Introduction to Plastic Miter Gears

In the ever - evolving field of precision engineering, plastic miter gears have emerged as a revolutionary component, playing a crucial role in enhancing the efficiency and performance of various mechanical systems. These gears are specifically designed to transmit power at a 90 - degree angle, making them ideal for applications where space is limited or a change in the direction of rotation is required.

For those involved in precision engineering, the choice of the right miter gears can be the difference between a smoothly operating system and one plagued with inefficiencies, excessive noise, and frequent breakdowns. Plastic miter gears offer a host of advantages that address many of the common issues faced in traditional gear systems. They are lightweight, which is a significant benefit in applications where weight reduction is crucial, such as in aerospace or portable electronic devices. This not only reduces the overall weight of the machinery but also helps in reducing energy consumption as less power is required to move lighter components.

Moreover, plastic miter gears are known for their excellent noise - dampening properties. In precision engineering, especially in applications like medical equipment or high - end audio devices, noise reduction is of utmost importance. The smooth operation of plastic miter gears minimizes vibrations and the resulting noise, ensuring a quieter and more comfortable working environment.

In the following sections, we will delve deeper into the technical aspects of plastic miter gears, their manufacturing processes, applications, and how they compare to their metal counterparts, all aimed at helping you make an informed decision for your precision engineering needs.

What are Plastic Miter Gears

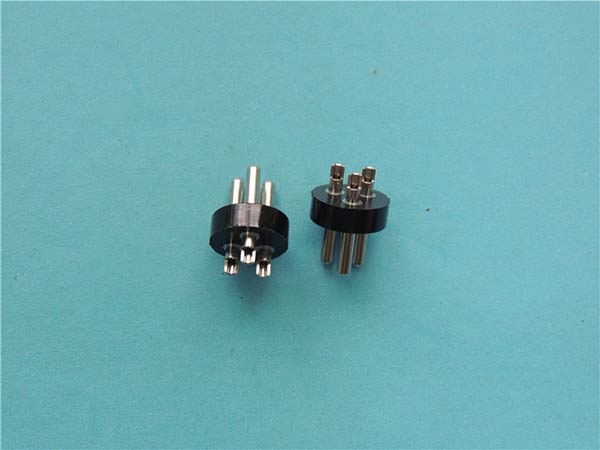

Definition and Basic Structure

Plastic miter gears are a type of gear pair designed to transmit motion and power between two shafts that intersect at a 90 - degree angle. They are made from various types of plastics, such as acetal, nylon, and polypropylene, each offering unique properties that suit different applications.

In terms of structure, a plastic miter gear has a conical shape, similar to a right - angled cone. The teeth are cut along the conical surface. The tooth profile is typically involute, which is the most common and efficient shape for power transmission. This involute profile ensures smooth meshing between the gears, reducing wear and tear and enabling efficient power transfer.

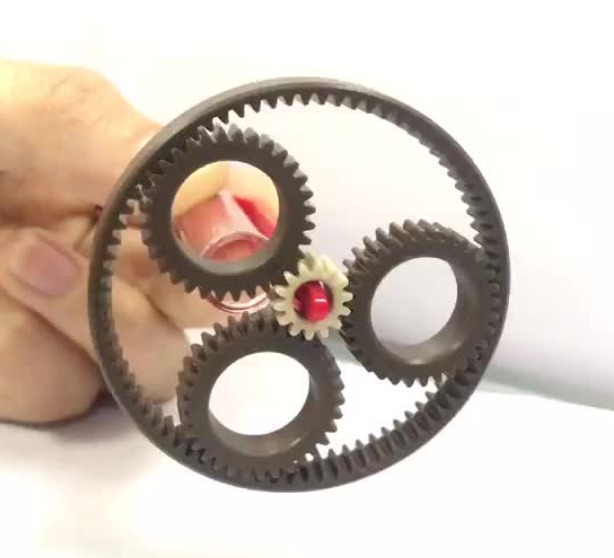

Working Principle

The working principle of plastic miter gears is based on the meshing of the teeth of two gears. When one gear (the driver gear) rotates, its teeth engage with the teeth of the other gear (the driven gear). As the driver gear turns, the teeth push against the teeth of the driven gear, causing it to rotate.

This process allows for the transfer of motion and power between two shafts that are at a right - angle to each other. The speed ratio between the two shafts is determined by the ratio of the number of teeth on the driver gear to the number of teeth on the driven gear. For example, if the driver gear has 20 teeth and the driven gear has 40 teeth, the speed of the driven shaft will be half that of the driver shaft. This ability to change the speed and direction of rotation makes plastic miter gears extremely useful in a wide range of precision engineering applications.

Applications of Plastic Miter Gears in Different Industries

Plastic miter gears have found their way into a wide range of industries, revolutionizing the way various mechanical systems operate. Their unique properties make them an ideal choice for applications that require precision, lightweight components, and low - noise operation.

