Custom rapid prototyping has revolutionized the way products are developed, enabling companies to innovate faster, test more thoroughly, and bring products to market with unmatched efficiency. Through the use of cutting-edge technologies like 3D printing and CNC machining, this process allows for the quick creation of physical models directly from CAD designs, streamlining the entire product development cycle.

What Is Rapid Prototyping?

Definition

Rapid prototyping is a set of techniques that enables the fast fabrication of a physical model or assembly using 3D CAD data. It serves as a bridge between conceptual design and mass production, offering the opportunity to test and validate ideas in real-world conditions.

Core Benefits

- Speed: Enables swift design iterations.

- Cost Savings: Avoids costly design flaws in production.

- Improved Product Quality: Facilitates rigorous testing and refinement.

- Enhanced Collaboration: Tangible models promote teamwork and effective stakeholder communication.

- Competitive Edge: Accelerates product launch timelines, keeping companies ahead in the market.

Key Technologies in Rapid Prototyping

1. 3D Printing (Additive Manufacturing)

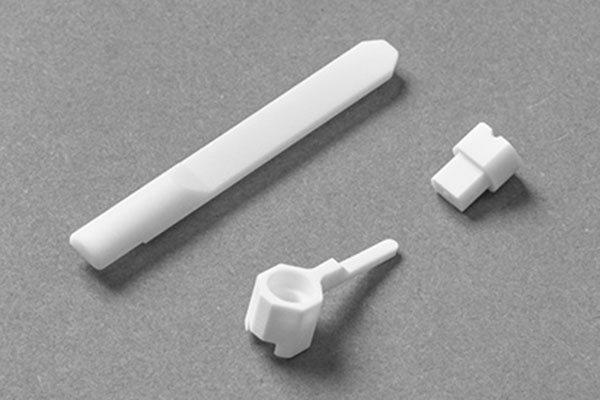

3D printing creates objects layer by layer from a digital model. It supports various materials and allows for the production of intricate designs with exceptional detail.

Advantages:

- Customization: Perfect for creating tailored designs.

- Flexibility: Handles complex geometries with ease.

- Material Options: Ranges from plastics to metals.

- Speed: Ideal for quick prototype production.

Common Types of 3D Printing:

- Fused Deposition Modeling (FDM): Cost-effective and widely used.

- Stereolithography (SLA): High detail and smooth finishes.

- Selective Laser Sintering (SLS): Durable prototypes with complex designs.

2. CNC Machining (Subtractive Manufacturing)

CNC machining removes material from a solid block to achieve the desired shape. It excels in creating robust, precise prototypes suitable for functional testing.

Advantages:

- Precision: Produces highly accurate components.

- Material Versatility: Compatible with metals, plastics, and more.

- Durability: Creates strong prototypes for rigorous use.

- Surface Finish: Achieves polished, functional parts.

Steps in Custom Rapid Prototyping

From Idea to Prototype

- Conceptualization: Define objectives and functionality.

- CAD Modeling: Develop detailed designs using 3D CAD software.

- Material Selection: Choose suitable materials based on application needs.

- Prototype Creation: Fabricate using 3D printing or CNC machining.

- Testing and Validation: Assess performance and identify improvements.

- Iteration: Make design adjustments and produce subsequent versions.

- Finalization: Prepare for production with an optimized design.

Importance of Material Selection

The choice of material can significantly affect prototype performance and functionality.

Key Factors to Consider:

- Strength and Durability: Essential for prototypes undergoing stress tests.

- Thermal Properties: Crucial for high-temperature environments.

- Cost Efficiency: Balancing material performance with budget constraints.

- Chemical Resistance: Required for exposure to harsh substances.

Common Materials in Prototyping:

- Plastics: ABS, PLA, and Nylon for versatility.

- Metals: Aluminum and Titanium for strength and durability.

- Composites: Carbon fiber for lightweight, high-strength applications.

- Resins: SLA and DLP for high-detail prototypes.

How Rapid Prototyping Drives Product Development

1. Iterative Design and Testing

Custom rapid prototyping supports continuous iteration, enabling developers to refine designs based on real-world testing. This iterative approach reduces risk and enhances the final product’s quality.

2. Enhanced Collaboration

Physical prototypes bridge communication gaps, allowing teams and stakeholders to visualize, evaluate, and discuss designs effectively.

3. Faster Time-to-Market

By accelerating the testing and validation process, rapid prototyping helps companies shorten development cycles and launch products ahead of competitors.

Case Studies: Real-World Impact

1. Medical Devices

- Example: Ottobock used 3D printing to create custom prosthetics tailored to individual patients, reducing production time and improving outcomes.

- Impact: Enabled quicker iterations of surgical instruments, enhancing precision and safety.

2. Automotive Innovation

- Example: Ford employed CNC machining and 3D printing to prototype new car models.

- Impact: Streamlined testing for aerodynamics and ergonomics, reducing the overall development timeline.

3. Consumer Electronics

- Example: A tech giant used SLA 3D printing to prototype sleek, high-detail laptop designs with innovative cooling systems.

- Impact: Shortened design cycles, leading to a successful product launch.

Future of Rapid Prototyping

Technological Advancements

- AI Integration: Enhances design and testing with predictive analytics.

- Hybrid Manufacturing: Combines additive and subtractive techniques for optimized results.

- Smart Materials: Innovations like shape-memory alloys offer new possibilities.

Sustainability Goals

- Focus on using biodegradable materials.

- Energy-efficient manufacturing processes.

Conclusion

Custom rapid prototyping is transforming industries by enabling faster innovation, more thorough testing, and seamless collaboration. With advancements in 3D printing, CNC machining, and materials science, the future of rapid prototyping promises even greater possibilities. Companies adopting these technologies are not only improving their products but also redefining the speed and efficiency of product development.