Introduction

Definition and Concept of 3D Printed RC Jets

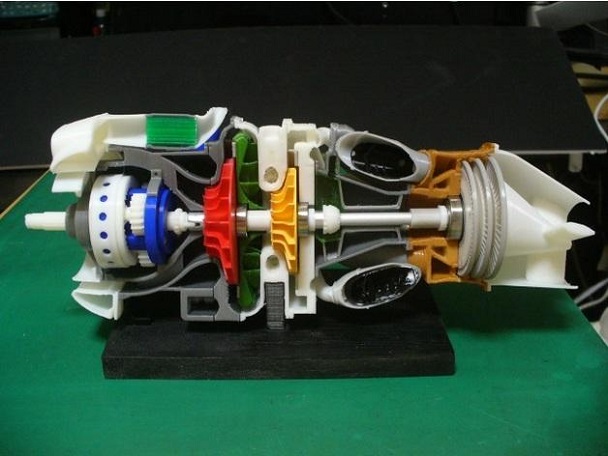

3D printed RC jets are radio - controlled model jets that are created using 3D printing technology. 3D printing, also known as additive manufacturing, involves building an object layer by layer from a digital 3D model. In the case of RC jets, this technology allows hobbyists and enthusiasts to design and produce highly detailed and customized jet models.

Traditionally, RC jets were made through methods like injection molding, which required expensive molds and had limitations in design complexity. With 3D printing, the process is much more flexible. Designers can create intricate shapes, such as complex air intakes, unique wing profiles, and detailed cockpit interiors, that would be extremely difficult or costly to produce with traditional manufacturing methods. For example, a 3D printed RC jet can have a more aerodynamically efficient fuselage shape, with smooth curves and precise angles, which can enhance its flight performance.

Popularity and Growing Interest in 3D Printed RC Jets

The popularity of 3D printed RC jets has been on the rise in recent years. According to a market research report, the global 3D printing market for hobby and DIY applications, which includes RC models, has been growing at an annual rate of approximately 15% in the past five years. This growth can be attributed to several factors.

Firstly, the decreasing cost of 3D printers has made it more accessible for hobbyists. A few years ago, a decent 3D printer could cost thousands of dollars, but now, entry - level models are available for as low as a few hundred dollars. This price drop has enabled more people to try their hand at 3D printing and create their own RC jet models. Secondly, the availability of online design platforms and communities has provided a wealth of resources. Enthusiasts can share their 3D models of RC jets on platforms like Thingiverse and Printables. There are now thousands of RC jet - related designs available for free or for a small fee, allowing users to easily find and customize a model that suits their needs.

Moreover, the ability to customize 3D printed RC jets is a major draw. Hobbyists can adjust the size, shape, and features of the jet to their liking, whether it's adding custom decals, modifying the wingspan for different flight characteristics, or creating a unique paint job. This level of personalization has significantly contributed to the growing interest in 3D printed RC jets among the hobbyist community.

Comparison with Traditional RC Jets

Performance Comparison

When it comes to performance, 3D printed RC jets have some notable differences compared to traditional ones. In terms of flight speed, traditional RC jets typically have a top speed in the range of 80 - 120 mph (miles per hour) depending on their size, engine power, and design. However, some well - designed 3D printed RC jets, especially those with optimized aerodynamic shapes, can reach speeds of up to 150 mph. This is because 3D printing allows for the creation of more streamlined and efficient airframes.

For flight stability, traditional RC jets often rely on standard wing and fuselage designs that have been tried and tested over the years. They usually offer a stable flight experience but may have limitations in terms of adaptability. 3D printed RC jets, on the other hand, can be designed with features like variable - geometry wings or custom - shaped stabilizers. For example, a 3D printed jet might have a wing design that can adjust its camber during flight, which can improve stability in different wind conditions. In a side - by - side comparison, a traditional RC jet might experience more turbulence and less stable flight in winds of 15 - 20 mph, while a 3D printed jet with the right design could maintain a more stable flight path.

| Comparison Items | Traditional RC Jets | 3D Printed RC Jets |

| Top Speed | 80 - 120 mph | Up to 150 mph |

| Stability in 15 - 20 mph Wind | Less stable, more turbulence | More stable, better flight path maintenance |

Cost Comparison

The cost aspect is also an important factor to consider. The initial purchase price of a ready - to - fly traditional RC jet can range from \(300 to \)1000, depending on its quality, brand, and features. For example, a mid - range traditional RC jet with a good - quality engine and basic electronics might cost around \(500. In contrast, the cost of a 3D printed RC jet mainly depends on the cost of the 3D printer, materials, and the design. If you already own a 3D printer, the cost of materials for a 3D printed RC jet could be as low as \)50 - $150 for the filament and other small components.

