Understanding Thermal Injection Molds

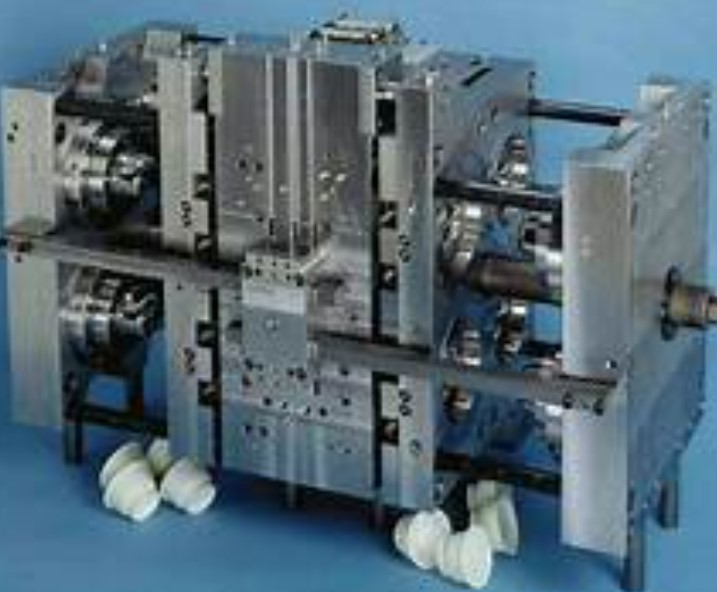

Thermal injection molds play a pivotal role in modern manufacturing processes. They are the key to producing high - precision plastic parts with complex shapes efficiently. By definition, thermal injection molds are tools used in the injection molding process, which involves injecting molten plastic material into a mold cavity. Once the plastic cools and solidifies, it takes on the shape of the cavity, and the final product is ejected.

Working Principle

The working principle of thermal injection molds is relatively straightforward yet highly precise. First, plastic pellets are fed into a heated barrel, where they are melted into a viscous liquid state. A screw - like mechanism then forces this molten plastic through a nozzle and into the mold cavity. The mold is designed with channels for coolant (usually water) to flow through, which rapidly cools the plastic inside the cavity, causing it to solidify. Once solidified, the two halves of the mold open, and the finished part is ejected, ready for further processing or use.

Application Areas

- Automotive Industry: In the automotive sector, thermal injection molds are used to create a wide range of components. For example, interior parts such as dashboards, door panels, and center consoles are often made using injection molding. These parts require high precision and durability. Exterior components like bumpers, grilles, and body panels are also commonly produced with the help of thermal injection molds. According to industry reports, over 70% of non - metallic parts in a modern car are made through injection molding processes.

- Electronics Industry: The electronics industry heavily relies on thermal injection molds for manufacturing various components. Small and intricate parts such as connectors, housings for electronic devices like smartphones, tablets, and laptops, and components for circuit boards are all produced using injection molding. The high precision offered by these molds ensures that the parts fit together perfectly, which is crucial for the proper functioning of electronic devices. For instance, the housings of smartphones need to be precisely molded to protect the internal components while also providing an aesthetically pleasing design.

- Medical Industry: In the medical field, thermal injection molds are used to produce a variety of disposable and non - disposable medical devices. Syringes, pipettes, test tubes, and components for medical equipment are all made through injection molding. The materials used in these molds must meet strict biocompatibility standards to ensure the safety of patients. For example, the molds used to make syringes need to be highly precise to ensure accurate dosing of medications.

Strategies to Build High - Quality Thermal Injection Molds on a Budget

1. Material Selection

The choice of materials for thermal injection molds significantly impacts both quality and cost. Steel - based materials are the most common. For example, P20 steel is a popular choice. It has a good balance of strength, machinability, and cost - effectiveness. P20 steel typically costs around \(5 - \)10 per pound, making it suitable for medium - production - volume molds. It can be easily machined into complex shapes, which is crucial for creating intricate mold cavities. However, for high - precision and long - lasting molds, S136 steel might be a better option. S136 offers excellent corrosion resistance and mirror - polishing properties, which are essential for producing high - quality plastic parts with smooth surfaces. But it comes at a higher cost, approximately \(15 - \)25 per pound.

Aluminum alloys are another alternative. They have a much lower density compared to steel, which means they are lighter and can lead to faster cycling times in the injection molding process due to their better thermal conductivity. Aluminum molds can be up to 3 - 5 times faster in cooling cycles compared to some steel molds. The cost of aluminum alloys for molds is generally in the range of \(3 - \)8 per pound. However, they are not as durable as steel, and their hardness is lower, so they may not be suitable for high - volume production runs or for molding abrasive plastic materials.

When selecting materials, consider the production volume. For low - volume production (less than 50,000 parts), aluminum alloys or lower - cost steels like P20 can be sufficient. For high - volume production (over 500,000 parts), investing in higher - quality steels such as S136 can save costs in the long run due to their longer lifespan and better performance.

