Understanding Plastic Mold Casting Basics

What is Plastic Mold Casting?

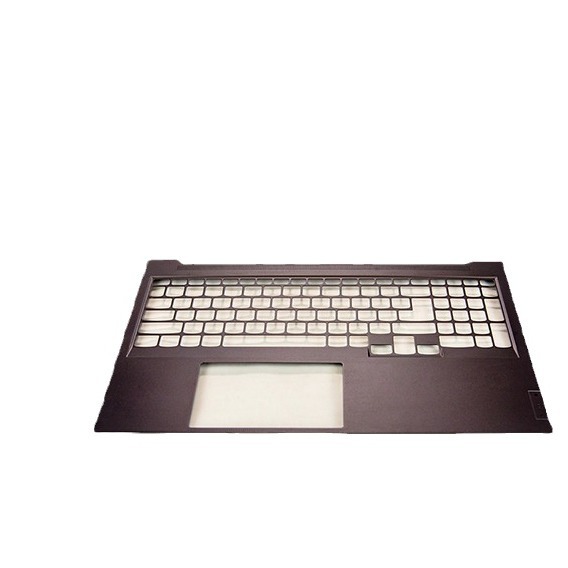

Plastic mold casting is a manufacturing process that has become the cornerstone of modern product development across numerous industries. At its core, it involves heating plastic materials until they reach a molten, fluid - like state. This melted plastic is then forcefully injected into a precisely designed mold cavity. The mold, which is typically made of steel or aluminum for its durability and heat - resistance, has a hollow interior that is shaped exactly like the desired final plastic product. Once the mold is filled with the molten plastic, it is allowed to cool. As the plastic cools, it solidifies, taking on the shape of the mold cavity. After the plastic has fully solidified, the mold is opened, and the newly formed plastic part is ejected. This process can be repeated thousands of times, depending on the quality of the mold, to produce large quantities of identical plastic products with high precision. For example, everyday items like plastic toy figures, smartphone cases, and food containers are often produced through plastic mold casting.

Key Components and Their Functions

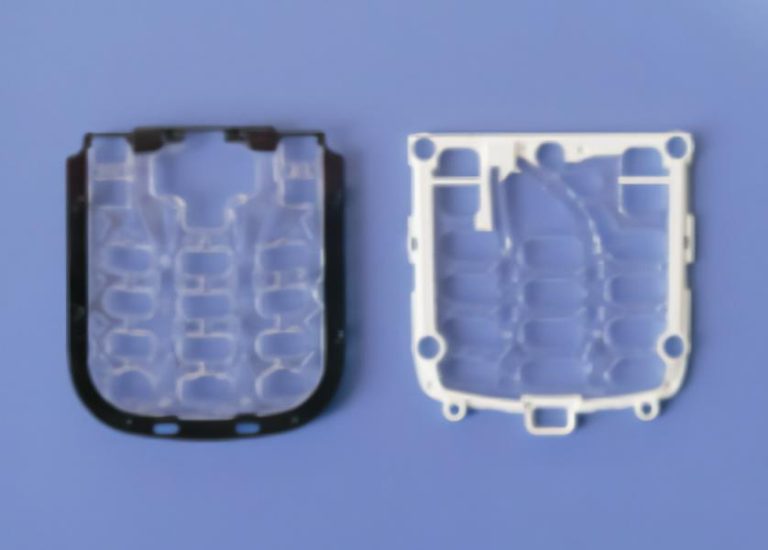

- Mold: The mold is the most crucial component. It consists of two main parts - the cavity and the core. The cavity determines the outer shape of the plastic part, while the core forms the internal features such as holes or recesses. Molds can be single - cavity (producing one part per cycle) or multi - cavity (producing multiple parts per cycle). For instance, a mold for producing small plastic bottle caps may have dozens of cavities, enabling high - volume production in a single injection cycle. High - quality molds are made from materials like hardened steel for long - term durability and to maintain tight tolerances, which is essential for producing parts with consistent quality.

- Injection Machine: This machine is responsible for melting the plastic pellets and injecting the molten plastic into the mold. It has a hopper where the plastic raw material (usually in pellet form) is loaded. Inside the machine, a heating barrel with a screw - type mechanism melts the plastic by applying heat and pressure as the screw rotates. The molten plastic is then forced through a nozzle and into the mold cavity under high pressure. Injection machines come in various sizes and capacities, with larger machines capable of handling high - volume production for large - scale industrial applications. For example, a large - scale automotive parts manufacturer may use a high - tonnage injection machine to produce large plastic components like bumpers.

- Cooling System: Efficient cooling is vital for the plastic to solidify quickly and evenly within the mold. The cooling system typically consists of channels drilled into the mold. A coolant, usually water or a water - based solution, circulates through these channels, absorbing the heat from the molten plastic. This rapid cooling not only reduces the cycle time (the time it takes to produce one part) but also ensures the dimensional stability of the final product. Without proper cooling, parts may have uneven shrinkage, leading to warping or other defects. For example, in the production of plastic pipes, a well - designed cooling system helps to maintain the straightness and uniform wall thickness of the pipes.

Real - World Examples of Creative Plastic Mold Casting

Consumer Products: Transforming Daily Life

In the realm of consumer products, plastic mold casting has been a game - changer, enabling the creation of items that are both functional and aesthetically pleasing.

- Creative Homeware: Consider modern, ergonomically designed kitchen utensils. A well - known brand of spatulas is produced through plastic mold casting. The molds are designed to create a non - slip grip, which is achieved by adding specific textures during the mold - making process. These textures are precisely replicated on the plastic spatulas, providing users with a secure hold while cooking. Moreover, the molds allow for the integration of colorful, translucent plastics, making the spatulas not only practical but also visually appealing in any kitchen.

