Few things derail production like a die that cracks mid-run or a mold that warps under the heat of molten metal. For manufacturers working with hot metals or high-temperature plastics, these failures aren’t just inconvenient—they’re costly, eating into profits and delaying deliveries. That’s where H13 (SKD61) comes in. Renowned as the workhorse of hot work tool steels, H13 and its Japanese equivalent SKD61 are engineered to thrive in the harshest high-temperature environments, from die casting to hot forging. In this guide, we’ll explore how H13 (SKD61) solves these critical pain points, why it’s trusted across industries, and how to maximize its performance in your molds.

Material Overview of H13 (SKD61)

H13 tool steel and its Japanese counterpart SKD61 are the backbone of hot work applications, with a heritage of reliability that spans decades:

- Hot work tool steel classification: Both H13 and SKD61 belong to the chromium-molybdenum-vanadium family of hot work steels, designed to withstand extreme heat and repeated thermal cycling.

- Chemical composition: H13 typically contains 0.38-0.45% carbon, 4.75-5.50% chromium, 1.10-1.75% molybdenum, and 0.80-1.20% vanadium. SKD61 is nearly identical but with slightly lower silicon (≤0.30%), enhancing its polishability for precision molds.

- Grade specifications: H13 adheres to ASTM A681 standards, while SKD61 follows JIS G4404, ensuring consistent quality across manufacturers. Both are supplied in the annealed condition (200-250 HB) for easy machining.

- Industry applications: From automotive die casting to aerospace hot forging, H13 (SKD61) is the go-to choice for applications where temperatures exceed 1,000°F (538°C) and tools face heavy mechanical stress.

Properties and Characteristics of H13 (SKD61)

The properties and characteristics of H13 (SKD61) set it apart as a versatile performer in high-temperature environments:

- High-temperature strength: H13 retains 80% of its room-temperature strength at 1,000°F (538°C), resisting deformation under the extreme pressure of hot forging (up to 50,000 psi).

- Hot hardness: At 1,000°F, H13 maintains a hardness of 45-50 HRC—far higher than cold work steels like D2 (30-35 HRC at the same temperature), ensuring tools keep their shape during prolonged use.

- Resistance to thermal fatigue: Repeated heating and cooling (common in die casting) create microcracks in lesser steels, but H13 (SKD61) resists this. Testing shows it withstands 500+ thermal cycles (1,000°F to 70°F) without cracking, 3x more than D2.

- Thermal conductivity: With a thermal conductivity of 28-32 W/m·K, H13 dissipates heat 40% faster than cold work steels, preventing hot spots that cause uneven wear.

- Dimensional stability at high temperatures: H13 expands minimally under heat (thermal expansion coefficient: 11.5 × 10⁻⁶/°C), maintaining tight tolerances in precision hot stamping molds.

- Red hardness: This ability to retain hardness after prolonged heat exposure makes H13 ideal for continuous operations like hot rolling, where tools stay hot for hours.

Heat Treatment and Processing of H13 (SKD61)

Proper heat treatment and processing are critical to unlocking H13 (SKD61)’s full potential—mistakes here can halve tool life:

- Annealing process: Heat to 1,500-1,550°F (815-845°C), hold for 2-4 hours, then cool slowly (≤50°F/hour) to 1,000°F (538°C). This softens the steel to 200-250 HB, making it easy to machine with carbide tools.

- Hardening temperatures: H13 achieves optimal properties when hardened at 1,850-1,875°F (1,010-1,024°C), held for 30-60 minutes. SKD61 uses the same range, with slightly longer holding times for uniform heating.

- Tempering cycles: Temper at 1,000-1,100°F (538-593°C) for 2-4 hours, repeating once for maximum toughness. This results in a final hardness of 44-48 HRC—perfect for balancing strength and resistance to thermal cracking.

- Quenching methods: Vacuum quenching is preferred, cooling the steel at 200-300°F/second to form a uniform martensitic structure without oxidation. Oil quenching works for simple shapes but may cause uneven cooling.