2. Design Optimization

Optimizing the design of thermal injection molds is a key strategy for cost - effective production. Simplifying the mold structure can significantly reduce manufacturing costs. For example, avoiding unnecessary undercuts and complex geometric features that require additional machining operations or the use of side - action mechanisms. A simple two - plate mold design is often the most cost - effective for basic plastic parts. It has fewer components compared to more complex multi - plate molds, which means less machining, assembly, and maintenance.

Efficient layout of the runner system is also crucial. The runner is the channel through which the molten plastic flows from the injection nozzle to the mold cavity. A well - designed runner system minimizes the amount of wasted plastic. For instance, using a balanced runner system ensures that the plastic is evenly distributed to all cavities in a multi - cavity mold. This reduces the risk of short - shots (incomplete filling of the cavities) and over - packing (excessive plastic in the cavities), both of which can lead to defective parts and increased material waste. By reducing the cross - sectional area of the runner without sacrificing flow efficiency, the amount of plastic used in the runner can be decreased. A properly designed runner system can reduce material waste by up to 20 - 30%.

Another design principle is to standardize components as much as possible. Using standard - sized guide pins, ejector pins, and other mold components can lower costs. Standard components are readily available, often at a lower price, and they also simplify the replacement process in case of wear or damage.

3. Manufacturing Process Selection

There are several manufacturing processes available for producing thermal injection molds, each with its own cost - benefit profile. CNC machining is a widely used process. It offers high precision and can create complex shapes. However, it can be time - consuming and costly, especially for molds with intricate geometries. The cost of CNC machining can range from \(50 - \)200 per hour, depending on the complexity of the job and the type of equipment used. For simple molds with basic shapes, CNC machining can be a cost - effective option as it can produce the mold with high accuracy in a relatively short time.

EDM (Electrical Discharge Machining) is useful for creating detailed and precise features in the mold, such as fine textures or sharp corners. But it is a slow process and can be expensive. EDM costs are typically based on the machining time and the amount of material removed. For example, a small EDM job for creating a simple feature in a mold might cost a few hundred dollars, while a large - scale EDM project for a complex mold cavity could cost several thousand dollars.

3D printing is emerging as an alternative manufacturing process for injection molds. It can be faster and more cost - effective for producing small - batch or custom - designed molds. 3D printing allows for the creation of complex internal structures that are difficult to achieve with traditional machining methods. The cost of 3D printing molds depends on the size of the mold, the material used, and the complexity of the design. For small, simple molds, 3D printing can be a very cost - effective option, with costs starting from a few hundred dollars. However, for large - scale production molds, the current limitations in 3D printing technology, such as slower build times and potential issues with material properties, may make it less suitable.

When choosing a manufacturing process, consider the complexity of the mold, the production volume, and the required precision. For high - precision, high - volume production molds, a combination of CNC machining and EDM might be the best choice. For low - volume or custom - designed molds, 3D printing could offer significant cost savings.

4. Collaboration with Suppliers

Building a strong relationship with suppliers is essential for reducing the cost of thermal injection molds. Negotiating better prices is one of the most straightforward ways. By placing larger orders, you can often secure volume discounts. For example, if you regularly purchase steel for mold making, negotiating a lower price per pound based on a larger order quantity can result in substantial savings. A 10 - 20% price reduction is not uncommon when ordering in bulk.

Finding reliable and cost - effective suppliers is also crucial. Don't just focus on the lowest - cost supplier; consider the quality of their products and services. A reliable supplier will provide consistent quality materials, on - time delivery, and good after - sales support. You can research different suppliers, read reviews from other manufacturers, and even visit their facilities if possible. Some suppliers may offer value - added services such as pre - machining of materials, which can save you time and money in the mold - making process.

Another approach is to establish long - term partnerships with suppliers. Long - term relationships can lead to more favorable pricing, priority access to new materials or technologies, and better communication. Suppliers are more likely to invest in meeting your specific needs if they know they have a long - term business relationship with you. For instance, they may be willing to work with you on cost - reduction initiatives, such as finding alternative materials that meet your quality requirements at a lower cost.

Case Studies

Case 1: Automotive Component Manufacturer

A mid - sized automotive component manufacturer needed to produce a new line of plastic interior door handles. The budget for the thermal injection molds was tight, with a limit of $50,000. The company followed several strategies to build high - quality molds within the budget.

Material Selection: They chose P20 steel for the mold. Considering the production volume of around 300,000 units over the next two years, P20 steel offered a good balance of cost and performance. The cost of P20 steel for this project was approximately $20,000, which was 40% of the total budget.

Design Optimization: The design team simplified the mold structure. By removing some unnecessary decorative grooves on the door handle design, they eliminated the need for complex side - action mechanisms. This reduced the machining time and cost. The runner system was redesigned to be a balanced, circular - shaped runner. This change reduced the amount of wasted plastic by about 25%, saving an estimated $5,000 in material costs over the production run.