- Fashion Accessories: Plastic mold casting has revolutionized the fashion industry. For instance, statement - making plastic jewelry pieces are crafted using this technique. Intricate designs, such as floral patterns or geometric shapes, can be easily replicated in plastic. A popular line of chunky plastic bracelets features detailed carvings that are made possible by the precision of plastic mold casting. These bracelets are not only lightweight but also available in a wide range of colors, allowing consumers to express their personal style. Additionally, plastic mold casting enables the mass - production of these accessories at a relatively low cost, making fashionable items accessible to a larger market.

Industrial Applications: Function Meets Form

- Aerospace: In the aerospace industry, plastic mold casting is used to produce lightweight yet durable components. For example, interior cabin components like overhead storage bins are made from high - strength plastic materials through mold casting. The molds are designed to meet strict aerodynamic and safety requirements. They ensure that the bins have smooth surfaces to reduce air resistance during flight and are strong enough to withstand the pressure and vibrations experienced in the aircraft. The use of plastic mold casting in aerospace not only reduces the overall weight of the aircraft, leading to fuel efficiency, but also allows for the creation of complex shapes that optimize space utilization within the cabin.

- Medical Devices: In the medical field, plastic mold casting plays a crucial role in manufacturing components for devices such as inhalers. The molds are engineered to create parts with extremely tight tolerances. The plastic components of an inhaler need to fit together precisely to ensure the accurate delivery of medication. Through plastic mold casting, manufacturers can produce parts like the mouthpiece and the medication reservoir with the required precision. The ability to use biocompatible plastic materials in mold casting also makes it suitable for medical applications, as these materials are safe for human contact and do not cause adverse reactions.

Yigu Technology's Perspective

As a leading non - standard plastic metal products custom supplier, Yigu Technology has witnessed firsthand the power of plastic mold casting in driving innovation. With years of experience in the field, we understand that every client has unique requirements, and plastic mold casting allows us to turn these specific needs into tangible, high - quality products.

We believe that plastic mold casting serves as a catalyst for creativity in product design. It enables us to work closely with our clients, from the initial concept stage to the final product launch. By leveraging the flexibility of plastic mold casting, we can create custom - designed molds that bring our clients' innovative ideas to life. Whether it's a complex - shaped component for an industrial device or a stylish consumer product, our expertise in plastic mold casting ensures that we can provide tailored solutions. This not only helps our clients stand out in the market but also encourages continuous innovation as we explore new materials and design possibilities together.

FAQ about Plastic Mold Casting

What are the common types of plastic mold casting?

There are several common types of plastic mold casting, each with its own characteristics. Injection molding is one of the most widely used methods. It involves injecting molten plastic into a closed mold cavity under high pressure. This process is suitable for producing a wide range of products, from small, intricate parts like electronic components to large, complex items such as automotive bumpers. The high - pressure injection ensures that the plastic fills the mold cavity quickly and accurately, resulting in high - precision parts with smooth surfaces.

Blow molding is another popular method, mainly used for producing hollow plastic products like plastic bottles, containers, and toys. In blow molding, a tube of molten plastic (parison) is placed inside a mold. Compressed air is then blown into the parison, forcing it to expand and take the shape of the mold cavity. This process allows for the creation of products with uniform wall thickness and good structural integrity.

Compression molding is often used for manufacturing products that require high - strength and heat - resistance, such as electrical insulators and automotive parts. In this process, pre - measured amounts of plastic material (usually in the form of a solid pellet or pre - formed shape) are placed in an open mold. The mold is then closed, and heat and pressure are applied. The plastic softens under the heat and pressure, filling the mold cavity and taking on the desired shape.

How to ensure the quality of plastic mold casting products?

Ensuring the quality of plastic mold casting products requires careful control of several factors. Temperature control is crucial. The temperature of the plastic during the melting and injection process must be precisely regulated. If the temperature is too low, the plastic may not flow properly into the mold cavity, resulting in incomplete parts or surface defects. On the other hand, if the temperature is too high, the plastic may degrade, leading to a loss of mechanical properties and discoloration.

Pressure management also plays a significant role. The injection pressure needs to be carefully adjusted to ensure that the molten plastic fills the mold completely without causing excessive stress on the mold or the part. Too little pressure can lead to voids or short - shots (incomplete filling), while too much pressure can cause flash (excess plastic around the edges) or part distortion.

Mold precision is essential. High - quality molds with tight tolerances are necessary to produce parts with consistent dimensions. Regular maintenance and inspection of the mold can help to detect and correct any signs of wear or damage promptly. Additionally, using high - quality mold materials, such as hardened steel, can improve the mold's durability and accuracy over time.

Can I customize the color of plastic mold casting products?

Yes, you can customize the color of plastic mold casting products. One common method is by adding color masterbatch to the plastic raw material. Color masterbatch is a concentrated mixture of pigments or dyes and a carrier resin. When added to the base plastic resin in the appropriate proportion, it can impart a specific color to the final product. There is a wide range of color masterbatches available, allowing for the creation of almost any color imaginable.

However, when choosing colors, there are some considerations. The type of plastic resin being used can affect the color appearance. Different plastics may have different levels of transparency or opacity, which can alter how the color is perceived. Also, the processing conditions, such as temperature and shear stress during the molding process, can impact the color stability. Some colors may be more sensitive to these conditions and may experience slight color changes during processing. It's advisable to conduct color trials before large - scale production to ensure the desired color is achieved and maintained consistently.