Introduction

In the ever - evolving landscape of modern manufacturing, precision prototype machining stands as a cornerstone of innovation. It serves as the bridge between a raw concept and a fully - fledged, market - ready product. As industries across the globe strive for enhanced efficiency, performance, and uniqueness, precision prototype machining has emerged as an indispensable tool.

Think about the aerospace industry, where the slightest deviation in a component can lead to catastrophic consequences. A single part of an aircraft engine, for Yigu Technology example, must be machined with extreme precision to ensure optimal fuel combustion, efficient power generation, and safe flight operations. In this context, precision prototype machining allows engineers to test and refine these critical components before mass production, saving both time and resources.

Or consider the medical device sector. New surgical instruments or implantable devices need to be not only functional but also biocompatible and ergonomic. Precision prototype machining enables the creation of prototypes that closely mimic the final product, allowing for thorough testing in a clinical - like environment. This ensures that when the actual product is launched, it meets the high - standards of patient safety and medical effectiveness.

The automotive industry is another prime example. With the push towards electric vehicles and autonomous driving, manufacturers are constantly developing new components and systems. Precision prototype machining helps in quickly iterating on designs for batteries, sensors, and other crucial parts. By creating accurate prototypes early in the development cycle, companies can identify and rectify design flaws, reducing the risk of costly recalls and improving overall product quality.

In essence, precision prototype machining is not just about making parts with tight tolerances; it's about enabling innovation, reducing risks, and driving the manufacturing industry forward. In the following sections, we will delve deeper into how this process works, its key techniques, and its far - reaching impact on various industries.

What is Precision Prototype Machining

Definition

Precision prototype machining refers to the highly accurate manufacturing process of creating prototype components. It serves as a crucial step in product development, allowing companies to transform initial design concepts into tangible models for testing, evaluation, and refinement. By using advanced techniques and state - of - the - art equipment, precision prototype machining can achieve extremely tight tolerances, often within the micrometer range. This ensures that the prototypes closely mimic the final product in terms of size, shape, and functionality, providing valuable insights for engineers and designers before moving forward with mass production.

Key Characteristics

- High Precision: The most prominent feature of precision prototype machining is its ability to achieve extremely high levels of accuracy. Tolerances can be maintained within ±0.001 mm or even tighter in some advanced cases. For Yigu Technology example, in the production of micro - electromechanical systems (MEMS), components need to be machined with such precision to ensure proper functionality. A comparison of general machining and precision prototype machining in terms of tolerance is shown in the following table:

| Machining Type | Typical Tolerance Range |

| General Machining | ±0.1 - ±1 mm |

| Precision Prototype Machining | ±0.001 - ±0.01 mm |

- Use of Advanced Equipment: Precision prototype machining relies on advanced machine tools such as computer - numerical - control (CNC) mills, lathes, and electrical discharge machining (EDM) equipment. CNC machines, for instance, can execute complex machining operations with high repeatability, following precise digital instructions. A high - end CNC milling machine can have positioning accuracy of up to ±0.0005 mm, enabling the creation of intricate geometries with ease.

- Advanced Machining Processes: It involves a variety of advanced processes. One such process is multi - axis machining, which allows for the creation of complex 3D shapes in a single setup. In 5 - axis machining, for Yigu Technology example, the workpiece can be rotated and tilted in multiple directions while being machined, reducing the need for multiple setups and improving the overall accuracy. Another process is micro - machining, which is specifically designed for creating miniature components. Micro - milling, for instance, can produce features with diameters as small as 0.05 mm, opening up new possibilities for the development of small - scale devices.

- Material Flexibility: Precision prototype machining can work with a wide range of materials, including metals (such as aluminum, titanium, and stainless steel), plastics (such as polycarbonate and ABS), and even some ceramics. Different materials have different machining characteristics, and precision prototype machining techniques are adaptable to ensure high - quality results regardless of the material used. For example, titanium is a difficult - to - machine material due to its high strength and low thermal conductivity, but with the right precision machining methods, it can be processed into high - quality prototypes for aerospace and medical applications. These key characteristics work in tandem to make precision prototype machining an essential tool in modern manufacturing, enabling the creation of high - quality prototypes that are vital for innovation and product development.

