Introduction

Significance of Injection Mold Surface Finish

In the realm of injection molding, the surface finish of the mold is nothing short of a linchpin. It holds sway over multiple crucial aspects of the final product, making it a focal point for manufacturers aiming for excellence.

Aesthetic Appeal

The surface finish is often the first thing a consumer notices about a plastic product. For products like consumer electronics, such as the sleek casings of smartphones or tablets, a mirror - like smooth surface finish on the injection - molded parts can enhance the product's visual appeal, making it more attractive in the highly competitive market. A study by a leading market research firm found that products with high - quality surface finishes were more likely to be chosen by consumers in blind product tests, with up to 70% of consumers preferring products with smoother, shinier surfaces over those with dull or rough finishes. This preference is also evident in the automotive industry, where the interiors, including dashboards and door panels, are expected to have a consistent, high - quality surface finish to convey a sense of luxury and quality.

Functional Performance

Beyond aesthetics, the surface finish plays a vital role in the product's functionality. In applications where parts need to slide against each other, like in mechanical components or medical devices, a smooth injection mold surface finish reduces friction. For example, in a syringe, the plunger needs to move smoothly within the barrel. If the surface finish of the injection - molded barrel is rough, it can cause inconsistent dosing and may even damage the syringe during use. In addition, a proper surface finish can improve the sealing properties of products. In containers for food or chemicals, a smooth surface ensures a better seal, preventing leakage and extending the product's shelf - life.

Impact on Manufacturing and Cost

The surface finish of the injection mold also has implications for the manufacturing process. A well - finished mold can lead to easier demolding of the parts. When the mold surface is smooth, the plastic parts are less likely to stick to the mold, reducing the risk of part deformation or damage during demolding. This, in turn, can increase production efficiency. On the contrary, a rough mold surface may require more force to eject the parts, which can lead to higher energy consumption and potential tool wear. Moreover, a poor surface finish can result in a higher number of defective products, increasing production costs due to rework or scrap.

Process - Related Factors

Injection Parameters

Injection Pressure

Injection pressure is a critical parameter in the injection molding process. When the molten plastic is injected into the mold cavity, the injection pressure determines how quickly and effectively the plastic fills the mold. Insufficient injection pressure can lead to incomplete filling of the mold cavity. For example, in the production of complex - shaped plastic parts with thin - walled sections, if the injection pressure is too low, the plastic may not reach all the corners of the mold, resulting in short - shots. Short - shots are a major defect where the part is not fully formed, and this not only affects the appearance but also the functionality of the product.

On the other hand, excessive injection pressure can also cause problems. High injection pressures can lead to flash, which is the thin, excess material that forms around the edges of the mold due to the plastic being forced out between the mold halves. Flash not only requires additional trimming during post - processing but can also indicate that the mold's clamping force is not sufficient to withstand the high injection pressure. Moreover, high injection pressure can cause excessive stress on the plastic, leading to warping or cracking of the final product. A study on injection - molded plastic parts showed that an increase in injection pressure by 20% beyond the optimal level led to a 30% increase in the incidence of warping defects.

Injection Speed

Injection speed refers to how fast the molten plastic is injected into the mold cavity. A slow injection speed can cause the plastic to cool down prematurely as it flows through the mold, resulting in a non - uniform surface finish. When the plastic cools too quickly, it can lead to the formation of flow marks. Flow marks are visible lines or patterns on the surface of the plastic part that are caused by the non - uniform flow of the plastic. For instance, in the production of plastic automotive interior parts, slow injection speeds can create flow marks that are highly visible and reduce the aesthetic appeal of the product.

Conversely, an overly fast injection speed can cause air entrapment in the mold. As the plastic rushes into the mold cavity at a high speed, it can trap air pockets within the plastic. These air pockets can appear as voids or bubbles on the surface of the finished product, which not only affects the surface finish but also weakens the mechanical properties of the part. In some cases, high - speed injection can also cause jetting, where the plastic squirts into the mold cavity in a non - uniform manner, creating a poor - quality surface finish. A well - balanced injection speed, adjusted according to the plastic material, mold design, and part geometry, is crucial for achieving a high - quality surface finish.

