Introduction

In the manufacturing industry, choosing the right mould factory for cooperation is of utmost importance. The quality of moulds directly impacts the quality of the final products, production efficiency, and overall costs. A sub - optimal choice can lead to defective products, production delays, and increased expenses. This article will explore from multiple aspects such as product quality, production capacity, cost - effectiveness, and after - sales service to help you figure out which kind of mould factory is better for cooperation. By the end, you'll be equipped with the knowledge to make an informed decision and build a successful partnership in the mould - making field.

Production Capacity

Equipment and Technology

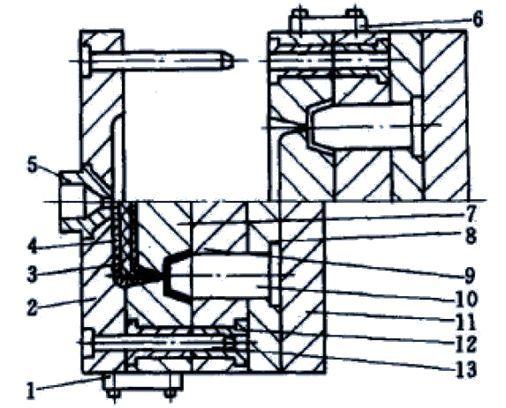

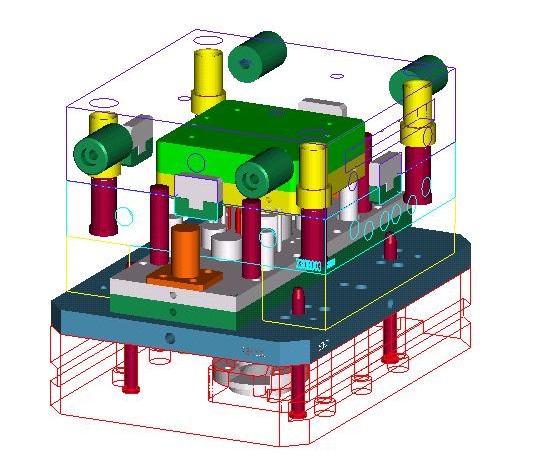

Advanced equipment is the cornerstone of high - production - capacity mould factories. High - precision machining centers can achieve extremely accurate milling, drilling, and boring operations. For example, a five - axis machining center can process complex three - dimensional mould shapes with high precision. It allows the workpiece to be machined from multiple angles without re - clamping, reducing errors and improving production efficiency. The positioning accuracy of high - end machining centers can reach up to ±0.001mm, which is crucial for manufacturing moulds with tight tolerances.

CNC electrical discharge machining (EDM) machines are also essential. They use electrical discharges to erode the workpiece and create intricate shapes that are difficult to machine by traditional methods. In a precision mould production for a high - end electronic product, an EDM machine can create micro - structures with a minimum feature size of 0.01mm. Factories equipped with such advanced EDM machines can handle complex mould designs more efficiently, which significantly boosts production capacity and product quality.

Production Scale

The production scale of a mould factory directly affects its order - handling ability and production cycle. The following table shows the differences between large - scale and small - scale mould factories:

| Factory Scale | Monthly Production Capacity (Sets) | Average Order - Handling Capacity per Month | Average Production Cycle for a Medium - Sized Mould Order |

| Large - scale | 500 - 1000 | 30 - 50 | 2 - 3 months |

| Small - scale | 50 - 150 | 5 - 10 | 4 - 6 months |

Large - scale mould factories usually have more production lines, a larger number of workers, and better - organized production management systems. They can handle large - volume orders from major automotive or electronics manufacturers. In contrast, small - scale mould factories are more suitable for small - batch, customized orders due to their limited resources and production capacity.

Product Quality

Quality Control System

A sound quality control system is the bedrock of a high - quality mould factory. It typically encompasses raw material inspection, in - production process monitoring, and finished - product testing.

Take a mould factory that has obtained ISO 9001 certification as an example. Before production starts, they conduct strict raw material inspections. They use spectrometers to analyze the chemical composition of metal materials to ensure they meet the required standards. For example, if the mould is made of a specific alloy steel, the spectrometer can accurately measure the content of elements like carbon, chromium, and nickel, guaranteeing that the raw materials have the correct properties for the intended mould application.

During the production process, real - time monitoring is carried out. Sensors are installed on machining equipment to monitor parameters such as temperature, vibration, and cutting force. Abnormalities in these parameters may indicate tool wear, incorrect machining operations, or other issues that could affect the quality of the mould. For instance, if the temperature of a milling machine spindle rises abnormally, it might lead to thermal expansion of the cutting tools, resulting in dimensional inaccuracies in the mould parts.

Once the mould is completed, comprehensive finished - product testing is performed. Coordinate measuring machines (CMMs) are used to measure the dimensions of the mould with high precision. A CMM can measure complex three - dimensional shapes with an accuracy of up to ±0.001mm, ensuring that all the features of the mould meet the design requirements.

Material Selection

The choice of raw materials has a profound impact on mould quality. Different materials can lead to significant differences in mould durability and accuracy retention.

For example, in the production of injection moulds, using high - quality P20 steel compared to lower - grade steels can make a big difference. P20 steel has good machinability, hardness, and toughness. Moulds made of P20 steel can maintain their dimensional accuracy during long - term production runs. They can produce hundreds of thousands of injection - molded products with consistent quality. In contrast, lower - grade steels may experience more rapid wear and deformation during the injection - molding process. This can result in the production of defective products, as the mould cavity may gradually lose its original shape, leading to issues such as inconsistent wall thickness and surface defects in the molded parts.