- Surface treatments: Nitriding adds a 5-10 micron hard layer, boosting surface hardness to 65-70 HRC and improving wear resistance at elevated temperatures by 40%—ideal for die casting molds.

- EDM performance: H13 (SKD61) handles Electrical Discharge Machining well, though the recast layer (0.0001-0.0003 inches) must be removed to prevent cracking in high-stress areas.

Applications in Mold Making: Where H13 (SKD61) Excels

H13 (SKD61) shines in a wide range of applications in mold making that demand durability under heat and pressure:

- Die casting molds: For aluminum and magnesium die casting, H13 (SKD61) resists the cyclic heat of molten metal (660-1,200°F) and chemical attack from mold release agents, lasting 50,000-150,000 cycles.

- Hot forging dies: Shaping red-hot metal billets (1,200-1,800°F) requires extreme toughness—H13 delivers, withstanding the impact of 50,000+ psi presses without cracking.

- Hot stamping dies: Automotive manufacturers rely on H13 to shape boron steel blanks heated to 900°C, forming crash-resistant parts with tight tolerances.

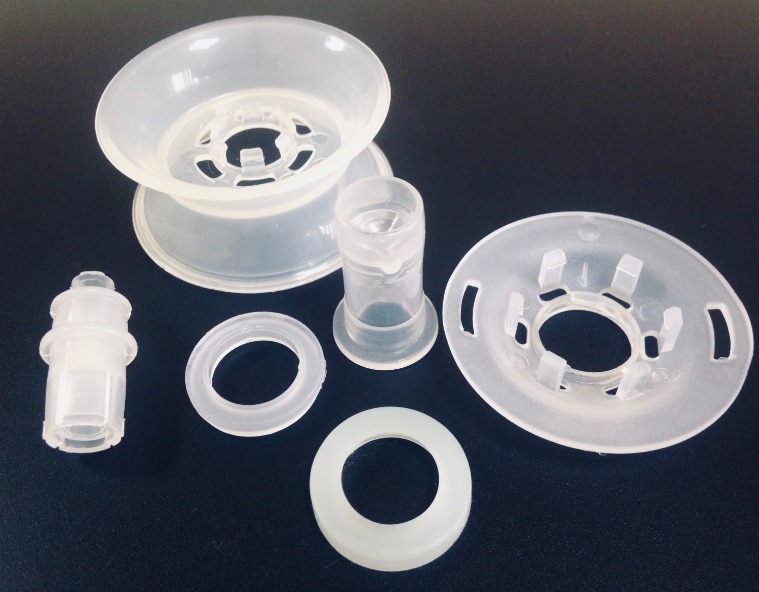

- Injection molding for high-temperature plastics: SKD61’s superior polishability makes it ideal for molds processing PEEK and other high-performance resins (processed at 700-800°F), maintaining a mirror finish for 100,000+ cycles.

- Hot extrusion tools: Extruding stainless steel and titanium (die temperatures 1,500°F+) demands H13’s high-temperature strength, with tool life 2-3x longer than cold work steels.

Performance and Advantages of H13 (SKD61)

The performance and advantages of H13 (SKD61) make it a cost-effective choice despite its higher upfront cost:

- Longer mold life: In aluminum die casting, H13 molds last 100,000+ cycles—10x longer than D2, which fails after 10,000 cycles due to thermal cracking.

- Reduced downtime: With better resistance to thermal fatigue, H13 (SKD61) requires 30-50% fewer replacements than lesser steels, keeping production lines running.

- Improved dimensional accuracy: H13’s dimensional stability at high temperatures ensures parts stay within ±0.0005 inches, reducing scrap rates by 20-25% in precision applications.

- Cost-effectiveness: While H13 costs 2-3x more than D2 upfront, its 10x longer life lowers total cost of ownership by 40-60% over a year of high-volume production.

- Better toughness compared to other hot work steels: H13 offers 15-20% better impact resistance than high-vanadium hot work steels, making it more forgiving in applications with moderate impact.

