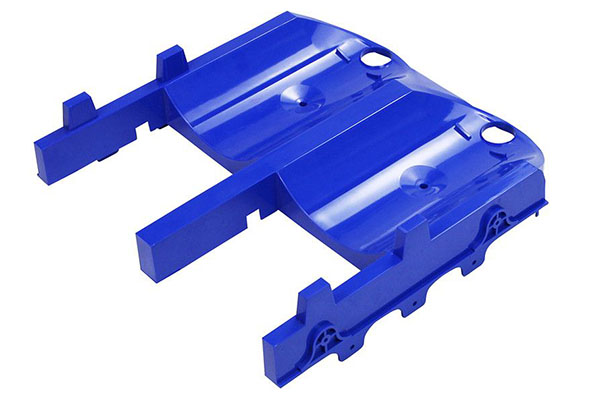

Navigating the world of Medical Plastic Mold China? This definitive guide covers quality, cost, customization, and key insights for sourcing reliable, high-performance medical-grade injection molds.

Introduction

When sourcing critical components for the medical device industry, the phrase "Made in China" often surfaces with a mix of high interest and cautious inquiry. Specifically, for medical plastic injection molds, the global market increasingly looks to China as a powerhouse. But beyond the well-known cost advantages lies a more complex landscape of quality, technology, and capability. This comprehensive guide cuts through the noise, providing engineers, product developers, and procurement specialists with a clear, authoritative look at what it truly means to source a Medical Plastic Mold in China. We'll explore the rigorous quality assurance frameworks, analyze the undeniable cost-effectiveness, and delve into the sophisticated customization capabilities that define today's top-tier Chinese mold manufacturers.

Is the Quality of Medical Plastic Molds from China Reliable?

The short answer is yes, but with a critical caveat: reliability is directly tied to partnering with the right manufacturer. Leading Chinese mold makers serving the global medical market operate on a paradigm that rivals and often surpasses international standards. Their commitment to quality is not an afterthought; it's engineered into every step of the process, built upon three fundamental pillars.

Stringent Material Selection for Biocompatibility and Durability

The journey to a reliable mold begins with the raw materials. Medical-grade molds demand steels that offer far more than just hardness. Top manufacturers exclusively use premium grades like Stavax ESR (AISI 420 modified), German 1.2316, or Japanese S136H stainless steel. The choice is driven by specific requirements:

- Corrosion Resistance: Medical plastics are often sterilized using autoclaves (high-pressure steam), ethylene oxide (EtO), or chemical baths. Standard tool steels would corrode, causing part defects and contamination. Premium corrosion-resistant steels ensure mold longevity and prevent particulate generation.

- Excellent Polishability: Medical device surfaces frequently require optical clarity or ultra-smooth finishes to prevent bacterial adhesion. The selected steel must be capable of achieving a mirror polish (e.g., SPI A1 / #1 finish) consistently across the cavity.

- Uniform Hardness & Machinability: Consistency is key for high-volume production. These steels provide uniform hardness (typically HRC 48-52) after heat treatment, minimizing wear and ensuring dimensional stability over millions of cycles.

Case in Point: A manufacturer producing microfluidic chips for diagnostic testing needed a mold that could produce parts with sub-micron channel accuracy and a flawless optical surface. By utilizing German 1.2316 steel and applying a specialized sequential polishing technique, the Chinese mold maker achieved a defect-free SPI A1 finish, enabling the client to meet stringent FDA scrutiny on part clarity and functionality.