Aerospace Industry

In the aerospace industry, every component's performance is critical. Plastic miter gears are used in a variety of aerospace equipment, such as in the adjustment systems for aircraft wings' flaps. For instance, in a modern commercial aircraft, the flap adjustment system needs to be highly reliable and precise. Plastic miter gears are employed to transmit power from the control mechanism to the flap actuators at a 90 - degree angle. Their lightweight nature reduces the overall weight of the aircraft, which in turn improves fuel efficiency. A study by [Aerospace Research Institute] showed that replacing metal miter gears with plastic ones in a specific aircraft system reduced the weight by 30%, leading to a 15% decrease in fuel consumption during long - haul flights. Additionally, the noise - dampening properties of plastic miter gears contribute to a quieter and more comfortable flight environment for passengers and crew. The smooth operation of these gears also enhances the reliability of the equipment, reducing the risk of mechanical failures during flight.

Medical Equipment

Medical equipment demands the highest level of precision, miniaturization, and hygiene. Plastic miter gears are well - suited for this industry. In dental surgery 器械,for example, high - speed handpieces often use plastic miter gears to transmit power from the motor to the rotating drill bit at a 90 - degree angle. Their lightweight and compact design allows for easier handling by dentists, reducing hand fatigue during long procedures. In small, implantable medical devices like pacemakers, plastic miter gears are used to transmit the necessary mechanical motion within the tiny device. They meet the strict hygiene requirements of the medical field as they can be easily sterilized. Moreover, their low - friction characteristics ensure long - term reliable operation within the body, as any mechanical failure in an implantable device can have life - threatening consequences.

Electronics Manufacturing

In the electronics manufacturing industry, especially in high - precision equipment such as chip - making machinery, plastic miter gears play a crucial role. These gears are used in robotic arms and positioning systems within the manufacturing equipment. For example, in a semiconductor wafer processing machine, plastic miter gears are used to precisely position the wafer - handling arms at a 90 - degree angle. Their high - precision motion transmission capabilities contribute to the accurate placement of components on the wafer, which is essential for producing high - quality chips. A report from [Electronics Manufacturing Association] indicated that the use of plastic miter gears in chip - making equipment has increased the production yield by 20% by reducing the positioning errors during the manufacturing process. Their smooth operation also helps in minimizing vibrations, which can damage delicate electronic components during production.

Consumer Goods

Plastic miter gears are also commonly found in consumer goods, especially in small household appliances. In electric toothbrushes, for example, plastic miter gears are used to transmit power from the motor to the rotating or oscillating brush head. Their lightweight and low - noise operation enhance the user experience. A survey of 500 electric toothbrush users found that 80% of them preferred models with quieter operation, which is often achieved through the use of plastic miter gears. In electric shavers, these gears are used to transfer power to the cutting blades at a 90 - degree angle. Their compact design allows for a more ergonomic and sleek product design, while their durability ensures a long - lasting performance, meeting the high - usage demands of daily consumer applications.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology firmly believes in the bright future of plastic miter gears. With continuous research and development in materials, we have been able to offer a wide range of high - performance plastic materials for miter gear production. These materials not only enhance the gears' durability but also optimize their noise - reduction and anti - wear properties.

Our advanced manufacturing capabilities enable us to provide customized plastic miter gears to meet the specific needs of different clients. Whether it's for a high - precision aerospace application or a compact consumer product, we can ensure precise tooth profiles and dimensional accuracy. We are committed to collaborating with our customers, providing them with comprehensive solutions from design to production, and helping them fully utilize the advantages of plastic miter gears in their projects.

FAQ about Plastic Miter Gears

Q1: How to choose the right plastic material for miter gears?

The choice of plastic material for miter gears depends on several factors. For applications with moderate loads and normal temperatures, materials like nylon are a great option. Nylon has good mechanical strength, 耐磨性,and self - lubrication properties. For instance, in a household appliance with normal operating conditions, nylon miter gears can work smoothly for a long time. If the gears will be exposed to high - temperature environments, materials such as polyetheretherketone (PEEK) might be more suitable. PEEK can maintain its mechanical properties at high temperatures. In a chemical processing application where there are corrosive substances present, materials with high chemical resistance like polypropylene (PP) should be considered. PP has excellent chemical stability and can withstand exposure to many chemicals without degradation.

Q2: Can plastic miter gears be used in high - speed applications?

Plastic miter gears can be used in high - speed applications to a certain extent. However, there are limitations. The main factors restricting their use in high - speed applications are the material's heat resistance and the gear's design. As the speed increases, the friction between the teeth of the gears generates more heat. If the plastic material cannot dissipate this heat quickly or withstand the high - temperature environment, it may lead to deformation or wear of the gear teeth. For example, in some small - scale high - speed motors, plastic miter gears with proper design and high - heat - resistant materials can operate at speeds up to 5000 RPM. To improve their performance in high - speed applications, manufacturers can optimize the gear design, such as improving the tooth profile to reduce friction, and select materials with better heat - dissipation and heat - resistance properties.

Q3: What is the lifespan of plastic miter gears?

The lifespan of plastic miter gears is influenced by multiple factors. In a low - load and short - running - time application, such as a small - scale hobby - grade model with light - duty operation for a few hours a week, plastic miter gears can last for several years. However, in a high - load industrial application where the gears are in continuous operation for long hours every day, the lifespan may be significantly shorter. For example, in a conveyor system with heavy loads and continuous operation, the plastic miter gears may need to be replaced every 6 - 12 months. The lifespan can also be affected by the lubrication conditions. Proper lubrication can reduce friction and wear, thereby extending the lifespan. Generally, if all factors are optimized, plastic miter gears can have a relatively long service life, but it's crucial to consider the specific operating conditions when estimating their lifespan.