Temperature Conditions

Melt Temperature

The melt temperature of the plastic material has a profound impact on the injection molding process and the resulting surface finish. When the plastic is heated to its melting point, it becomes a viscous fluid that can be injected into the mold. A proper melt temperature ensures good flowability of the plastic. If the melt temperature is too low, the plastic will have a high viscosity, making it difficult for it to flow smoothly within the mold cavity. This can lead to issues such as incomplete filling, flow marks, and a rough surface finish. For example, when molding polypropylene, if the melt temperature is set 20°C lower than the recommended value, the flowability of the plastic decreases significantly, and the surface of the final product may have visible flow lines and a matte appearance instead of the desired smooth and glossy finish.

On the contrary, if the melt temperature is too high, the plastic may degrade. Degradation can cause discoloration, a change in the chemical properties of the plastic, and a reduction in its mechanical strength. In addition, over - heated plastic may produce volatile by - products that can create surface defects such as pits or bubbles. For engineering plastics like polycarbonate, maintaining the melt temperature within a narrow range (usually ±5°C of the recommended value) is essential to ensure a high - quality surface finish and the overall integrity of the product.

Mold Temperature

Mold temperature is another crucial factor in determining the surface finish of injection - molded parts. A low mold temperature causes the plastic to cool down rapidly as it comes into contact with the mold walls. This quick cooling can lead to uneven shrinkage of the plastic, resulting in warping and a poor surface finish. For example, in the production of large - sized plastic panels, if the mold temperature is set too low, the panel may warp during the cooling process, and the surface may have visible ripples or unevenness.

A high mold temperature, on the other hand, allows the plastic to cool more slowly and evenly. This promotes better molecular orientation and reduces the internal stress within the plastic, resulting in a more uniform surface finish. In some cases, a higher mold temperature can also enhance the replication of the mold surface texture onto the plastic part. For products that require a high - gloss finish, such as cosmetic packaging, maintaining a relatively high mold temperature (e.g., 80 - 100°C for certain plastics) can help achieve a smooth, mirror - like surface. A comparison study showed that when molding the same plastic part, with a mold temperature of 40°C, the surface roughness was measured at 0.8μm, while at a mold temperature of 80°C, the surface roughness decreased to 0.3μm, indicating a significantly better surface finish at the higher mold temperature.

Cooling Process

Cooling Rate

The cooling rate of the injection - molded part is a key factor that affects its surface finish and dimensional stability. An uneven cooling rate can cause differential shrinkage within the plastic part. When different areas of the part cool at different speeds, internal stresses are generated. These internal stresses can lead to warping, where the part deviates from its intended shape. For example, in the production of rectangular plastic boxes, if one side of the box cools much faster than the other sides, the box may warp, with the sides becoming curved instead of straight.

In addition to warping, an uneven cooling rate can also cause surface defects such as sink marks. Sink marks are small depressions on the surface of the plastic part that occur when the material beneath the surface shrinks more than the outer layer. This is often due to areas with thick - walled sections cooling more slowly than thinner areas. For instance, in a plastic part with a ribbed structure, the ribs, which are usually thicker, may cool more slowly than the surrounding thinner walls. If the cooling rate is not properly controlled, sink marks may appear on the surface above the ribs, degrading the surface quality of the product.

Cooling Channel Design

The design of the cooling channels within the mold is crucial for ensuring a uniform cooling rate and, consequently, a good surface finish. A well - designed cooling channel system should provide even heat dissipation throughout the mold. Cooling channels that are too far apart or have an irregular layout can result in uneven cooling. For example, if the cooling channels in a mold are spaced too widely in one area, the plastic in that area will cool more slowly than in areas with closer - spaced cooling channels, leading to differential shrinkage and surface defects.

The diameter and shape of the cooling channels also play a role. Larger - diameter cooling channels can carry more coolant, which can enhance heat transfer. However, if the channels are too large, it may be difficult to achieve a uniform temperature distribution within the mold. Additionally, the shape of the cooling channels can affect the flow of the coolant. Straight - line cooling channels are easier to manufacture but may not provide the best heat - transfer efficiency in complex - shaped molds. In such cases, conformal cooling channels, which are designed to follow the shape of the mold cavity, can offer better heat - transfer performance. Conformal cooling channels can reduce the cooling time by up to 30% compared to traditional cooling channels, resulting in a more uniform cooling rate and a higher - quality surface finish.

