and low loss, suitable for high-precision processing; Graphite electrodes are low-cost, lightweight, and suitable for large-scale cavity processing.

- Brass wire and galvanized wire are commonly used in wire EDM processing: brass wire is highly versatile, and galvanized wire has lower electrode loss and higher processing accuracy due to the "discharge protection effect" of the zinc layer on the surface.

- Working fluid system: Contains working fluid (kerosene, deionized water) and filtration device. The role of working fluid is insulation, cooling, and chip evacuation; The filtration device is responsible for removing metal debris from the working fluid to prevent debris from affecting the discharge process. For example, slow filament processing often uses deionized water as the working fluid, allowing for higher machining accuracy.

4. Process parameters, accuracy and surface quality control of EDM machining

To achieve high-quality EDM, it is necessary to accurately control the process parameters and balance the relationship between processing speed, electrode loss and surface quality.

(1) Core process parameters and their impacts

| Process parameters | definition | Impact on processing |

|---|---|---|

| Pulse wide | The duration of a single pulse | The increase of pulse width→ the increase of discharge energy→ the acceleration of processing speed→ the increase of surface roughness→ increase of electrode loss |

| Between veins | The time between the two pulses | The increase of pulse interval → decrease of discharge frequency→ slow down the processing speed→ decrease electrode loss→ improve processing stability |

| Peak current | The maximum value of the pulse current | The increase of current→ the increase of discharge energy→ the acceleration of processing speed→ decrease of surface quality |

Practical skills: When rough machining, you can choose large pulse width, large current, and small pulse interval to ensure processing efficiency first; When finishing, choose small pulse width, small current, and large pulse interval to ensure surface quality and accuracy.

(2) Machining accuracy and surface quality indicators

- Accuracy metrics: including dimensional accuracy, contour accuracy, and angular retention. For example, when processing the parting surface of an injection mold, the contour accuracy is required to reach ±0.002mm, and the edge and corner retention directly affects the mold's clamping accuracy and product quality.

- Surface quality index: The core is surface roughness (Ra), and it is necessary to pay attention to the surface metamorphic layer and recasting layer. EDM will form a metamorphic layer about a few microns thick on the surface of the workpiece, if the metamorphic layer is too thick, it will affect the wear resistance and corrosion resistance of the part. By repeatedly finishing (polishing), the thickness of the metamorphic layer can be effectively reduced and the Ra value can be controlled below 0.2μm.

Case data: A precision parts processing plant adopts the three-stage EDM process of "roughing + semi-finishing + finishing", with a rough Ra value of 6.3μm, which drops to 1.6μm after semi-finishing and reaches 0.4μm after finishing, which fully meets the requirements of high-precision parts.

Yigu Technology Professional Perspective

As a procurement and technical service team deeply involved in the field of industrial manufacturing, Yigu Technology believes that the core competitiveness of EDM lies in its adaptability to difficult-to-machine materials and complex structures. In cross-border B2B procurement scenarios, when choosing EDM equipment or outsourcing services, enterprises need to focus on the servo control accuracy of the equipment, the adaptability of electrode materials, and the supplier's process parameter debugging capabilities. At the same time, with the development of intelligent manufacturing, high-end EDM systems with digital simulation and online monitoring functions will become the mainstream choice of the future manufacturing industry. Enterprises should combine the precision requirements and cost budgets of their own products to choose the most cost-effective processing scheme to avoid the waste of resources caused by the blind pursuit of high-end equipment.

FAQ

- Can EDM process non-metallic materials? No. The premise of EDM is that the workpiece must be a conductive material, and non-metallic materials cannot be processed using this technology because they cannot form a discharge channel.

- Is there a limit to the thickness of the workpiece for EDM machining? Yes. The thickness of the workpiece will affect the stability of the discharge gap and the chip evacuation effect, generally the thickness of fast wire can be processed within 500mm, and the thickness of slow wire processing is usually not more than 300mm, depending on the machine tool model and electrode wire tension.

- How to reduce electrode loss in EDM machining? There are three ways to choose an electrode material with low loss (such as copper electrode); Optimize process parameters to reduce pulse width and peak current; Negative polarity processing is used (workpiece is connected to negative electrode, electrode is connected to positive electrode) to reduce the amount of thermal erosion removal of electrodes.

- Does the surface metamorphic layer of EDM affect part performance? Yes. For parts with high load and high wear resistance, too thick metamorphic layer will reduce the service life of the part. The metamorphic layer can be removed through subsequent grinding, polishing and other processes, or multiple finishing can be used during processing to reduce the thickness of the metamorphic layer.