Introduction

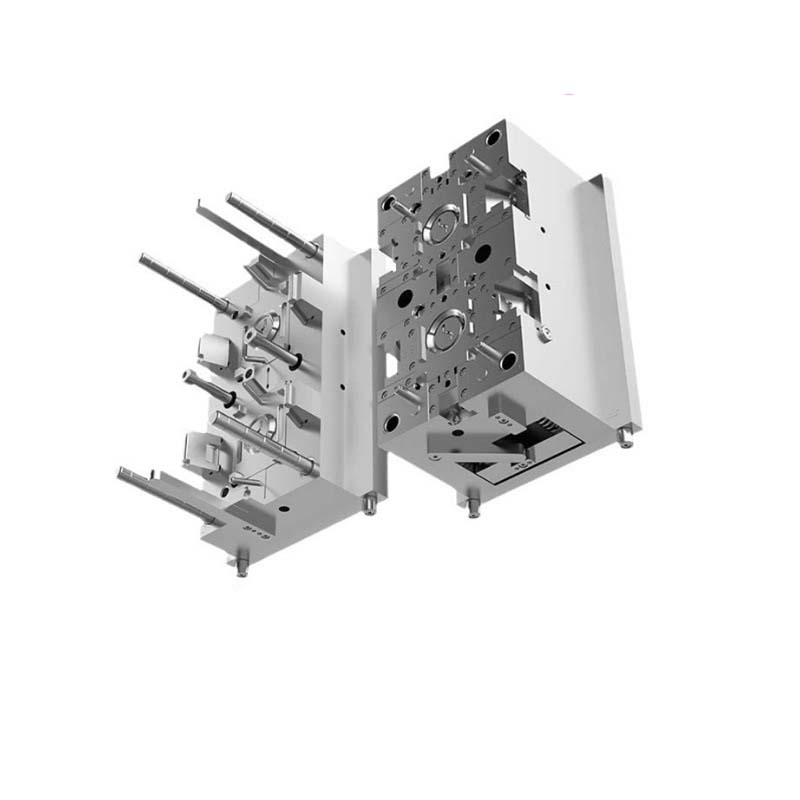

In the world of manufacturing, injection molds play a pivotal role. They are the key tools that enable the mass - production of high - quality plastic products with precision and efficiency. From the tiniest components in electronic devices to large - scale automotive parts, injection molds are involved in the creation of a vast array of items that we use in our daily lives.

The injection molding process is highly efficient, capable of producing complex - shaped parts in large quantities. It allows for tight tolerances, ensuring that each product meets the required specifications. Moreover, it can work with a wide variety of materials, from common plastics like polyethylene and polypropylene to high - performance engineering plastics.

When it comes to sourcing injection molds, an increasing number of businesses are turning their attention to China. China has emerged as a global powerhouse in the injection mold industry, offering a combination of cost - effectiveness, high - quality production, and a vast pool of technical expertise. In the following sections, we will explore in detail the numerous benefits of choosing Injection Mold China for your manufacturing needs, and why it could be the smartest decision for your business.

Cost - effectiveness: A Major Draw

Lower Production Costs

One of the most compelling reasons to choose Injection Mold China is the cost - effectiveness it offers. China has a well - developed industrial supply chain, which means that manufacturers can source high - quality raw materials at competitive prices. For example, in the global market, the price of steel, a common material for injection molds, can vary significantly. In China, due to its large - scale steel production and a vast number of steel suppliers, the cost of purchasing steel for mold manufacturing can be up to 20 - 30% lower compared to some Western countries.

Labor costs also play a crucial role in cost - effectiveness. The labor force in the injection mold industry in China is both skilled and relatively inexpensive. According to industry reports, the average labor cost for mold manufacturing in China is approximately one - third to one - fifth of that in developed countries like the United States or Germany. This significant difference in labor cost directly translates into lower production costs for injection molds. For a medium - sized injection mold project, the labor cost savings can amount to tens of thousands of dollars, making a substantial impact on the overall budget.

Economies of Scale

China's position as a global manufacturing hub allows injection mold manufacturers to benefit from economies of scale. With a high demand for injection molds both domestically and internationally, Chinese manufacturers can produce large quantities of molds. For instance, in the automotive industry, a Chinese injection mold manufacturer might receive an order for thousands of molds for producing car interior components. By producing such a large volume, the fixed costs, such as the cost of equipment, factory rent, and management expenses, can be spread out over a greater number of units. As a result, the unit cost of each injection mold can be reduced by 15 - 25%.

A case in point is a major electronics company that switched its injection mold sourcing to a Chinese manufacturer. Before, they were producing 500,000 plastic casings for their devices annually using molds from a European supplier. After moving to a Chinese injection mold supplier, the production volume increased to 1 million units per year. Due to the economies of scale achieved by the Chinese manufacturer, the electronics company not only saw a 20% reduction in the cost per mold but also a significant improvement in the production efficiency, as the Chinese supplier was able to invest in more advanced equipment with the increased order volume. This example clearly demonstrates how choosing Injection Mold China can lead to substantial cost savings through economies of scale.