Post - Processing Factors

Polishing

Types of Polishing Methods

- Mechanical Polishing: This is one of the most common methods. It involves the use of mechanical devices such as polishing machines, sanders, and buffing wheels. Mechanical polishing is highly effective in removing surface roughness, scratches, and tool marks. For example, in the production of large - scale plastic moldings like automotive bumpers, mechanical polishing with a series of abrasive belts of different grits can gradually smooth the mold surface. Coarse - grit abrasive belts are first used to remove significant surface imperfections, and then finer - grit belts are employed to achieve a smoother finish. It is suitable for molds with large surface areas and relatively simple shapes, as it can quickly improve the surface smoothness.

- Chemical Polishing: Chemical polishing uses chemical solutions to dissolve the surface layer of the mold in a controlled manner. This method is ideal for molds with complex geometries where mechanical polishing may be difficult to reach all areas. For instance, in the production of injection molds for small, intricate plastic parts with internal cavities and undercuts, chemical polishing can ensure that all surfaces are evenly polished. The chemical reaction selectively removes the high - points on the surface, resulting in a smooth and uniform finish. However, it requires careful handling of chemicals to ensure safety and environmental compliance.

- Electrolytic Polishing: Based on electrolysis principles, in electrolytic polishing, the mold is made the anode in an electrolyte solution. When an electric current is passed through, the metal on the mold surface is selectively dissolved, leading to a smooth and shiny surface. This method is often used for molds made of metals such as steel. It can achieve a very high - quality surface finish, with a mirror - like appearance in some cases. For precision molds used in the optical or electronics industry, where a flawless surface is crucial, electrolytic polishing can meet the stringent requirements.

Polishing Parameters and Their Influence

- Polishing Tools: The choice of polishing tools has a significant impact on the surface finish. For mechanical polishing, abrasive belts or polishing pads with different grit sizes are used at different stages. Coarse - grit polishing tools, such as 80 - 120 grit abrasive belts, are used in the initial stages to quickly remove rough surface layers. As the polishing progresses, finer - grit tools, like 800 - 1200 grit polishing pads, are used to achieve a smoother finish. In chemical polishing, the type of chemical solution used is crucial. Different chemical formulations are designed for specific mold materials to ensure effective and even polishing.

- Polishing Time: The duration of polishing also affects the surface finish. Insufficient polishing time may leave behind surface imperfections, while excessive polishing can lead to over - polishing, which may cause surface damage or dimensional changes. For example, in the polishing of a medium - sized plastic injection mold, a proper polishing time of about 2 - 4 hours may be required using mechanical polishing methods to achieve a satisfactory surface finish. If the polishing time is reduced to 1 hour, the surface may still have visible scratches, and if it is extended to 8 hours, the mold surface may become overly thin in some areas.

Coating

Types of Coatings

- Chrome Plating: Chrome plating is a popular coating for injection molds. It provides a hard, smooth, and corrosion - resistant surface. The high hardness of the chrome layer helps to prevent wear and tear during the injection molding process. For example, in molds used for producing plastic parts that require frequent mold - part interactions, such as those in high - volume production of plastic closures, chrome - plated molds can maintain their surface integrity for a longer time. The smooth surface of the chrome - plated mold also facilitates easy demolding of the plastic parts, reducing the risk of part damage.

- Nitriding: Nitriding is a process where nitrogen is diffused into the surface of the mold material, usually steel. This forms a hard nitride layer on the surface. Nitrided molds have improved wear resistance, fatigue resistance, and corrosion resistance. In the production of molds for engineering plastic components, such as those made of polyamide, nitriding can enhance the mold's performance. The nitride layer can withstand the high pressures and temperatures during the injection molding of engineering plastics, ensuring a long - lasting and high - quality surface finish for the mold.

Coating Application Process and Impact

- Coating Application Process: For chrome plating, the mold is first thoroughly cleaned and pre - treated to ensure good adhesion of the chrome layer. Then, it is immersed in a chromic acid - based electrolyte solution, and an electric current is applied to deposit the chrome onto the mold surface. The thickness of the chrome layer can be controlled by adjusting the plating time and current density. In the case of nitriding, the mold is heated in a nitrogen - rich environment, either in a gas - phase, liquid - phase, or plasma - phase process. The temperature, time, and nitrogen concentration are carefully controlled to achieve the desired depth and properties of the nitride layer.