Advanced Manufacturing Technologies: Precision as Standard

Gone are the days of manual craftsmanship alone. The precision required for modern medical device molds—think meso-fluidic channels, living hinges, or micro-needle arrays—is achieved through a suite of advanced technologies:

| Technology | Application in Medical Mold Making | Key Benefit |

|---|---|---|

| 5-Axis CNC Machining | Complex, free-form surfaces; undercuts; conformal cooling channels. | Creates geometries impossible with 3-axis machines, improving accuracy and reducing need for multi-piece assemblies. |

| High-Speed Machining (HSM) | Fine detailing on mold cores and cavities; reduced electrode use for EDM. | Delivers superior surface finish directly from the machine, minimizing manual polishing and potential errors. |

| Wire & Sinker EDM | Creating sharp internal corners; texturing; machining hardened steels. | Essential for achieving the precise, burr-free edges required for mold components like ejector pins and core pins. |

| Laser Welding & Cladding | Repairing damaged cavities; applying wear-resistant coatings to specific areas. | Extends mold life dramatically and allows for design modifications without scrapping the entire mold block. |

The integration of these technologies into a Digital Thread—from CAD design to CAM programming to CMM inspection—ensures that the final mold is a perfect digital-physical match.

A Rigorous Quality Control System: From CAD to First Article

Quality isn't just inspected; it's verified at every milestone. Reputable manufacturers implement a stage-gate quality control process:

- Design for Manufacturability (DFM) Review: Before metal is cut, engineers analyze the part design for potential molding issues (sink marks, warpage, stress concentrations) and propose modifications.

- In-Process Verification: Critical dimensions are checked after rough machining, heat treatment, and finish machining using CMM (Coordinate Measuring Machines) and high-precision gauges.

- Final Mold Qualification: The complete mold is measured against the original 3D CAD model. A T1 sample run is conducted, and the resulting plastic parts undergo a First Article Inspection (FAI). This often includes:

- Dimensional Report: Full CMM check of critical part features.

- Material Certification: Traceability for the plastic resin used (e.g., USP Class VI, ISO 10993 compliant).

- Functional Testing: If applicable, testing the part in its intended assembly or environment.

This闭环 (closed-loop) system provides documented evidence of compliance, which is invaluable for your own regulatory submissions to bodies like the FDA or EMA.

How Cost-Effective Are Chinese Medical Plastic Molds?

The economic advantage is a primary driver, but it's essential to understand why and how much. The savings are structural and significant, often ranging from 30% to 50% compared to molds from North America or Western Europe, without sacrificing quality when partnering with a top-tier supplier.

A Streamlined, Cost-Saving Production Ecosystem

The cost-effectiveness stems from a deeply integrated supply chain and operational efficiency:

- Localized Supply Chain: Access to raw mold steel, standard components (like DME or HASCO mold bases), and precision machining services is localized, reducing material cost and lead time for procurement.

- Technical Labor Efficiency: A large pool of skilled CNC programmers, mold polishers, and technicians, while commanding competitive wages, offers a favorable labor cost structure. This allows for more hands-on, detailed work without exorbitant cost inflation.

- High-Density Expertise: Many factories are vertically integrated, housing design, machining, EDM, polishing, and try-out under one roof. This reduces logistics, communication overhead, and project management friction.

Objective Comparison with International Counterparts

A fair comparison must look beyond the initial quote.

| Factor | Top-Tier Chinese Mold Maker | Typical Western Mold Maker |

|---|---|---|

| Initial Mold Cost | Significantly Lower (30-50% savings) | Higher |

| Lead Time | Competitive to Faster (due to 24/7 shop operations) | Often longer |

| Technical Capability | Equal for most applications (5-axis, HSM, etc.) | Equal |

| Material Quality | Equal (using same int'l steel grades) | Equal |

| Communication & IP Protection | Can be a concern; mitigated by clear contracts and NDAs with reputable firms. | Perceived as lower risk. |

| Total Cost of Ownership (TCO) | Often Lower, when factoring in cost per part over mold life. | Higher initial investment. |

The key is that for medically compliant molds, the cost savings are no longer derived from cutting corners, but from systemic efficiencies. This allows medical device startups to lower their capital expenditure (CapEx) and established companies to stretch their development budgets further.

Can Chinese Mold Makers Handle Complex Customization?

Absolutely. In fact, the ability to handle highly customized, low-to-medium volume medical molds is a defining strength of the agile Chinese manufacturing sector. This is crucial for the medtech industry, which thrives on innovation and patient-specific solutions.