High - Quality Manufacturing

Advanced Technology and Equipment

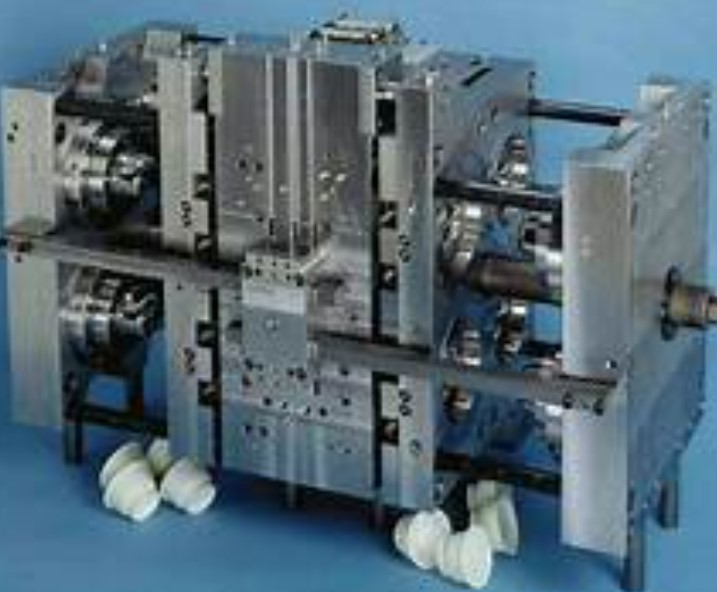

Chinese injection mold manufacturers are equipped with state - of - the - art technology and equipment, which are crucial for producing high - quality molds. High - precision machining centers are widely used. For example, many factories have five - axis high - speed machining centers. These centers can achieve extremely high - speed rotation of the spindle, reaching up to 40,000 rpm in some advanced models. With a high - speed spindle, they can use small - diameter milling cutters for processing. This allows for the production of molds with complex three - dimensional surfaces, such as those required for intricate automotive interior parts or high - end consumer electronics housings. The machining accuracy of these high - precision machining centers can be as high as ±0.001mm, ensuring that the molds produced meet the most stringent dimensional requirements.

EDM (Electrical Discharge Machining) is another important technology. EDM is especially useful for creating molds with complex shapes, such as those with deep grooves, narrow slots, and fine - detailed features. It can accurately process high - hardness materials like hardened steel and carbide, which are often used in injection molds that require high wear resistance. For instance, in the production of molds for precision medical device components, EDM can create the precise internal structures and fine surface finishes that are necessary for the proper functioning of the medical devices. Some advanced EDM machines can achieve a surface roughness of Ra ≤ 0.1μm, which is essential for producing molds that can create smooth - surfaced plastic products.

Stringent Quality Control

Quality control is a top priority for Chinese injection mold manufacturers. Many of them adhere to international quality control standards, such as ISO 9001. This standard ensures that the entire production process, from raw material procurement to the final product delivery, is strictly monitored.

Before production, raw materials are carefully inspected. For example, the steel used for mold manufacturing must meet specific chemical composition and physical property requirements. Once the production begins, in - process inspections are carried out at multiple stages. Operators use advanced measuring tools, such as coordinate measuring machines (CMMs), to check the dimensions of the mold components during machining. These CMMs can measure with an accuracy of up to ±0.0001mm, ensuring that each part of the mold is within the specified tolerance range.

After the molds are completed, final inspections are conducted. A comprehensive quality assessment includes checking the mold's dimensional accuracy, surface finish, and functionality. According to industry statistics, the qualified rate of injection molds produced by Chinese manufacturers that follow strict quality control procedures can reach over 98%. This high - quality output means that customers can have confidence in the performance and longevity of the molds they purchase from China, leading to fewer production issues and lower costs associated with mold replacements and repairs in the long run.

Rich Industry Experience and Skilled Workforce

Long - standing Industry Presence

China's injection mold industry has a long and rich development history. It can be traced back to several decades ago when the country began to focus on the manufacturing sector. In the early days, the industry mainly focused on basic mold production to meet the domestic demand for simple plastic products. However, with the continuous development of the economy and the increasing demand from various industries, especially the rapid growth of the electronics, automotive, and consumer goods industries, the injection mold industry in China has experienced significant growth and transformation.

Over the past few decades, Chinese injection mold manufacturers have accumulated a wealth of experience in handling different types of projects. They have successfully completed projects for a wide range of products, from small - scale components for daily - use products to large - scale, high - precision molds for automotive and aerospace industries. For example, in the automotive industry, Chinese manufacturers have been involved in producing injection molds for car bumpers, interior panels, and various engine components. Through continuous innovation and improvement in these projects, they have mastered the complex processes and techniques required for automotive injection mold production, such as the design and manufacturing of molds with complex curved surfaces and high - strength material requirements. This long - standing industry presence and the wealth of project experience have made Chinese injection mold manufacturers highly capable of handling even the most challenging manufacturing needs.

Skilled and Trained Workers

The injection mold industry in China benefits from a large number of skilled and trained workers. These workers undergo comprehensive training programs that cover various aspects of injection mold manufacturing. Technical schools and vocational training centers across the country offer specialized courses in mold design, manufacturing, and maintenance. In these courses, students learn theoretical knowledge, such as mold design principles, material properties, and manufacturing processes, as well as practical skills through hands - on training in well - equipped workshops.

