Plastic & Metal industry knowledge

Transfer the value information of rapid prototypes, mold and injection molding industry

Injection Molding Thermoplastic Elastomer (TPE): A Complete Practical Guide

Introduction Thermoplastic Elastomer (TPE) has become a go-to material in modern manufacturing, blending the elasticity of rubber with the processability of plastics. Yet, many manufacturers face headaches when dealing with...

Injection Molding Thermoplastic Polyurethane (TPU): A Comprehensive Guide

Introduction Thermoplastic Polyurethane (TPU) has emerged as a highly versatile material in the manufacturing industry. However, working with TPU in injection molding comes with its own set of challenges. Manufacturers...

Injection Molding Elastomers & Flexible Materials: Mastering Elasticity and Precision

Elastomers and flexible materials are indispensable for applications requiring stretch, seal, or shock absorption, but molding them to maintain consistent elasticity and dimensional accuracy is a challenge. Many manufacturers struggle with achieving uniform Shore hardness across...

Injection Molding Polycarbonate (PC): Balancing Strength and Clarity

Polycarbonate (PC) is a versatile engineering plastic prized for its unique combination of high impact strength and optical clarity, but molding it to perfection presents distinct challenges. Even small variations...

Injection Molding Polymethyl Methacrylate (PMMA/Acrylic): Mastering Clarity and Durability

Polymethyl Methacrylate (PMMA), commonly known as acrylic, is prized for its exceptional transparency, but molding it to perfection comes with unique challenges. Even tiny flaws like micro-scratches or cloudiness can...

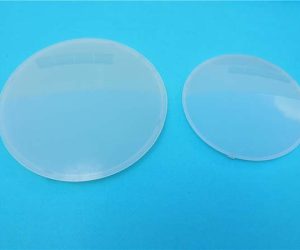

Injection Molding Transparent Plastics: Achieving Clarity and Precision in Every Part

Transparent plastics are indispensable in countless applications, but molding them to maintain flawless optical clarity is a challenge that frustrates many manufacturers. Even minor defects like micro-voids or surface scratches...

Injection Molding Polyphenylene Sulfide (PPS): Mastering High-Performance Thermoplastic

Polyphenylene Sulfide (PPS) is a high-performance plastic renowned for its resilience in extreme environments, but molding it presents unique challenges that can test even seasoned manufacturers. Its exceptional high-temperature resistance...

Injection Molding Polyetherimide (PEI/Ultem): Mastering High-Performance Engineering Plastic

Polyetherimide (PEI), commercially known as Ultem, is a high-performance plastic revered for its versatility, but molding it presents unique challenges that can test even experienced manufacturers. Its exceptional high-temperature resistance...

Injection Molding Polyetheretherketone (PEEK): Mastering Ultra-High-Performance Plastic

Polyetheretherketone (PEEK) stands at the pinnacle of high-performance plastics, but molding it presents unique challenges that can frustrate even experienced manufacturers. Its extreme high-temperature resistance demands specialized equipment, and even...

Injection Molding High-Performance Plastics: A Comprehensive Guide to Excellence

High-performance plastics are revolutionizing manufacturing, but working with them comes with unique challenges that can stump even seasoned professionals. Choosing the right material from the vast array of high-performance plastics...

Injection Molding Polyoxymethylene (POM/Acetal): Mastering High-Performance Engineering Plastic

Polyoxymethylene (POM/Acetal) is a go-to material for precision parts, but it comes with its own set of challenges that can frustrate manufacturers. Achieving consistent low friction properties across batches is...

Injection Molding Nylon (PA6, PA66): Mastering Versatile Engineering Plastics

Nylon (PA6, PA66) is a staple in injection molding, but it brings unique challenges that can trip up manufacturers. Its high moisture absorption is a constant headache—even slight exposure to...

Injection Molding Polycarbonate (PC): Unlocking Potential of a High-Performance Plastic

Polycarbonate (PC) is a sought-after material in injection molding, but it comes with its own set of challenges that can frustrate even experienced manufacturers. From struggling with maintaining its optical...

Injection Molding Acrylonitrile Butadiene Styrene (ABS): Mastering Versatile Engineering Plastic

Acrylonitrile Butadiene Styrene (ABS) is a go-to material in injection molding, yet many manufacturers grapple with its unique challenges. From parts that warp unexpectedly to surface defects ruining otherwise perfect...

Injection Molding Engineering Plastics: A Comprehensive Guide to Mastering the Process

Injection molding of engineering plastics is a cornerstone of modern manufacturing, yet it’s riddled with challenges that can derail production, inflate costs, and compromise part quality. From selecting the wrong...

Injection Molding Polyethylene (PE) – LDPE/HDPE: A Comprehensive Guide

Introduction Polyethylene (PE) is one of the most widely used plastics in injection molding, but working with Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) comes with distinct challenges. Manufacturers often...

Injection Molding High-Impact Polystyrene (HIPS): Process, Design, Troubleshooting

Introduction High-Impact Polystyrene (HIPS) is a go-to material for parts needing both affordability and toughness, but molding it comes with unique challenges. Manufacturers often struggle with balancing impact strength and...

Injection Molding Polystyrene (PS): Mastering Process, Materials, Mold Design

Introduction Polystyrene (PS) is a go-to material in injection molding for its versatility and cost-effectiveness, but it comes with its own set of challenges. Manufacturers often grapple with issues like...

Injection Molding Polypropylene (PP): A Complete Guide for Manufacturers

Introduction Polypropylene (PP) is one of the most widely used plastics in injection molding, but working with it isn’t without challenges. Manufacturers often struggle with issues like warping during cooling,...

Injection Molding Plastics: A Comprehensive Guide to Material, Process, and Quality

Introduction Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. However, it comes with its fair share of challenges. From choosing the...