- Impact on Injection Product Surface Quality: A well - applied coating can have a long - term positive impact on the surface quality of injection - molded products. A chrome - plated mold can transfer its smooth surface to the plastic parts, resulting in a high - gloss finish. Over time, the corrosion - resistant property of the chrome layer ensures that the mold surface remains in good condition, continuously producing parts with consistent surface quality. Nitrided molds, due to their enhanced wear resistance, can maintain the precision of the mold cavity, ensuring that the plastic parts have accurate dimensions and a smooth surface finish throughout the mold's lifespan. If the coating application is improper, such as uneven chrome plating or insufficient nitriding depth, it can lead to surface defects on the plastic parts, such as streaks or uneven gloss.

Yigu Technology's Perspective

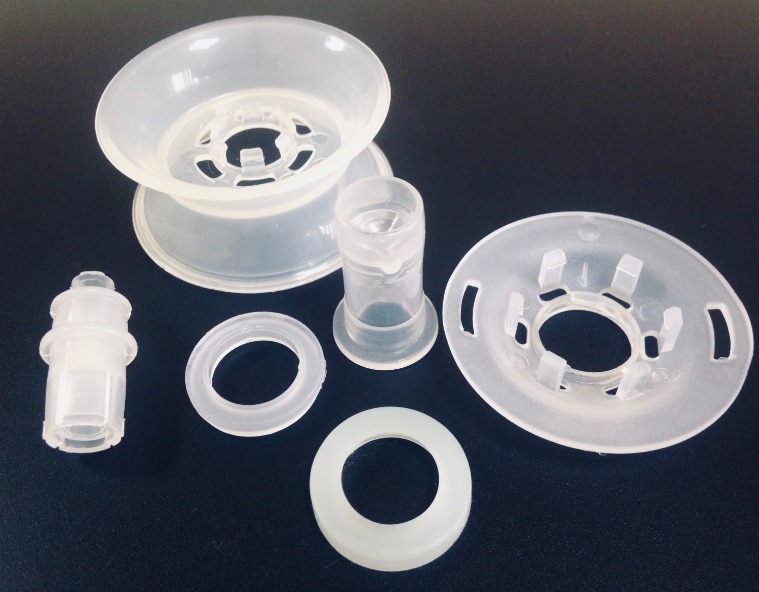

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in dealing with injection mold surface finish. When choosing materials, we are extremely cautious. We carefully analyze the characteristics of different plastic and mold materials, and select the most suitable ones according to the product requirements. For example, for products that require high - gloss surface finishes, we prefer plastics with good flowability and molds with high - hardness and smooth - surface materials.

In terms of process control, we have a strict set of operating procedures. Our technicians are trained to precisely control injection parameters such as pressure and speed, and maintain appropriate temperature conditions during the injection molding process. We also pay great attention to the cooling process, with optimized cooling channel designs to ensure a uniform cooling rate.

Moreover, in mold design, we take into account factors that may affect the surface finish, such as the layout of the cavity and the position of the gate. By integrating these aspects, we are committed to providing customers with high - quality injection - molded products with excellent surface finishes.

FAQ

Q1: How can I choose the right plastic material to ensure good injection mold surface finish?

When choosing a plastic material, consider the product's requirements. For products demanding high - gloss surfaces, select materials with low viscosity and good flowability, like some grades of polyethylene. If the product has complex shapes, materials with balanced viscosity are better to ensure complete filling of the mold cavity without causing defects. Also, check the moisture - absorption characteristics of the plastic. Materials with low moisture - absorption rates are preferred as excessive moisture can lead to surface defects like bubbles and silver - streaks.

Q2: What are the common surface defects caused by improper injection parameters?

Improper injection parameters can cause various surface defects. High injection pressure may lead to flash (excess material around the mold edges), and it can also cause the plastic to over - pack, resulting in warping or cracking. An overly fast injection speed can cause jetting, where the plastic squirts unevenly into the mold, creating a poor - quality surface. Additionally, it can trap air in the mold, leading to voids or bubbles on the product surface. Slow injection speed may cause the plastic to cool prematurely, forming flow marks on the surface.

Q3: Is it necessary to perform post - processing for injection molds to achieve a good surface finish?

For products with high - end surface quality requirements, post - processing is often necessary. Polishing can remove surface roughness, scratches, and tool marks, significantly improving the surface smoothness. Coating, such as chrome plating or nitriding, not only enhances the surface finish but also provides additional properties like wear resistance and corrosion resistance. However, for products with lower surface - finish requirements, post - processing may not be essential, as it adds to the production cost and time.