Comparison with Other Steels

How does H13 (SKD61) stack up against alternatives? Here’s a detailed comparison:

| Steel Grade | Hardness (HRC) | Hot Hardness (1,000°F) | Thermal Fatigue Resistance | Cost (Relative) | Best For |

| H13/SKD61 | 44-48 | 45-50 | Excellent | Medium-High | General hot work (die casting, forging) |

| D2 | 57-62 | 30-35 | Poor | Medium | Cold work only |

| SKD11 | 57-61 | 35-40 | Fair | Medium | Low-heat cold work |

| 1.2344 (DIN) | 44-48 | 46-51 | Excellent | High | European hot work standards |

| Powder metallurgy (ASP-2059) | 48-52 | 48-53 | Excellent | Very High | Extreme-temperature applications |

- H13 vs. D2: D2 offers superior room-temperature wear resistance but fails quickly in hot applications, making it unsuitable for die casting or forging.

- H13 vs. SKD11: SKD11 (a cold work steel) can’t match H13’s high-temperature strength—it warps at 800°F, while H13 thrives at 1,200°F+.

- Cost comparison: H13 (SKD61) costs less than specialty hot work steels like powder metallurgy grades but more than cold work steels. Its performance in hot applications justifies the investment.

Maintenance and Service of H13 (SKD61) Tools

Proper maintenance and service can extend H13 (SKD61)’s life by 2-3x:

- Preventive maintenance: Clean molds after each shift to remove oxide scale, which accelerates wear. Apply a high-temperature anti-rust coating during storage.

- Reconditioning: Worn H13 dies can be reground and re-tempered 3-5 times, restoring their dimensions and hardness. This costs 50-70% less than replacing the tool.

- Crack repair: Small thermal cracks can be welded with H13 filler rod, followed by stress-relief annealing at 1,000°F to restore toughness.

- Tool sharpening: For hot shearing tools, sharpen when edge wear reaches 0.002 inches using CBN wheels to avoid overheating and softening the steel.

Industry Standards and Specifications

H13 (SKD61) is governed by strict industry standards and specifications to ensure quality:

- ASTM standards: ASTM A681 defines H13’s chemical composition, heat treatment, and mechanical properties, ensuring consistency across manufacturers.

- JIS standards: JIS G4404 outlines SKD61’s requirements, with tight controls on sulfur (≤0.030%) to prevent brittleness.

- Quality certifications: ISO 9001-certified suppliers (like Yigu Technology) perform rigorous testing, including ultrasonic inspection to detect internal defects and hardness testing to verify heat treatment.

- Material testing methods: Charpy impact tests (at room and elevated temperatures) confirm toughness, while thermal fatigue testing ensures resistance to cyclic heating.

Yigu Technology’s Perspective

At Yigu Technology, H13 (SKD61) is our go-to for 90% of hot work mold projects. We’ve found its balance of toughness, high-temperature strength, and cost-effectiveness unmatched for die casting and hot forging. Our in-house heat treatment experts optimize tempering cycles—for example, 1,050°F for 4 hours for automotive die casting molds—to maximize thermal fatigue resistance. Clients switching to H13 from lesser steels typically see 50% longer tool life and 30% fewer production delays, making it a smart investment for high-volume operations.

FAQs

- Can H13 (SKD61) be used for cold work applications?

While possible, H13’s lower room-temperature hardness (44-48 HRC) makes it less wear-resistant than cold work steels like D2, leading to shorter tool life in cold stamping or extrusion.

- What’s the difference between H13 and SKD61?

Chemically, they’re nearly identical, but SKD61 has lower silicon, improving polishability for precision molds. H13 follows ASTM standards, while SKD61 adheres to JIS.

- How does nitriding affect H13 (SKD61) performance?

Nitriding creates a hard surface layer (65-70 HRC) that improves wear resistance at elevated temperatures by 40%, ideal for die casting molds where molten metal contacts the tool repeatedly.