What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary technology that has been transforming various industries in recent years. At its core, 3D printing creates three-dimensional objects by layering materials based on a digital model file.

The process begins with a 3D model, which can be created using computer-aided design (CAD) software, 3D scanning, or even downloaded from online repositories. This digital model serves as the blueprint for the final physical object. Once the model is ready, a 3D printer reads the digital file and deposits materials layer by layer to build the object, much like how a traditional printer deposits ink on paper, but in a three-dimensional space.

Common materials used in 3D printing include plastics like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene), metals such as aluminum and titanium, ceramics, and even some specialized materials like edible filaments for food printing or biocompatible materials for medical applications. For example, PLA is a popular choice for hobbyists and beginners in 3D printing due to its relatively low cost, ease of use, and eco-friendly nature. It melts at a relatively low temperature, making it suitable for desktop 3D printers.

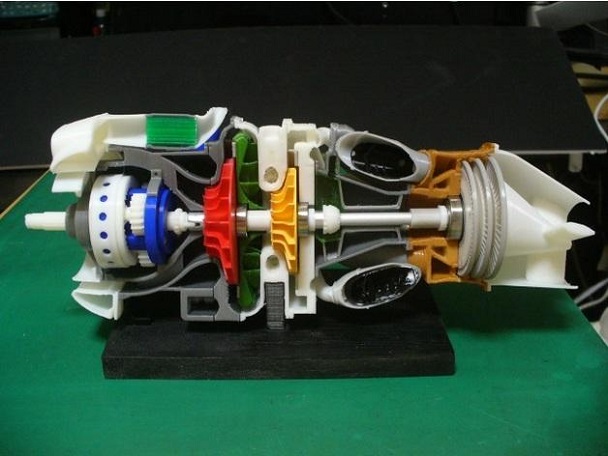

The versatility of 3D printing allows for the creation of objects with complex geometries that would be extremely difficult or even impossible to produce using traditional manufacturing methods. Traditional manufacturing often involves processes like subtractive manufacturing (e.g., cutting, milling) or formative manufacturing (e.g., molding), which have limitations in terms of the shapes they can create. In contrast, 3D printing can create intricate internal structures, lattice patterns, and unique shapes without the need for complex tooling or multiple manufacturing steps.

3D Printing in Consumer Products: A Growing Trend

Popular 3D Printed Consumer Products

3D printing has made its way into the consumer market in various forms, and some of the most popular 3D printed consumer products include:

- Jewelry: 3D printing allows for the creation of highly intricate and personalized jewelry designs. Designers can craft unique pieces with complex patterns and shapes that would be challenging to achieve through traditional manufacturing methods. For example, a 3D printed ring can feature a detailed lattice structure or a custom - shaped gem setting, appealing to consumers who want one - of - a - kind accessories.

- Home Decor and Furniture: From decorative vases with organic and fluid forms to customized furniture like stools or side tables, 3D printing offers a new level of creativity in home decor. A 3D printed lamp, for instance, can have a 3D - modeled, ergonomic handle that not only looks stylish but also provides a comfortable grip. These products often attract consumers looking to add a touch of uniqueness to their living spaces.

- Customized Gifts: Personalized gifts such as photo - engraved keychains, 3D - printed figurines modeled after a loved one, or custom - designed phone cases are in high demand. They add a personal touch that mass - produced gifts can't match. For example, a 3D printed keychain with a child's hand - drawn design on it makes for a special and memorable gift.

Market Statistics

The 3D printing consumer products market has been experiencing remarkable growth. According to a market research report, the global 3D printing consumer products market was valued at approximately \(X billion in 20XX and is projected to reach \)Y billion by 20XX, with a compound annual growth rate (CAGR) of around XX% during the forecast period. In the past five years alone, the market has seen a growth rate of over XX%. This growth is driven by factors such as the increasing availability of affordable 3D printers, the rise in consumer interest in personalized products, and the continuous development of 3D printing materials and technologies. For instance, the growth of the DIY 3D printing community has significantly contributed to the expansion of the consumer - facing 3D printing market, with more individuals purchasing 3D printers for personal use at home.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology sees great potential in 3D printing for consumer products. 3D printing has opened up new opportunities for our non - standard product customization services. It allows us to meet the unique and special requirements of our customers with precision. For example, when a customer needs a uniquely designed plastic component for a consumer electronic device, 3D printing enables us to quickly produce it without the need for complex and costly traditional manufacturing molds.

