Introduction to PVC Pellets Injection Molding

In the vast landscape of modern manufacturing, PVC pellets injection molding stands as a cornerstone technology. PVC, short for Polyvinyl Chloride, is one of the most widely used thermoplastic materials globally. Its versatility, cost - effectiveness, and a range of remarkable properties make PVC pellets injection molding an indispensable process in countless industries.

PVC pellets are the raw materials for this molding process. These small, uniform pellets are composed of PVC resin, along with various additives such as stabilizers, plasticizers, and colorants. The injection molding process involves melting these pellets and injecting the molten material into a mold cavity under high pressure. Once inside the mold, the material cools and solidifies, taking on the precise shape of the mold cavity.

This article aims to comprehensively explore the shaping process, unique properties, and diverse applications of PVC pellets injection molding. Whether you are an engineer looking to optimize your manufacturing processes, a product designer seeking the right material for your next project, or a business owner interested in expanding your product line, understanding the ins and outs of PVC pellets injection molding is crucial.

The Injection Molding Process of PVC Pellets

1. Raw Material Preparation

Before the injection molding process begins, proper raw material preparation is crucial. PVC pellets often contain moisture, which can cause defects in the final product, such as bubbles or surface imperfections. Therefore, drying is a necessary step. One common method is to use a hot air dryer. The PVC pellets are placed in the dryer, and hot air with a temperature typically around 80 - 100°C is circulated around them. This temperature range is carefully selected because it can effectively remove moisture without causing premature degradation of the PVC. The drying time usually lasts for about 2 - 4 hours, depending on the initial moisture content of the pellets and the quantity being processed. Additionally, if the PVC pellets are going to be used to produce colored products, colorants are added at this stage. These colorants are thoroughly mixed with the PVC pellets to ensure a uniform color distribution throughout the final product.

2. Heating and Melting

Once the PVC pellets are properly prepared, they are fed into the injection molding machine's hopper and then enter the heating barrel. Inside the barrel, there are heating elements that gradually raise the temperature of the PVC pellets. The melting temperature of PVC typically ranges from 160 - 200°C. However, this temperature can be affected by several factors. For instance, the type of PVC resin used plays a significant role. Different grades of PVC resin may have slightly different melting points. Also, the presence of additives like plasticizers can lower the melting temperature. Plasticizers increase the flexibility of PVC, and in the process, they also reduce the energy required to melt the resin. The heating process is not only about reaching the melting point but also ensuring that the PVC is uniformly melted. The rotation of the screw inside the barrel helps in this process by continuously mixing and transporting the pellets, ensuring that all parts of the PVC reach the appropriate molten state.

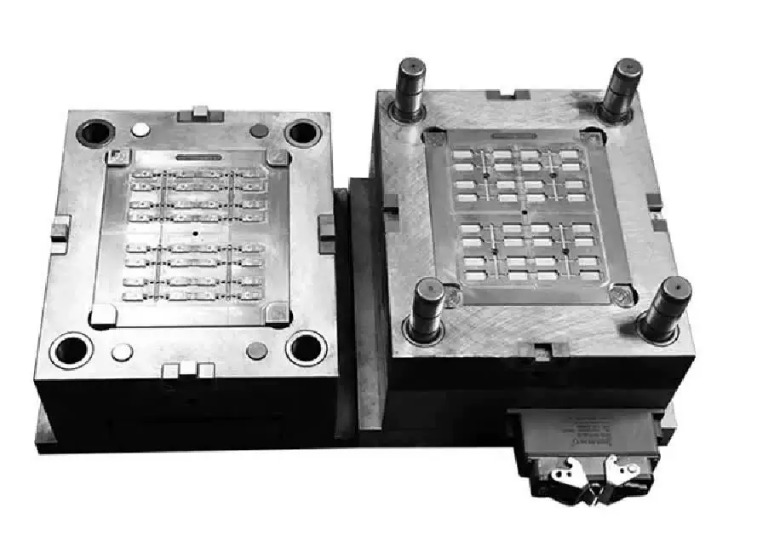

3. Injection into the Mold

When the PVC is fully melted and has the right viscosity, it is ready to be injected into the mold. A high - pressure injection system, usually powered by a hydraulic or electric mechanism, forces the molten PVC into the mold cavity. The injection pressure is a critical parameter. For PVC injection molding, the injection pressure can range from 50 - 150 MPa. A higher injection pressure may be required for complex - shaped molds or when the mold has long flow paths, as it ensures that the molten PVC can fill all the corners of the mold cavity completely. The injection speed also matters. A too - slow injection speed may lead to incomplete filling, while a too - fast speed can cause air entrapment or surface defects due to the rapid flow of the molten material. The injection time is another factor to consider, which is usually in the range of 1 - 10 seconds, depending on the size and complexity of the mold.