Meeting Diverse and Evolving Design Requirements

Whether you're developing a surgical instrument handle with an ergonomic overmold, a complex IV connector, or a single-use biopsy device, the design flexibility is extensive. Experienced engineers are adept at working with:

- Multi-Material & Overmolding: Creating soft-touch grips or seals within a hard plastic frame.

- Micro-Molding: For tiny components like catheter tips or hearing aid parts, requiring extreme precision.

- Cleanroom Molding: Designing molds and processes for parts that are molded and assembled in a ISO Class 7 or 9 cleanroom environment to prevent contamination.

Quick Turnaround for Custom Orders and Prototypes

The integrated production model enables remarkable speed for custom medical molds. A common workflow:

- Rapid DFM Feedback: Within 48 hours of receiving a 3D file.

- Concurrent Engineering: Mold design and material ordering happen in parallel.

- Accelerated Sampling: The focus on getting to T1 samples quickly allows for rapid design iteration. It's not uncommon for a prototype mold (aluminum or softer steel) to be delivered in 4-6 weeks for design validation, followed by the production-grade mold.

- Design Change Responsiveness: The in-house capabilities make implementing engineering change orders (ECOs) faster and more cost-effective than in a fragmented supply chain.

This agility reduces time-to-market significantly, a critical factor in the competitive medical device field.

FAQ: Medical Plastic Mold China

What certifications should I look for in a Chinese medical mold maker?

Prioritize manufacturers with ISO 13485:2016 certification (Quality Management for Medical Devices). This is non-negotiable. Additionally, familiarity with FDA 21 CFR Part 820 and the ability to provide a full Device History Record (DHR) for the mold itself are strong indicators of a quality-focused partner.

How is intellectual property (IP) protected when manufacturing in China?

Protection starts with a legally binding Non-Disclosure Agreement (NDA) and a clear Intellectual Property clause in the manufacturing contract. Reputable companies value their long-term business relationships over short-term gains and have robust internal IP protection protocols. Conducting an audit or visiting the facility can also build trust.

What is the typical lead time for a production-grade medical mold from China?

Lead times vary by complexity. For a standard, single-cavity medical plastic injection mold in hardened stainless steel, expect 10-14 weeks for design, manufacturing, sampling, and approval. Prototype or aluminum molds can be delivered in 4-8 weeks. Always factor in time for comprehensive sample testing and approval.

Can I get a complete turnkey solution, from mold to finished plastic parts?

Yes, most leading manufacturers offer end-to-end services. They can handle the mold design and manufacturing, source USP Class VI compliant resins, perform cleanroom injection molding, and conduct secondary operations (ultrasonic welding, RF sealing, assembly, packaging). This simplifies your supply chain and ensures accountability.

What are the payment terms typically like?

Standard terms involve a 30-50% deposit to commence work, with the balance paid before shipment of the completed mold. For established relationships, other terms can be negotiated. Never pay 100% upfront.

Contact YIGU Technology for Your Custom Medical Mold Manufacturing

Navigating the landscape of Medical Plastic Mold manufacturing in China requires a partner that embodies the principles of Quality, Precision, and Integrity. If you are developing a Class I, II, or III medical device and require a mold that meets the highest standards of biocompatibility, durability, and precision, a specialized conversation is the next step.

YIGU Technology specializes in the design and manufacture of high-performance, medical-grade injection molds. With a foundation in ISO 13485:2016 certified processes, a commitment to advanced manufacturing technologies, and a proven track record in serving global medtech companies, we transform complex medical device designs into reliable, production-ready reality.

Ready to discuss your project?

- Visit our website to explore our capabilities and case studies.

- Submit your 3D part files for a confidential Design for Manufacturability (DFM) review and detailed quotation.

- Connect with our engineering team to discuss your material, regulatory, and volume requirements.

Let's build the tool that brings your life-saving innovation to market.