Understanding the Basics of Injection Molding

What is Injection Molding?

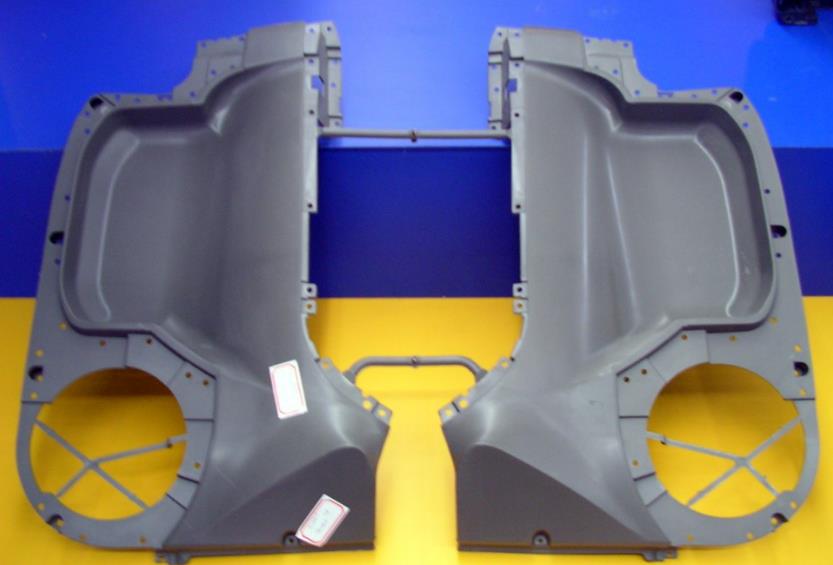

Injection molding is a widely used manufacturing process for producing parts by injecting molten material, most commonly plastic, into a mold. The process begins with plastic pellets being fed into a heated barrel. Here, they are melted into a viscous liquid state. A screw or plunger then forces this molten plastic under high pressure into a precisely designed mold cavity. The mold, usually made of steel or aluminum, is cooled to solidify the plastic quickly, taking on the exact shape of the mold interior. Once solidified, the mold opens, and the finished part, now a hardened plastic component, is ejected. This method is highly efficient for creating complex, high - precision, and mass - produced plastic items. For example, in the production of smartphone cases, injection molding allows for the rapid creation of thousands of identical cases with intricate details like button cutouts and speaker grilles.

Importance of Choosing the Right Company

Selecting the appropriate injection molding service company has far - reaching impacts on various aspects of a project:

- Product Quality: A skilled injection molding company will have a deep understanding of different materials and how to optimize the molding process for each. They can ensure that the final product has consistent wall thickness, smooth surfaces, and no internal defects. For instance, a company with advanced quality control measures can detect and correct issues like air bubbles or warping during the production of medical device components, which is crucial for the safety and effectiveness of the final product.

- Cost - Efficiency: An experienced injection molding service provider can help minimize costs. They can optimize the design to reduce material waste, choose the most cost - effective materials without sacrificing quality, and efficiently manage production schedules to avoid unnecessary overtime or machine downtime. A well - run company might use a runner - less mold system, which reduces the amount of wasted plastic in the runner channels, leading to significant cost savings over time.

- Production Efficiency: The right company will have up - to - date equipment and efficient production processes. High - speed injection molding machines can produce parts in a shorter cycle time, and automated post - processing steps can further speed up the overall production. In the automotive industry, where large volumes of parts like interior trim pieces are needed, a company with efficient production capabilities can meet tight deadlines and high - volume demands without compromising on quality.

Key Factors to Consider

Experience and Expertise

Years in the Industry

The number of years an injection molding service company has been in business is a strong indicator of its reliability. A company with a long - standing presence, say 10 years or more, has had the opportunity to weather various market challenges and technological shifts. For example, such a company is likely to have encountered a wide range of material - related issues during the injection molding process. Over time, they have developed tried - and - true solutions to problems like material degradation during high - temperature injection or issues with material flow in complex mold geometries. This accumulated knowledge allows them to handle projects more efficiently and with fewer errors. Newer companies may still be in the learning phase, which could potentially lead to longer lead times and more trial - and - error during the production process.