4. Cooling and Solidification

After the molten PVC is injected into the mold, it starts to cool and solidify. The mold is designed with a cooling system, typically using water channels. Cold water circulates through these channels, absorbing the heat from the molten PVC. The rate of cooling affects the quality of the final product. A slow cooling rate can lead to larger crystal formations in the PVC, which may result in a product with reduced mechanical properties and a less - smooth surface. On the other hand, overly rapid cooling can cause internal stress within the product, leading to warping or cracking. The ideal cooling time varies based on the thickness of the product. For a thin - walled PVC product, the cooling time may be as short as 5 - 10 seconds, while for a thick - walled one, it can be 30 seconds or more. The temperature of the cooling water also needs to be carefully controlled, usually maintained at around 15 - 25°C.

5. Ejection and Post - processing

Once the PVC has solidified sufficiently, the mold opens, and the 成型品 is ejected. Ejection is usually achieved through a mechanical ejection system, such as ejector pins. These pins push the product out of the mold cavity. After ejection, post - processing steps are carried out. One common post - processing step is trimming, where any excess material, such as the runner and gate systems that were used to feed the molten PVC into the mold, is removed. This can be done using trimming machines or simple hand - held tools. Another important post - processing step is quality inspection. The products are visually inspected for any defects like cracks, holes, or uneven surfaces. Dimensional measurements are also taken to ensure that the product meets the required specifications. In some cases, surface treatments such as polishing or painting may be applied to enhance the appearance and functionality of the product.

Applications of PVC Pellets Injection Molding

1. In the Construction Industry

PVC pellets injection molding finds extensive applications in the construction industry. PVC pipes are one of the most common applications. They are used for both water supply and drainage systems. PVC pipes are highly resistant to corrosion from various chemicals and substances present in water, making them a reliable choice for long - term use. For example, in residential buildings, PVC water supply pipes can ensure a safe and stable water supply for many years. Their smooth inner surface also reduces frictional resistance, allowing for efficient water flow. The cost - effectiveness of PVC pipes is another advantage. Compared to metal pipes such as copper or steel, PVC pipes are much more affordable, which is a significant factor in large - scale construction projects.

Window and door accessories are also frequently made through PVC pellets injection molding. PVC window frames, for instance, offer excellent insulation properties. They can effectively reduce heat transfer between the interior and exterior of a building, contributing to energy savings. According to some studies, buildings with PVC window frames can reduce heating and cooling energy consumption by up to 30% compared to those with traditional wooden or metal frames. PVC door handles and hinges are durable and resistant to wear and tear, even when exposed to different weather conditions, which is crucial for the long - term functionality of doors in buildings.

2. In the Automotive Industry

In the automotive industry, PVC injection - molded parts play a vital role. Interior components are often made of PVC. For example, PVC is widely used in the production of dashboard covers. PVC dashboard covers are lightweight, which helps to reduce the overall weight of the vehicle, thereby improving fuel efficiency. They also have good heat - insulating properties, protecting the underlying components from the heat generated by the engine and the sun. Additionally, PVC can be easily molded into complex shapes, allowing for the creation of aesthetically pleasing and ergonomic dashboard designs.

Automotive bumpers are another application of PVC injection molding. PVC bumpers are known for their impact - absorbing capabilities. They can deform upon impact and then return to their original shape, protecting the vehicle's body and passengers from damage during minor collisions. Moreover, PVC bumpers are relatively inexpensive to produce compared to bumpers made of some other materials like metal or high - end composites. This cost - advantage makes them a popular choice for many automotive manufacturers, especially for mass - produced vehicles.