Another example is in the manufacturing of die - casting moulds. Hot - work die steels like H13 are preferred due to their excellent heat resistance, high temperature strength, and thermal fatigue resistance. Die - casting moulds made of H13 steel can withstand the high - temperature and high - pressure environment during die - casting operations for a long time. They can produce high - quality die - cast parts with complex shapes. If an inappropriate material is used, the mould may crack or deform quickly under the harsh die - casting conditions, reducing the production efficiency and increasing the cost of mould replacement.

Professional Team

Technical Expertise

A professional team is the soul of a mould factory. In a high - end mould factory, the mould design team plays a crucial role. For example, a team with over 10 years of experience in mould design can significantly shorten the design cycle. On average, they can complete a complex mould design 30% faster than a less - experienced team. These experienced designers are proficient in using advanced design software like CAD (Computer - Aided Design) and CAE (Computer - Aided Engineering). CAD allows them to create highly detailed 2D and 3D models of the mould, accurately visualizing every component. CAE, on the other hand, enables them to simulate the mould - making process, analyze potential problems such as material flow and stress distribution in the design phase, and make timely adjustments.

Process engineers are also indispensable. They are responsible for translating the design into actual production processes. They have in - depth knowledge of various manufacturing processes, such as injection moulding, die - casting, and stamping. In an injection - moulding process, a skilled process engineer can optimize parameters like injection pressure, temperature, and cooling time. By doing so, they can improve the quality of the moulded products. For instance, they can reduce the occurrence of defects like warping and shrinkage by up to 50%, ensuring that the moulds produced can meet the high - quality requirements of customers.

Staff Training and Development

Continuous staff training and development are essential for maintaining the high - level performance of a mould factory. Regular training sessions should be held, perhaps quarterly or semi - annually. The training content can cover a wide range of aspects, including new mould - making technologies, updated software applications, and advanced quality control methods.

For example, with the continuous development of mould - making technology, new materials and processing techniques are emerging. Training on these new materials can help employees understand their properties and processing requirements. If a factory starts using a new type of high - strength, heat - resistant plastic for mould production, employees need to be trained on how to handle this material during the injection - moulding process. This includes understanding the appropriate melting temperature, injection speed, and cooling rate for this new plastic. Such training can improve employees' professional skills, enabling them to adapt to new production requirements and ultimately contribute to the factory's ability to produce high - quality moulds more efficiently.

Cost - effectiveness

Pricing Structure

The pricing of a mould factory is a complex structure that consists of several key components. Material cost is a significant part. For example, high - quality steel materials used in mould - making can vary greatly in price. A mould factory that uses premium - grade alloy steel might have a material cost that is 30% - 50% higher than one using common - grade steel for the same type of mould.

加工成本涵盖了从模具设计到最终生产的一系列流程费用。高精度的加工工艺,如前面提到的五轴加工和电火花加工,会显著增加加工成本。一个需要大量五轴加工工序的模具,其加工成本可能比仅使用传统三轴加工的模具高出 50% - 100%。

Processing cost encompasses a series of process fees from mould design to final production. High - precision processing techniques, such as the five - axis machining and EDM mentioned earlier, can significantly increase processing costs. A mould that requires a large number of five - axis machining operations may have a processing cost 50% - 100% higher than one that only uses traditional three - axis machining.

利润部分则与模具厂的运营策略和市场定位有关。一些高端模具厂凭借其卓越的品质和服务,利润空间可能在 20% - 30%;而一些以价格竞争为主的模具厂,利润可能控制在 10% - 15%。以下图表展示了不同模具厂价格构成的差异:

The profit part is related to the mould factory's operation strategy and market positioning. Some high - end mould factories, with their excellent quality and service, may have a profit margin of 20% - 30%; while some mould factories that mainly compete on price may control their profit at 10% - 15%. The following chart shows the differences in the price composition of different mould factories:

| Factory Type | Material Cost Percentage | Processing Cost Percentage | Profit Percentage |

| High - end | 40% - 50% | 30% - 40% | 20% - 30% |

| Mid - range | 50% - 60% | 25% - 35% | 15% - 20% |

| Low - cost - oriented | 60% - 70% | 20% - 30% | 10% - 15% |

Long - term Cost Considerations

Choosing a mould factory with low initial prices but poor quality may lead to significant long - term cost increases. For instance, if a mould has a short lifespan due to low - quality materials and sub - standard manufacturing processes, it will need to be replaced frequently.

Suppose the initial purchase cost of a set of moulds is \(10,000, and the expected service life is 10,000 production cycles. However, due to low - quality materials and sub - standard manufacturing processes, the actual service life is only 5,000 production cycles. If the value of each product in a production cycle is \)1, then for 10,000 production cycles, the original mould only needs one set, with a cost of \(10,000; while the low - quality mould needs two sets, with a cost of \)20,000, doubling the cost. In addition, frequent mould replacements will also lead to production interruptions, resulting in production delay costs. Statistics show that each production interruption may cause an average loss of \(5,000 - \)10,000 to the enterprise, including equipment idle costs, labor costs, and possible order delay fines.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology believes that when choosing a mould factory for cooperation, several key factors should be taken into account. Firstly, production capacity is crucial. A mould factory with advanced equipment and a large - scale production line can ensure timely delivery of orders, especially for large - volume projects. Secondly, product quality cannot be compromised. Stringent quality control systems and proper material selection are essential to produce high - quality moulds that meet our specific requirements.

In addition, a professional team with rich technical expertise and continuous training can better handle complex mould - making tasks and provide innovative solutions. Regarding cost - effectiveness, we not only consider the initial price but also the long - term cost, as low - quality moulds may lead to higher overall expenses. Finally, we value the establishment of long - term and stable cooperative relationships based on mutual trust and integrity. A reliable mould factory can grow with us and jointly meet the challenges of the market.