For instance, in a typical training program, students will learn how to use CAD/CAM software for mold design. They will practice creating 3D models of injection molds, simulating the injection molding process, and generating tool paths for machining. In the workshop, they will operate various types of equipment, including CNC machining centers, EDM machines, and milling machines, to fabricate mold components. After completing the training, these workers enter the industry and bring their skills and knowledge to the manufacturing floor.

When faced with complex mold problems, these skilled workers have the ability to find effective solutions. Take a case where a mold for producing high - precision medical device components developed a problem during the production process. The mold's internal channels, which were crucial for the proper functioning of the medical device, had some irregularities that affected the quality of the plastic parts. A team of skilled workers in the Chinese factory quickly analyzed the problem. They used their knowledge of mold materials and manufacturing processes to determine that the issue was caused by the wear of a specific cutting tool during the mold machining process. They then adjusted the machining parameters and replaced the worn - out tool. After making these adjustments, they carefully inspected the mold using advanced measuring equipment to ensure that the internal channels met the required precision. Thanks to their skills and experience, they were able to solve the problem promptly, minimizing production downtime and ensuring the quality of the final products. This example clearly demonstrates the high - level skills and problem - solving abilities of the skilled workforce in the Injection Mold China industry.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology firmly believes in the advantages of choosing Injection Mold China. With over 30 years of experience in the field, we have witnessed the remarkable growth and development of the injection mold industry in China.

Our long - standing presence has allowed us to serve a diverse range of industries, including automotive and medical. In the automotive industry, we've provided high - quality injection molds for various components, meeting the strict requirements of safety and durability. For the medical field, our molds ensure the production of precise and hygienic plastic parts for medical devices.

Yigu Technology also boasts an advanced quality control system. We adhere to international standards like ISO 9001, ensuring that every injection mold we produce meets the highest quality criteria. From raw material inspection to in - process and final product checks, we leave no room for error. Our skilled workforce, trained in - house and through industry - recognized programs, is another key factor in our success. They are well - versed in the latest injection mold manufacturing techniques and can handle complex projects with ease.

In short, choosing Injection Mold China, especially with partners like Yigu Technology, means gaining access to cost - effective, high - quality molds, backed by rich experience and technical expertise.

FAQ

What are the common materials used in injection mold manufacturing in China?

In China, common materials for injection mold manufacturing include various types of steel and plastics. For steel, P20 steel is widely used. It has good machinability and polishing properties, with a hardness of around 28 - 34 HRC. This makes it suitable for general - purpose injection molds, such as those for producing plastic toys and simple household plastic products. Another popular steel is 718 steel, which offers better strength and hardness (about 33 - 37 HRC) compared to P20. It is often used in molds for high - quality plastic products like automotive interior parts, where higher precision and surface finish are required.

When it comes to plastics, polyethylene (PE) is very common. Low - density polyethylene (LDPE) has good flexibility and transparency, with a density of about 0.91 - 0.94 g/cm³. It is used in products like plastic bags and food packaging films. High - density polyethylene (HDPE) is more rigid and has a higher density (around 0.94 - 0.97 g/cm³), making it suitable for items such as plastic containers and pipes. Polypropylene (PP) is also widely used. It has excellent chemical resistance and heat resistance, and can withstand temperatures up to around 130 - 150°C. PP is often used in the production of kitchenware, automotive parts, and medical devices.

How can I ensure the quality of injection molds ordered from China?

To ensure the quality of injection molds ordered from China, there are several effective methods. First, check if the manufacturer has relevant certifications. For example, ISO 9001 certification indicates that the manufacturer follows international - standard quality management systems, covering aspects from raw material procurement to production processes and product inspection.

Second, request samples. A reliable manufacturer should be able to provide samples of their previous work or a sample mold similar to what you need. Inspect the sample carefully for dimensional accuracy, surface finish, and functionality. You can use precision measuring tools or send the sample to a third - party inspection agency for a more in - depth assessment.

Third, conduct a factory visit if possible. During the visit, observe the production equipment, the working environment, and the quality control procedures on - site. Check if the factory has advanced machining centers, high - precision measuring instruments like coordinate measuring machines (CMMs), and a well - organized quality control department.

What is the typical lead time for injection mold production in China?

The typical lead time for injection mold production in China usually ranges from 20 to 60 days. However, this can be affected by several factors. The complexity of the mold is a major factor. A simple two - plate injection mold for a basic plastic product may take only 20 - 30 days to produce. In contrast, a complex multi - cavity mold with intricate internal structures, such as a mold for producing high - precision medical device components, can take 45 - 60 days or even longer.

The quantity of molds ordered also matters. If you order a large quantity, the manufacturer may need more time to produce them all. For instance, an order of 100 identical simple molds may take longer than a single - mold order due to the need for batch production and quality control for each unit. Additionally, the availability of raw materials can impact the lead time. If there is a shortage of a particular type of steel or other key materials, it may delay the production process.