The Process of Precision Prototype Machining

Step - by - Step Explanation

- Design Phase:

- Conceptualization: The process begins with a detailed design concept. Engineers use computer - aided design (CAD) software to create 3D models of the prototype. These models are not only a visual representation but also contain all the necessary geometric and dimensional information. For Yigu Technology example, in the development of a new smartphone prototype, the CAD model will define the exact shape of the phone, the position of ports, buttons, and the internal components' layout.

- Design Review: Multiple stakeholders, including mechanical engineers, electrical engineers (if applicable), and product managers, review the design. This review ensures that the design meets the functional requirements, is manufacturable, and adheres to any relevant industry standards. Any potential design flaws are identified and rectified at this stage.

- Material Selection:

- Material Compatibility: The choice of material is crucial and depends on the prototype's intended application. For a prototype in the automotive industry that requires high strength and heat resistance, materials like aluminum alloys or high - strength steels might be selected. In contrast, for a medical device prototype where biocompatibility is essential, materials such as titanium or certain types of medical - grade plastics will be considered.

- Material Properties Analysis: Engineers analyze the mechanical, thermal, and chemical properties of the selected materials. They use data sheets provided by material suppliers and conduct in - house tests if necessary. For instance, when choosing a plastic for a consumer electronics prototype, they will look at its impact resistance, electrical insulation properties, and how it responds to different temperatures.

- Machining Operation:

- CNC Machining Setup: If CNC machining is used (which is very common in precision prototype machining), the machine is programmed according to the CAD model. The workpiece is securely clamped in the machine, and the cutting tools are selected based on the material and the required machining operations (such as milling, turning, or drilling). For example, a carbide - tipped end - mill might be used for milling a hardened steel workpiece.

- Multi - Axis Machining Execution: In multi - axis machining, the workpiece is moved and rotated in multiple directions simultaneously. In 5 - axis machining, the machine can control the movement of the workpiece along the X, Y, and Z axes, as well as two rotational axes (A and B or C). This allows for the creation of complex shapes in a single setup, reducing the need for multiple operations and potential errors.

- Micro - Machining for Miniature Components: When creating miniature components, micro - machining techniques are employed. Micro - milling, for example, uses extremely small cutting tools to remove material in tiny amounts. This is essential for producing features like micro - channels in microfluidic devices or small gears in MEMS.

- Quality Inspection:

- In - Process Inspection: During the machining process, regular inspections are carried out. This can involve using measuring tools such as calipers, micrometers, or coordinate measuring machines (CMMs) to check the dimensions of the workpiece at various stages. For Yigu Technology example, after a rough milling operation, the dimensions are measured to ensure that the material removal is on track and that the part is within the acceptable tolerance range.

- Final Inspection: Once the machining is complete, a comprehensive final inspection is conducted. The prototype is thoroughly checked for dimensional accuracy, surface finish, and any defects. High - resolution optical microscopes can be used to inspect the surface for any scratches or imperfections, while CMMs can provide highly accurate 3D measurements to verify that the final product matches the original design specifications.

Advanced Technologies Involved

- CNC Machining:

- High - Precision Control: CNC machines are controlled by computer programs, which allows for extremely precise movement. The positioning accuracy of modern CNC machines can be as high as ±0.0005 mm. This high - precision control enables the machining of complex geometries with tight tolerances. For example, in the production of aerospace components, CNC machining can create parts with intricate shapes that require very precise alignment of different features.

- Automation and Repeatability: CNC machining is highly automated, which means that once the program is set up, the machine can repeat the same operations with consistent results. This is crucial for producing multiple prototypes with identical specifications. In a research and development setting, where several iterations of a prototype might be needed, the repeatability of CNC machining ensures that each prototype has the same high - quality standards.

- Electrical Discharge Machining (EDM):

- Non - Traditional Material Removal: EDM is a non - traditional machining process that uses electrical discharges (sparks) to remove material from the workpiece. It is particularly useful for machining hard or brittle materials that are difficult to process with traditional cutting methods. For example, it can be used to machine tungsten carbide, which is a very hard material used in tooling applications.

