Introduction to 3D Printing in Medicine

The integration of 3D printing (or additive manufacturing) into the medical field has brought transformative changes, enabling the production of complex structures and devices tailored specifically to patients' needs. From creating custom prosthetics and implants to improving surgical planning, drug delivery systems, and even developing biological tissues, 3D printing is rapidly becoming a game-changer in healthcare. This revolutionary technology offers personalized solutions, enhances patient outcomes, reduces costs, and accelerates medical research and innovation. In this article, we explore the various ways in which 3D printing is revolutionizing medical applications, alongside its benefits, challenges, and future prospects.

Overview of 3D Printing Technology

Historical Context and Evolution

3D printing began as a method of rapid prototyping in the 1980s, primarily for industrial design and manufacturing. Initially, its applications were limited to creating simple prototypes for product testing. However, as the technology advanced, researchers began exploring its potential for more intricate applications, including medicine. By the early 2000s, 3D printing technology started to gain traction in healthcare, leading to a broad range of innovative medical applications. Today, it plays a vital role in the personalized treatment of patients and the development of customized healthcare solutions.

Mechanism and Materials

3D printing works by creating three-dimensional objects from digital files through the additive manufacturing process, where materials are deposited layer by layer. Common 3D printing methods used in medicine include:

- Fused Deposition Modeling (FDM): Used for creating physical objects from thermoplastic materials, often employed in prosthetics and implants.

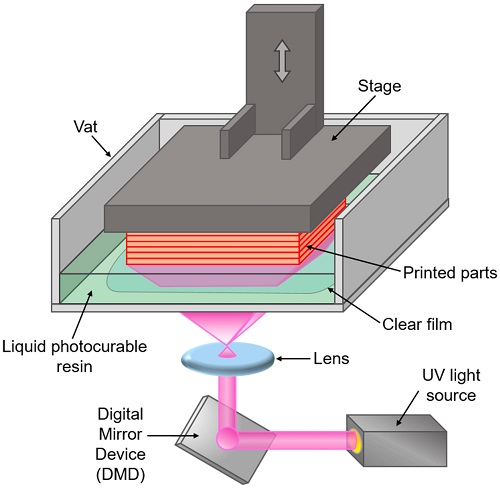

- Stereolithography (SLA): A laser cures liquid resin layer by layer, used for high-precision models and small-scale medical devices.

- Selective Laser Sintering (SLS): Uses lasers to sinter powdered materials such as plastics and metals, typically used for implants and surgical tools.

- Bioprinting: Involves printing with living cells and bioinks to create tissues and potentially organs.

Materials used in medical 3D printing vary depending on the application but include biocompatible polymers, metals, and biological materials (cells, proteins). These materials must adhere to strict safety, performance, and regulatory standards to ensure they are safe for use in medical contexts.

Applications of 3D Printing in Medical Fields

Custom Prosthetics and Implants

3D printing has revolutionized the creation of prosthetics and implants by enabling highly personalized designs tailored to the specific anatomy of individual patients. Unlike traditional manufacturing, where prosthetics are often mass-produced in standard sizes, 3D printing allows for custom-made devices that ensure a better fit, improved functionality, and enhanced aesthetics.

For example, Cochlear has used 3D printing to produce hearing implants that are perfectly matched to the unique shape of a patient's ear canal, improving the overall comfort and effectiveness of the device. Facial prosthetics, dental implants, and joint replacements are also commonly manufactured using 3D printing, providing better results than conventional options.

Surgical Planning and Guides

3D-printed anatomical models of patients' organs or bones can greatly enhance surgical planning. Surgeons can study the model before the procedure, understanding the specific complexities of a patient’s anatomy. This preparation enables more precise surgery, reduces risk, and potentially shortens operation times.

Custom surgical guides made using 3D printing can help position implants or instruments with higher precision, reducing human error during operations. For instance, in joint replacement surgery, a 3D-printed guide can help surgeons precisely align the prosthesis with the surrounding bone structure.

Anatomical Models for Education and Training

In medical education, 3D printing has transformed how students and healthcare professionals learn about human anatomy. Anatomically accurate models of organs, bones, and tissues provide invaluable teaching tools. These models can be made based on real patient data from CT or MRI scans, enabling hands-on training in complex surgeries or rare conditions without risk to patients.

Medical students can practice procedures on 3D-printed models of organs or body parts, gaining experience that would be impossible with traditional cadaver-based methods. Additionally, these models can be customized to reflect variations in human anatomy, offering a deeper, more comprehensive understanding of the human body.

Drug Delivery Systems

3D printing is also changing the way medications are delivered to patients. Personalized drug delivery systems can be created to address specific needs, such as varying release rates or customized dosages. For instance, controlled-release drug carriers can be designed to release medications at a steady pace over an extended period, reducing the need for multiple daily doses and enhancing patient compliance.

Moreover, 3D printing allows for the creation of complex drug formulations that would be difficult to achieve using traditional manufacturing techniques. This includes multi-drug combinations in a single pill or devices designed to release a drug at a precise location within the body.