Range of Projects Handled

A company that has experience in handling a diverse range of projects is better equipped to meet different customer needs. Consider a company that has worked on projects for the automotive, medical, and consumer electronics industries. In the automotive industry, parts often require high - strength materials and strict dimensional tolerances to ensure safety and proper functionality. For instance, engine components need to withstand high temperatures and mechanical stress. In the medical field, products must meet strict biocompatibility standards, and precision is crucial, especially for items like syringe components. In consumer electronics, aesthetics and miniaturization are important factors, such as the sleek and precisely - fitting cases for smartphones. A company with this breadth of experience can draw on its past knowledge to quickly adapt to new projects, regardless of the industry requirements.

Quality Assurance

Certifications

Certifications are a clear sign of a company's commitment to quality. One of the most well - known certifications in the manufacturing industry is ISO 9001. This certification demonstrates that a company has a well - defined quality management system in place. It covers aspects such as how the company manages customer requirements, controls its production processes, and ensures continuous improvement. For injection molding service companies, ISO 9001 compliance means that they have strict procedures for material inspection before production, regular equipment maintenance to ensure consistent performance, and a system for tracking and resolving any quality issues that arise. Other relevant certifications might include ISO 13485 for companies producing medical - related injection - molded parts, which specifically addresses the quality management requirements for medical devices.

In - house Quality Control Processes

A reliable injection molding service company will have robust in - house quality control processes. This typically starts with incoming material inspection. The company will use various testing methods, such as density testing and melt flow index testing for plastic materials, to ensure that the raw materials meet the required specifications. During the production process, they will conduct regular in - line inspections. For example, they may use optical measuring devices to check the dimensions of the molded parts at regular intervals. After production, a final inspection is carried out. This could involve using 3D scanning technology to compare the final product with the original design model, ensuring that all features are within the specified tolerances. Some companies also have a quality control laboratory where they can perform more in - depth tests, such as fatigue testing for parts that will be subject to repeated stress.

Equipment and Technology

Modern Machinery

Advanced injection molding machines play a crucial role in the quality and efficiency of production. High - precision injection molding machines can achieve extremely tight tolerances, often within ±0.01mm or even less. This is essential for industries like aerospace, where even the slightest deviation in part dimensions can have serious consequences. These modern machines also tend to be more energy - efficient, which not only reduces the company's operating costs but also aligns with environmental sustainability goals. Additionally, they have faster cycle times. For example, a state - of - the - art machine might be able to complete a molding cycle in 10 - 15 seconds for simple parts, compared to 20 - 30 seconds for older models, greatly increasing production output.

Use of CAD/CAM Technology

CAD (Computer - Aided Design) and CAM (Computer - Aided Manufacturing) technology has revolutionized the injection molding process. In the design phase, CAD allows engineers to create highly detailed 3D models of the parts and molds. This enables them to identify and resolve potential design issues, such as poor material flow paths or areas of high stress concentration, before the physical production begins. For example, through CAD software, designers can perform flow analysis simulations to ensure that the molten plastic will evenly fill the mold cavity. CAM technology then takes over in the manufacturing stage. It converts the design data into machine - readable instructions for the injection molding machines and other manufacturing equipment, such as CNC (Computer Numerical Control) machines used for mold making. This automation reduces human error and ensures high - precision manufacturing, resulting in parts that closely match the original design.

Cost - effectiveness

Pricing Structure

Injection molding service companies may have different pricing structures. Some charge on a per - piece basis, which is straightforward for projects where the quantity of parts is the main factor. For example, if a customer needs 10,000 simple plastic brackets, the cost per bracket can be easily calculated based on material costs, machine time, and a profit margin. Other companies may use a per - project pricing model, which is more suitable for complex projects that involve multiple parts, custom tooling, and additional services. This model takes into account all the aspects of the project, including design assistance, prototyping, and production. Understanding these pricing structures helps customers accurately estimate their costs and choose the most cost - effective option for their specific needs.

Hidden Costs

It's important for customers to be aware of potential hidden costs. One common hidden cost is mold maintenance. Molds used in injection molding can wear out over time, especially with high - volume production. The cost of regular mold maintenance, including cleaning, polishing, and repair, should be factored into the overall cost. Another hidden cost could be transportation. If the customer requires the parts to be shipped to a specific location, the shipping fees, especially for large or heavy orders, can add up significantly. Some companies may also charge for additional services like packaging customization, which should be clarified upfront to avoid unexpected expenses.

