Manufacturers producing ultra-precision parts—such as optical lenses, microelectronics, or medical devices—face a hidden enemy: temperature fluctuations. Even minor changes in ambient temperature or molding heat can cause traditional mold materials to expand or contract, leading to part dimensional errors as small as 0.001 mm. These tiny inconsistencies can render high-precision components useless, resulting in costly scrap and production delays. This is where Invar (Fe-Ni36) revolutionizes mold making. With one of the lowest thermal expansion rates of any metal, Invar maintains near-perfect dimensional stability across wide temperature ranges, solving the critical pain point of precision loss due to heat. In this guide, we’ll explore how Invar ensures consistent part quality in the most demanding applications, its unique properties, and how to leverage its capabilities effectively.

Introduction to Invar (Fe-Ni36)

Invar (Fe-Ni36) is a nickel-iron alloy celebrated for its exceptional dimensional stability, making it indispensable for high-precision mold applications:

- Definition: Invar (short for “invariable”) is an alloy composed of 36% nickel and 64% iron, with trace amounts of cobalt (typically 0.5-1%) to enhance stability. Its name reflects its near-constant dimensions across temperature changes, a property discovered by Swiss physicist Charles Édouard Guillaume in 1896.

- Standard specifications: Invar complies with ASTM F1684 and ISO 13973 standards, which 严格控制 (strictly control) its chemical composition and thermal expansion properties. These standards ensure a thermal expansion coefficient of ≤1.2 µm/m·°C between -50°C and 100°C, guaranteeing consistent performance.

- Supplier brands: Leading manufacturers include Aperam (France), ThyssenKrupp (Germany), and Chinese suppliers like Baosteel. These brands produce Invar in sheets, plates, and custom shapes optimized for precision mold components.

- Industry usage: Invar is used in 5-8% of high-precision molds, primarily for optical parts, microelectronics, and medical devices where dimensional tolerance requirements are ≤±0.001 mm. Its ability to maintain stability in temperature-varying environments makes it irreplaceable in these fields.

- Comparison with other mold materials: Invar’s thermal expansion (1.2 µm/m·°C) is 1/10 that of steel (11-12 µm/m·°C) and 1/20 that of aluminum (23-24 µm/m·°C). While it’s less wear-resistant than steel and more expensive, its dimensional stability justifies the cost for applications where precision is non-negotiable.

Properties of Invar (Fe-Ni36)

The properties of Invar (Fe-Ni36) make it the gold standard for dimensional stability in mold making:

- Low thermal expansion coefficient: At 1.2 µm/m·°C, Invar’s thermal expansion is among the lowest of any commercial metal. Even when heated from 20°C to 100°C, a 100 mm Invar mold component expands by only 0.0096 mm—compared to 0.088 mm for steel and 0.2 mm for aluminum under the same conditions.

- Good dimensional stability: Invar retains its shape not just under temperature changes, but also over time. Long-term aging tests show less than 0.0005% dimensional change after 10 years, critical for molds used in multi-year production runs.

- High strength: With a tensile strength of 450-550 MPa, Invar provides sufficient strength to withstand typical molding pressures (up to 15,000 psi), ensuring structural integrity in precision molds.

- Good corrosion resistance: Invar resists rust and mild corrosion better than carbon steel, though it’s less resistant than stainless steel. A thin nickel plating can enhance its resistance in humid production environments.

- Thermal conductivity: Invar has a thermal conductivity of 12 W/m·K, significantly lower than steel (40-50 W/m·K) and aluminum (160-200 W/m·K). This low conductivity requires specialized cooling design but minimizes heat-related dimensional changes.

- Magnetic properties: Invar is ferromagnetic, but its magnetic permeability is low enough for most non-magnetic applications. For fully non-magnetic molds, modified Invar grades with chromium additions are available.

Applications of Invar (Fe-Ni36) in Mold Making

Invar (Fe-Ni36) excels in applications where even microscopic dimensional changes are unacceptable:

- Optical molds: For lenses, prisms, and laser components requiring ±0.0005 mm tolerances, Invar molds ensure consistent part geometry regardless of ambient or molding temperatures. Its stability prevents optical distortion caused by uneven cooling.

- Microelectronics molds: Molds for semiconductor components, sensor housings, and micro-connectors rely on Invar to maintain the tiny, precise features (0.1-1 mm) critical for electronic performance.