Benefits and Challenges

Enhanced Patient Outcomes

The ability to create customized devices and tools tailored to the unique needs of each patient leads to significantly improved outcomes. For example, patients receiving personalized prosthetics benefit from better comfort and functionality, while surgical guides help reduce errors and complications. Personalized drug delivery systems also improve treatment efficacy and minimize side effects, leading to better health outcomes overall.

Cost-Efficiency in Healthcare

While the initial investment in 3D printing equipment can be significant, the long-term cost savings are substantial. Custom prosthetics and implants produced through 3D printing are often more affordable than traditional alternatives, as they eliminate the need for large inventories and excess manufacturing processes. Moreover, the ability to produce items on-demand reduces waste and inventory costs.

Additionally, in surgical planning, 3D-printed anatomical models and surgical guides can reduce the likelihood of complications and the need for corrective surgeries, which helps lower healthcare costs in the long run.

Ethical and Regulatory Considerations

Despite the many advantages, 3D printing in medicine presents several ethical and regulatory challenges:

- Regulatory Oversight: Medical devices created through 3D printing must undergo rigorous testing to ensure they meet safety standards. Regulatory bodies, such as the FDA, have yet to establish clear guidelines for 3D-printed medical devices, which can slow down the approval process.

- Material Safety: Ensuring the biocompatibility and safety of materials used in 3D printing is a critical concern. Not all 3D-printing materials are suitable for medical use, especially when they interact with human tissue or are implanted in the body.

- Accessibility: Advanced 3D printing technology may not be available in all healthcare settings, particularly in low-resource areas, which could limit the widespread adoption of these innovations.

Future Prospects

The future of 3D printing in medicine is bright, with several promising developments on the horizon:

- Bioprinting: The creation of functional organs and tissues using living cells is one of the most exciting prospects. While still in the experimental stages, bioprinting holds the potential to revolutionize organ transplantation and regenerative medicine, addressing the global shortage of donor organs.

- Integration with AI and Robotics: Combining 3D printing with artificial intelligence (AI) and robotics will enhance the precision of custom prosthetics, implants, and surgeries, leading to further improvements in patient care.

Advances in Bioprinting

Bioprinting is a particularly exciting field within 3D printing, as it involves the use of living cells and biomaterials (bioinks) to print tissues and potentially organs. Researchers are working to develop bioinks that mimic the human extracellular matrix, providing the necessary environment for cell growth and tissue development. Although bioprinting is still in its early stages, significant strides are being made toward creating functional tissues for medical use, such as skin, cartilage, and even vascular tissues.

One of the most ambitious goals of bioprinting is the creation of fully functional organs, such as livers and kidneys, which could address the organ transplant crisis. While we are not yet at the point of printing fully viable organs for transplant, the progress in tissue engineering is promising.

Integration with Other Technologies

3D printing is poised to benefit even further through integration with other cutting-edge technologies:

- Artificial Intelligence (AI) can analyze patient data to optimize the design of prosthetics or surgical plans.

- Robotics combined with 3D printing can automate complex surgeries and improve precision in implant placement, reducing the risk of human error.

- Machine learning algorithms can help predict the best surgical approaches and the likelihood of success based on historical data, enabling more informed decision-making.

These integrations will enhance the capabilities of 3D printing and expand its applications in medicine.

Predicted Impact on Healthcare Systems

The widespread adoption of 3D printing in healthcare is expected to revolutionize medical systems globally. Personalized care will become more commonplace, addressing individual patient needs more effectively. 3D printing can also help reduce healthcare costs by providing more efficient, on-demand production of medical devices and by reducing complications in surgeries.

As the technology becomes more accessible and affordable, it is expected to become a standard tool in hospitals and clinics, ultimately improving patient care, reducing healthcare disparities, and providing solutions for complex medical conditions.

FAQs

What are the main advantages of 3D printing in medical applications?

- Personalization: Tailored devices and treatments based on individual patient needs.

- Precision: Enhanced accuracy in surgeries and medical procedures.

- Cost-effectiveness: Reduced production costs and waste.

- Innovation: Enabling new medical technologies and treatments.

- Education: Offering realistic anatomical models for training.

- Access: Potential for global access to advanced medical solutions.

What are the challenges associated with 3D printing in medicine?

- Regulatory challenges: Lack of clear guidelines and approval processes for new devices.

- Material safety: Ensuring biocompatibility and safety for medical applications.

- Cost: High upfront costs for equipment and training.

- Skill requirements: Need for specialized knowledge and expertise.

- Quality control: Maintaining consistent and reliable product quality.

- Ethical concerns: Issues related to privacy, data security, and equitable access.

How will 3D printing shape the future of healthcare?

3D printing is expected to drive personalized medicine, improve access to healthcare solutions, accelerate innovation, and reduce costs. Its integration with other technologies such as AI and robotics will further enhance surgical precision and the overall quality of patient care. As the technology continues to evolve, its impact on healthcare systems will be profound.