Customer Service

Responsiveness

A company's responsiveness to customer inquiries and issues is crucial. For example, if a customer has an urgent question about the progress of their order, a good injection molding service company will reply to their email or phone call within a few hours. In cases where there are production delays or quality issues, the company should communicate promptly with the customer and provide solutions. Consider a situation where a customer needs a small batch of parts for an upcoming product launch. If the injection molding company notices a problem with the mold during production, they should inform the customer immediately and offer options such as expediting mold repairs or providing a temporary workaround to meet the launch deadline.

After - sales Support

After - sales support is an important aspect of a company's customer service. This can include product repair or replacement in case of defects. A reliable company will have a clear policy on handling such issues. For example, if a customer discovers that some of the injection - molded parts are cracked or have other defects within a certain warranty period, the company should arrange for the defective parts to be replaced at no additional cost. Good after - sales support also includes providing technical advice on how to use and maintain the products. This long - term support helps build trust between the customer and the company and ensures the customer's continued satisfaction.

Yigu Technology's Insights

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the significance of choosing the right injection molding service companies. With years of experience in the field, we emphasize several key points.

Firstly, our rich experience enables us to handle complex projects with ease. We have dealt with a wide variety of materials and product requirements, allowing us to offer practical solutions to our customers. For example, when handling projects with high - temperature - resistant materials for aerospace - related parts, our in - depth knowledge ensures the successful completion of the molding process.

Secondly, in terms of technology, we keep up with the latest advancements. Our adoption of advanced CAD/CAM technology and high - precision injection molding machines ensures that we can meet strict dimensional tolerances and produce high - quality products. We also have a strong R & D team that is constantly exploring new molding techniques to better serve our customers.

Finally, we prioritize customer service. We are highly responsive to customer inquiries, providing quick answers and solutions. Our after - sales support is also comprehensive, including product inspection, maintenance advice, and handling of any quality - related issues. We believe that by focusing on these aspects, we can help our customers make the best choice for their injection molding needs.

FAQs

1. How can I be sure the injection molding company can handle my complex design?

To determine if an injection molding company can handle your complex design, first, check their technical capabilities. A company with advanced CAD/CAM technology can simulate the molding process for your design, identifying potential issues like poor material flow or insufficient wall thickness in advance. Secondly, review their portfolio of past projects. If they have successfully completed projects with similar complexity, such as parts with intricate internal structures or thin - walled designs, it's a strong indication they can manage yours. You can also ask for references from their previous clients who had complex design requirements and inquire about their experience.

2. What is the typical lead time for an injection molding project?

The lead time for an injection molding project can vary. The mold design phase usually takes 2 - 6 weeks, depending on the complexity of the mold. Once the mold is ready, the production cycle time for each part can range from a few seconds to a few minutes. For a small - scale production run of 1,000 - 5,000 parts, it may take 1 - 2 weeks. Larger orders, say 50,000 - 100,000 parts, could take 3 - 6 weeks. However, these times can be affected by factors like the availability of raw materials, the company's current order volume, and any unforeseen issues during production.

3. How do I know if the injection molding company uses high - quality materials?

You can verify the quality of materials used by the injection molding company in several ways. First, check if they have material certifications, such as ISO 1043 for plastics, which indicates that the materials meet certain international standards. Second, inquire about their material suppliers. Reputable companies usually source materials from well - known and reliable suppliers. Additionally, ask about their in - house material testing procedures. They should conduct tests like melt flow index testing, density testing, and tensile strength testing to ensure the materials' quality before using them in production.

Conclusion

Choosing the best injection molding service company is a multi - faceted decision that requires careful consideration of various factors. Experience and expertise are the foundation, ensuring that the company has the knowledge to handle different projects effectively. Quality assurance measures, from certifications to in - house quality control processes, guarantee that the final products meet high standards. Modern equipment and technology, such as advanced injection molding machines and CAD/CAM systems, not only improve the quality of the products but also enhance production efficiency. Cost - effectiveness, with a clear understanding of the pricing structure and potential hidden costs, helps in budget management. Finally, excellent customer service, both in terms of responsiveness and after - sales support, contributes to a smooth and satisfactory business relationship.

By thoroughly evaluating injection molding service companies based on these factors, businesses can find a reliable partner that will bring their product ideas to life with high quality, cost - efficiency, and on - time delivery. Whether it's a small - scale project for a startup or a large - volume production for a multinational corporation, making the right choice in injection molding service companies can have a significant impact on the success of the product and the overall business.