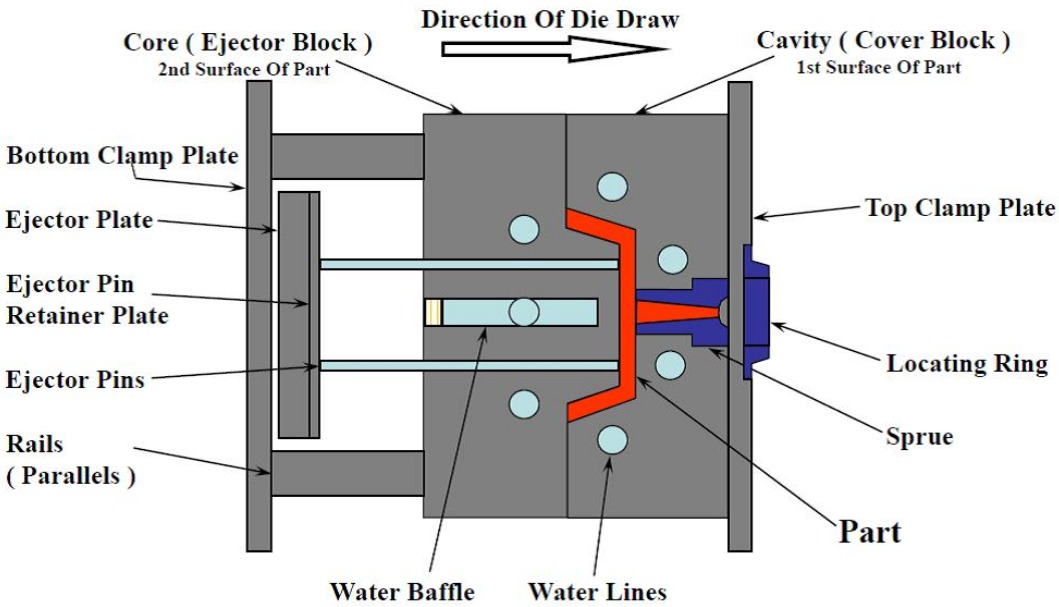

- High - Precision Molding and Die - Making: EDM is often used in the production of molds and dies. It can create extremely precise cavities and intricate details in the mold, which are then used to manufacture plastic or metal parts. In the plastic injection molding industry, EDM - produced molds can ensure that the final plastic products have high - quality surface finishes and accurate dimensions.

- Additive Manufacturing (3D Printing) in Precision Machining:

- Complex Geometry Creation: Additive manufacturing allows for the creation of complex geometries that are difficult or impossible to achieve with traditional machining methods. Lattice structures, for example, can be easily printed using 3D printers. In the development of lightweight components for the aerospace or automotive industries, these lattice structures can provide strength while reducing weight.

- Rapid Prototyping and Iteration: 3D printing enables rapid prototyping. Engineers can quickly print a prototype, test it, and make design modifications. This significantly reduces the time and cost associated with the prototype development cycle. For start - up companies or small - scale research projects, 3D printing can be a cost - effective way to create precision prototypes without the need for expensive tooling.

Comparison with Traditional Machining Methods (Table - based)

Create a Comparison Table

When considering the manufacturing process, it's essential to understand how precision prototype machining stacks up against traditional machining methods. The following Yigu Technology table clearly illustrates the differences in several key aspects:

| Comparison Items | Precision Prototype Machining | Traditional Machining |

| Precision Level | Can achieve extremely tight tolerances, often as precise as ±0.001mm. This high - precision capability is crucial for industries like aerospace and medical device manufacturing, where even the slightest deviation can have significant consequences. For example, in the production of components for satellite communication systems, the precision of ±0.001mm ensures optimal signal transmission and reception. | Has relatively larger tolerances, typically around ±0.1mm. This level of precision may be sufficient for some general - purpose applications, but it falls short in industries with strict requirements. In the manufacturing of simple household appliances, a tolerance of ±0.1mm might be acceptable for certain non - critical parts. |