When it comes to maintenance costs, traditional RC jets often require regular servicing of their engines, which can cost \(50 - \)200 per service depending on the complexity of the engine. Additionally, replacing parts like propellers, which can get damaged during flights, can cost another \(10 - \)50 each time. 3D printed RC jets, on the other hand, have fewer moving parts in some cases, reducing the need for frequent engine servicing. If a part of a 3D printed jet gets damaged, it can often be printed again at a relatively low cost, usually just the cost of the filament, which might be a few dollars for a small part.

Manufacturing Process Comparison

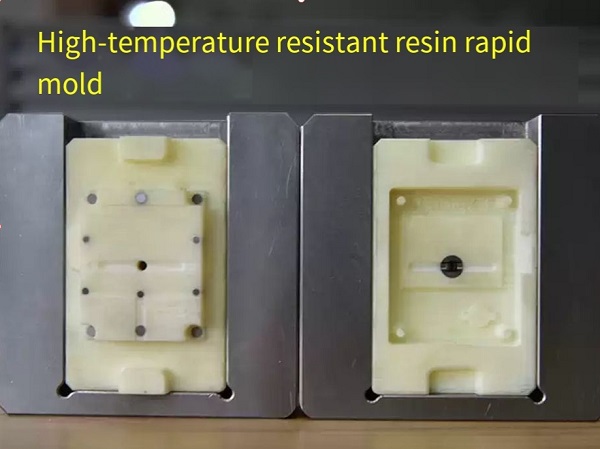

The manufacturing processes of 3D printed and traditional RC jets are quite different. Traditional RC jets are commonly made through injection molding. This process involves creating a mold, usually made of metal, which can be extremely expensive, costing thousands of dollars for a complex mold. Once the mold is made, molten plastic or other materials are injected into it under high pressure to form the various parts of the jet. This process is suitable for mass production but has high upfront costs and limited design flexibility.

In contrast, 3D printing is an additive manufacturing process. It starts with a 3D digital model created using computer - aided design (CAD) software. The 3D printer then builds the jet layer by layer, adding material precisely where it's needed. This allows for highly customized designs. For example, if you want to add a unique air intake shape or a complex internal structure for better weight distribution, it's relatively easy to do with 3D printing. The only real limitation is the build volume of the 3D printer. Also, 3D printing doesn't require expensive molds, making it a more cost - effective option for small - scale production or one - off custom builds.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology sees great potential in 3D printed RC jets. In terms of materials, we believe that the use of high - performance plastics and lightweight metals in 3D printing can significantly enhance the performance of RC jets. For example, materials like carbon - fiber - reinforced plastics offer high strength - to - weight ratios, which can make the jet more lightweight while maintaining its structural integrity during high - speed flights.

Our custom services can also play a crucial role. We can provide customized 3D printed parts according to the specific requirements of RC jet enthusiasts. Whether it's a unique wing design for better aerodynamics or a specialized cockpit structure for added functionality, our precision manufacturing capabilities ensure that the parts are produced with high accuracy. This not only meets the individual needs of hobbyists but also promotes innovation in the 3D printed RC jet community.

FAQ

Q1: What materials are commonly used for 3D printed RC jets?

Common materials for 3D printed RC jets include PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene). PLA is easy to print, biodegradable, and has good dimensional stability. It's suitable for beginners due to its relatively low printing temperature. ABS, on the other hand, is more durable and heat - resistant. It can withstand higher stress during flights, making it a great choice for high - performance RC jets, but it requires a heated print bed and proper ventilation during printing.

Q2: Can I modify the design of a 3D printed RC jet easily?

Yes, you can. Since 3D printed RC jets start from a digital 3D model, it's relatively easy to modify the design. Using CAD software, you can adjust the shape, size, or add/remove features. For example, you can change the wingspan to alter the flight characteristics, or add custom - shaped fins for better stability. Once the changes are made to the digital model, you can simply re - print the parts.

Q3: How long does it usually take to print a 3D printed RC jet?

The printing time depends on the size of the jet, the complexity of the design, and the 3D printer's speed. Generally, for a small - to - medium - sized 3D printed RC jet with a relatively simple design, it can take anywhere from 10 to 30 hours. Larger and more complex models might require 50 hours or even longer. For instance, a basic 3D printed RC jet with a wingspan of about 60 cm could be printed in around 15 - 20 hours on a mid - range 3D printer.