In small - batch custom production, 3D printing offers significant cost - effectiveness and efficiency advantages. We can start production immediately once the digital model is finalized, eliminating the long lead - time for mold - making in traditional manufacturing. However, we also acknowledge the challenges. The available materials for 3D printing are still somewhat limited, especially when it comes to high - performance materials required for certain consumer products. Additionally, the printing speed can be a bottleneck for large - scale production.

Despite these challenges, Yigu Technology will continue to closely monitor the development of 3D printing technology and actively explore its applications in non - standard plastic and metal product customization to better serve our customers in the consumer products market.

FAQs

What types of materials can be used for 3D printing consumer products?

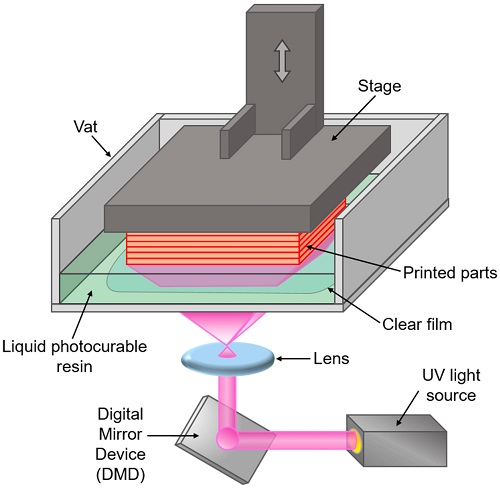

Common materials for 3D printing consumer products include thermoplastics like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene). PLA is popular for its eco - friendliness, low melting point, and ease of use, making it suitable for home 3D printers and items such as small figurines, phone cases, and some jewelry components. ABS is more durable and heat - resistant, often used for parts that need to withstand more stress, like small mechanical parts in consumer electronics. Photopolymer resins are used in stereolithography (SLA) 3D printing. They can achieve high - resolution prints, making them ideal for detailed jewelry, dental models, and art pieces. Metal powders such as aluminum, titanium, and stainless steel are used in metal 3D printing processes. Metal 3D - printed products are often found in high - end consumer goods like luxury watches and some high - performance sports equipment due to their strength and durability.

How much does it cost to start 3D printing consumer products at home?

The cost of starting 3D printing consumer products at home can vary. A basic entry - level desktop 3D printer can cost anywhere from \(200 to \)500. Mid - range printers with better features, such as higher printing precision and larger build volumes, may cost between \(500 and \)2000. High - end professional - grade desktop printers can exceed \(2000. The cost of materials also adds up. For example, a spool of PLA filament, which is a common 3D printing material, usually costs around \)20 to \(50 depending on the brand and quality. Some specialty materials can be much more expensive. Additionally, you may need to invest in 3D modeling software. There are free options like Tinkercad, but more advanced professional software can cost from \)100 to several hundred dollars per year. So, in total, starting 3D printing at home can cost around \(300 to \)3000 initially, depending on the printer and materials you choose.

Are 3D printed consumer products as durable as traditionally manufactured ones?

The durability of 3D printed consumer products compared to traditionally manufactured ones depends on several factors. When it comes to plastics, 3D printed parts made from materials like ABS can be quite durable for many applications. However, the layer - by - layer nature of 3D printing can sometimes create weak points along the layers, especially if the printing parameters are not optimized. In traditional injection - molded plastic products, the material is more uniformly distributed, which can result in greater strength in some cases. For metal products, 3D printed metals can have comparable or even superior strength in certain geometries. For example, in aerospace applications where 3D printed metal parts are used, they are designed to meet high - strength requirements. But for mass - produced simple metal consumer items like spoons, traditional forging or casting methods usually produce more consistent and durable products at a lower cost. In general, for simple and high - volume consumer products, traditional manufacturing often offers better durability, while 3D printing can be more suitable for complex, customized, or low - volume items where unique design features are prioritized over pure durability in some cases.