Manufacturing Process: CNC machining was selected as the primary manufacturing process. The mold had relatively simple geometries, and CNC machining could achieve the required precision at a reasonable cost. The total machining cost was around $25,000.

Result: The molds were completed within the budget of $50,000. The high - quality molds produced door handles with consistent quality, meeting all the automotive industry's standards. The defect rate was less than 1%, and the production efficiency was high, with a cycle time of 30 seconds per part, which met the production targets.

Case 2: Electronics Device Manufacturer

An electronics company was developing a new smartphone case. The budget for the thermal injection molds was set at $80,000.

Material Selection: For this high - precision application, S136 steel was chosen despite its higher cost. Since the smartphone cases required a smooth, mirror - like surface finish and had a high - volume production plan of over 1 million units, S136 steel's properties were essential. The cost of S136 steel for the molds was $35,000, taking up 43.75% of the budget.

Design Optimization: The design team standardized as many components as possible. They used standard - sized guide pins and ejector pins, which reduced the cost of component procurement and machining. The mold design also incorporated a modular approach, allowing for easy replacement of worn - out parts. This modular design increased the mold's lifespan and reduced long - term maintenance costs.

Manufacturing Process: A combination of CNC machining and EDM was used. CNC machining was used for the general shaping of the mold, while EDM was employed to create the fine details and texturing on the mold surface. The CNC machining cost was \(30,000, and the EDM cost was \)10,000.

Result: The molds were successfully produced within the budget. The high - quality S136 steel molds, combined with the optimized design and manufacturing processes, produced smartphone cases with a defect rate of less than 0.5%. The surface finish of the cases was excellent, meeting the high - end aesthetic requirements of the electronics market. The production cycle time was 25 seconds per part, enabling the company to meet the high - volume production demands.

From these case studies, we can see that by carefully considering material selection, design optimization, manufacturing process selection, and collaboration with suppliers, it is possible to build high - quality thermal injection molds on a budget. Each strategy plays a crucial role in achieving the right balance between cost and quality, and the specific combination of strategies depends on the specific requirements of the project, such as production volume, precision, and surface finish requirements.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the challenges of building high - quality thermal injection molds on a budget. With years of experience in the field, we have developed a set of strategies that ensure both quality and cost - effectiveness.

In terms of material selection, we have an extensive range of materials at our disposal. We work closely with reliable material suppliers to source high - quality yet affordable materials. Whether it's finding the right grade of steel or a suitable aluminum alloy, we can provide customized material solutions based on our clients' production volume, part complexity, and budget constraints.

Our design team is proficient in optimizing mold designs. We use advanced CAD/CAM software to create highly efficient and cost - effective mold designs. By simplifying the mold structure, standardizing components, and optimizing the runner system, we can significantly reduce manufacturing costs without sacrificing quality.

In manufacturing, Yigu Technology adopts a combination of advanced manufacturing technologies. We have state - of - the - art CNC machining centers, EDM equipment, and are also exploring the potential of 3D printing for certain mold applications. This allows us to choose the most suitable manufacturing process for each project, balancing precision, speed, and cost.

Moreover, we implement strict quality control measures at every stage of the mold - making process. From material inspection to the final mold assembly, our quality control team ensures that the molds meet the highest industry standards. This not only guarantees the quality of the molds but also reduces the risk of costly rework and production delays.

FAQ

1. What are the most cost - effective materials for thermal injection molds?

Steel - based materials like P20 steel, costing around \(5 - \)10 per pound, are cost - effective for medium - production - volume molds. It has good machinability. Aluminum alloys, priced at \(3 - \)8 per pound, are lighter and have better thermal conductivity, leading to faster cycling times, but are less durable. For low - volume production, aluminum alloys or P20 steel can be suitable. For high - volume production, higher - quality steels such as S136 (costing \(15 - \)25 per pound) with better durability may save costs in the long run.

2. How can I optimize the design of thermal injection molds to reduce costs?

Simplify the mold structure by avoiding unnecessary undercuts and complex features. A two - plate mold design is often the most cost - effective for basic parts. Optimize the runner system; use a balanced runner to evenly distribute plastic and reduce waste. For example, a well - designed runner can cut material waste by 20 - 30%. Standardize components like guide pins and ejector pins to lower costs as they are more readily available and easier to replace.

3. How important is the choice of manufacturing process for cost control?

The choice of manufacturing process is crucial. CNC machining offers high precision but can be time - consuming and costly (\(50 - \)200 per hour). It's suitable for simple molds with basic shapes. EDM is good for creating detailed features but is slow and expensive. 3D printing can be faster and more cost - effective for small - batch or custom - designed molds. For high - precision, high - volume production molds, a combination of CNC machining and EDM might be best. For low - volume or custom - designed molds, 3D printing could offer significant cost savings.