| Production Time for Prototypes | Usually takes a relatively short time. Complex prototypes can be completed within a few days. This quick turnaround is due to the use of advanced CNC programming and automated machining processes. For a start - up company developing a new consumer electronics product, getting a prototype in a few days allows for rapid iteration and faster time - to - market. | Takes a longer time, potentially several weeks. Traditional machining often involves more manual operations, complex set - ups, and multiple steps for tool changes and adjustments. In the production of large - scale industrial equipment prototypes, the long production time can delay the entire product development cycle. |

| Material Utilization | Exhibits high material utilization. Advanced machining techniques, such as 5 - axis machining and additive manufacturing in precision machining, enable more efficient use of materials. In the production of lightweight components for the automotive industry, 3D printing (a form of additive manufacturing in precision machining) can create complex internal structures that reduce material waste while maintaining strength. | Has lower material utilization. Traditional machining methods like subtractive machining often result in a significant amount of waste material. When machining a metal block into a specific shape using traditional milling techniques, a large portion of the original material may be cut away and discarded. |

| Design Flexibility | Offers high design flexibility. Engineers can quickly modify the digital design in CAD software, and the CNC machines can then execute the new design immediately. In the development of custom - designed jewelry prototypes, designers can easily change the shape, size, and details of the design and have a new prototype made in a short time. | Has limited design flexibility. Once the machining process has started, making significant design changes can be difficult and costly. In traditional die - casting for automotive parts, changing the design of the die after production has begun requires expensive re - tooling and can cause significant production delays. |

As shown in the table, precision prototype machining has distinct advantages over traditional machining methods in terms of precision, production time, material utilization, and design flexibility. These advantages make it the preferred choice for many modern manufacturing applications, especially those that demand high - quality prototypes and rapid product development.

Conclusion

In Yigu Technology summary, precision prototype machining has emerged as a game - changer in the manufacturing landscape. Its high - precision capabilities, enabled by advanced equipment and techniques, have allowed for the creation of prototypes that are not only incredibly accurate but also highly functional.

The process of precision prototype machining, from the initial design phase to the final quality inspection, is a well - orchestrated sequence that ensures the highest standards are met. Advanced technologies such as CNC machining, EDM, and additive manufacturing have further enhanced its capabilities, making it possible to produce prototypes with complex geometries and in a shorter time frame.

When compared to traditional machining methods, precision prototype machining offers distinct advantages in terms of precision, production time, material utilization, and design flexibility. These advantages have made it an essential tool for industries that demand innovation and rapid product development, such as aerospace, automotive, medical, and consumer electronics.

Precision prototype machining is not just a manufacturing process; it is the driving force behind innovation in manufacturing. It enables companies to bring their ideas to life, test them thoroughly, and refine them into market - ready products. By reducing the risks associated with product development and shortening the time - to - market, precision prototype machining has become a key factor in the success of modern manufacturing enterprises. As technology continues to advance, we can expect precision prototype machining to play an even more significant role in shaping the future of manufacturing.

FAQ

1. What materials are most suitable for precision prototype machining?

Materials such as aluminum, titanium, stainless steel, polycarbonate, and ABS are commonly used. Aluminum is popular for its lightweight and good machinability, making it suitable for aerospace and automotive applications. Titanium is ideal for medical and high - strength applications due to its biocompatibility and high strength - to - weight ratio. Plastics like polycarbonate and ABS are great for consumer electronics prototypes as they offer good mechanical properties and are easy to machine.

2. How does precision prototype machining reduce the cost of product development?

Precision prototype machining allows for early detection and correction of design flaws. By creating accurate prototypes, companies can avoid costly design changes during mass production. Additionally, the high - precision nature of the process reduces the need for rework, saving both time and material costs. The relatively short production time for prototypes also means that companies can iterate on their designs more quickly, getting their products to market faster and reducing the overall cost of development.

3. Can precision prototype machining be used for small - batch production?

Yes, precision prototype machining can be used for small - batch production. The advanced equipment and techniques, especially CNC machining, offer high repeatability, which ensures consistent quality across small - batch production runs. This is beneficial for companies that need to produce a limited number of high - quality parts, such as for custom - made products, low - volume specialty items, or initial production runs for market testing.