3. In the Consumer Goods Industry

The consumer goods industry benefits greatly from PVC pellets injection molding. Toys are a prime example. PVC is often used to make various toys due to its flexibility and color - fastness. Soft PVC toys, such as rubber ducks or action figures, are safe for children to play with as they are non - toxic and have a smooth surface. The ability to add vibrant colorants to PVC during the injection molding process allows toy manufacturers to create eye - catching and appealing toys. Additionally, PVC toys are durable and can withstand the rough handling that often comes with children's play.

Home furnishings also frequently incorporate PVC injection - molded parts. PVC - made shower curtains are waterproof, easy to clean, and available in a wide range of designs and colors. They are a cost - effective alternative to fabric shower curtains. PVC floor tiles are another popular home product. These tiles are highly durable, resistant to scratches and stains, and can mimic the appearance of more expensive materials like wood or stone. They are easy to install, making them a DIY - friendly option for homeowners looking to upgrade their flooring.

Yigu Technology's Perspective

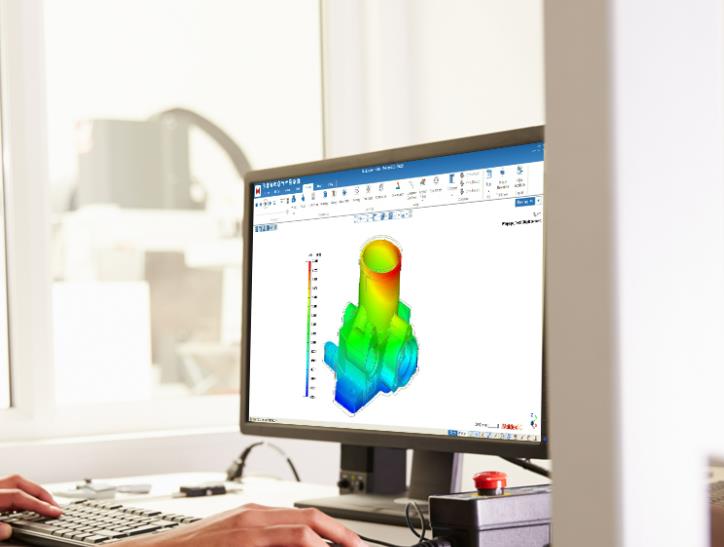

As a non - standard plastic metal custom products Supplier, Yigu Technology deeply understands the significance of PVC pellets injection molding. We place great emphasis on the careful selection of PVC materials. Different PVC resins and additives can lead to vast differences in the final product's quality and performance. For example, when producing products that require high flexibility, we select PVC resins with an appropriate amount of plasticizers to ensure the desired flexibility and flowability during the injection molding process.

In terms of the injection molding process, we have strict process control measures. Our professional engineers monitor and adjust key parameters such as temperature, pressure, and time in real - time. This ensures that each product meets the high - quality standards required by our customers. Whether it's a small - scale production for customized prototypes or large - scale mass production, we are committed to providing the best - quality non - standard plastic products, meeting the diverse needs of different industries and customers.

FAQ

1. What factors should be considered when choosing PVC pellets for injection molding?

When choosing PVC pellets, factors such as the type of resin (rigid or flexible), the content of additives like plasticizers and stabilizers, and the colorant requirements need to be considered. The intended application of the final product also plays a crucial role. For example, for products requiring high heat resistance, PVC pellets with appropriate heat - resistant additives should be selected.

2. How can we solve the problem of PVC product deformation after injection molding?

To solve the problem of product deformation, first, optimize the cooling system of the mold to ensure uniform cooling. Adjust the injection pressure and speed to avoid excessive internal stress. Also, consider the shrinkage rate of PVC and make appropriate adjustments in the mold design. For example, for products with a large area, adding reinforcement structures in the mold design can help reduce deformation.

3. Can recycled PVC pellets be used for injection molding?

Yes, recycled PVC pellets can be used for injection molding. However, their quality needs to be carefully evaluated. Recycled PVC may have issues such as inconsistent properties due to previous processing and contamination. Appropriate pretreatment, such as sorting, cleaning, and adding stabilizers, can improve the performance of recycled PVC pellets and make them suitable for injection molding in some applications.