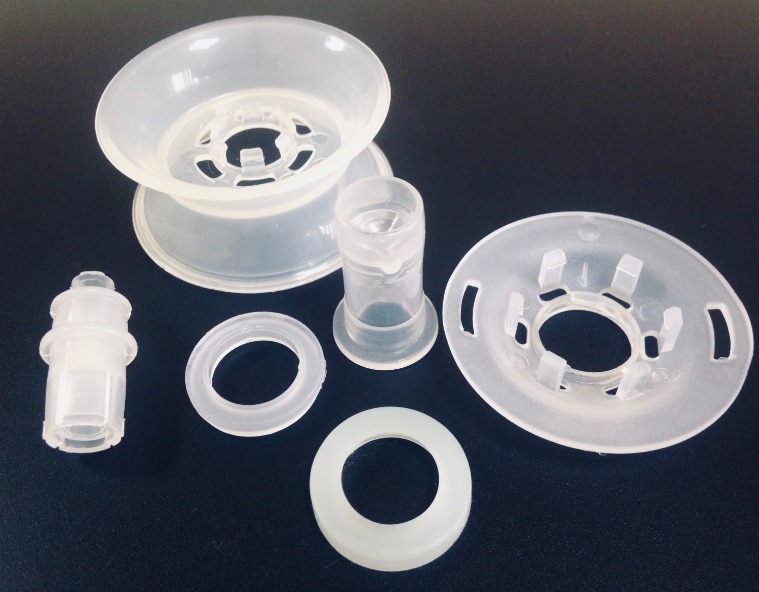

- Medical device molds: Invar produces precision parts like catheter tips, endoscope components, and surgical tools, where dimensional consistency directly impacts patient safety and device functionality.

- Automotive precision parts: Invar is used in molds for fuel injection nozzles, sensor housings, and other automotive components where tight tolerances ensure proper fit and performance.

- High-precision prototype molds: For validating designs with extreme tolerance requirements, Invar prototypes provide accurate data on part behavior, reducing the risk of expensive production mold revisions.

Machining and Fabrication of Invar (Fe-Ni36)

Machining and fabrication of Invar require careful techniques due to its unique properties:

- Precision machining: Invar machines similarly to medium-carbon steel but with higher tool wear due to its work-hardening tendency. Carbide tools with sharp cutting edges are recommended, with cutting speeds of 100-150 SFM to minimize heat buildup.

- CNC milling: 3-axis and 5-axis CNC milling achieve tight tolerances (±0.0001 inches) in Invar, though rigid machine setups are critical to avoid vibration. Coolant is essential to prevent work hardening and maintain dimensional accuracy.

- EDM (Electrical Discharge Machining): EDM is ideal for intricate Invar components, as it avoids the heat and pressure of traditional machining that can cause micro-deformations. Wire EDM achieves surface finishes as smooth as Ra 0.05 μm.

- Grinding: Invar grinds well with aluminum oxide wheels, though slower feed rates (10-15 m/min) are needed to prevent overheating. A 600-grit wheel ensures flatness within 0.001 mm/m.

- Surface finishing: Invar polishes to Ra 0.02-0.05 μm with 800-1200 grit sandpaper and diamond pastes. This smooth surface prevents part sticking and ensures easy release in molding.

- Machining challenges: Invar’s low thermal conductivity causes heat to accumulate at the cutting edge, accelerating tool wear. Work hardening can also make secondary machining difficult, so it’s best to machine to final dimensions in one setup.

Maintenance and Repair of Invar (Fe-Ni36) Molds

Proper maintenance and repair preserve Invar’s dimensional stability and extend mold life:

- Mold cleaning: Clean Invar surfaces with mild detergents and soft cloths to remove plastic residue. Avoid abrasive cleaners, which can scratch the surface and create stress points that compromise stability.

- Surface treatment: A thin (2-5 μm) nickel or chrome plating enhances Invar’s wear resistance without significantly affecting its thermal expansion properties. This is recommended for molds running >100,000 cycles.

- Repair welding: Invar can be TIG welded with matching nickel-iron filler wire. Post-weld heat treatment (annealing at 600-650°C for 1 hour) relieves stresses and restores dimensional stability, critical for maintaining precision.

- Preventive maintenance: Inspect Invar molds monthly for signs of wear or deformation, using laser interferometers to check for dimensional changes as small as 0.0001 mm. This early detection prevents costly part defects.

- Inspection: Use coordinate measuring machines (CMM) with ±0.0001 mm accuracy to verify mold dimensions after cleaning or repair. Thermal cycling tests (from 20°C to 100°C) ensure the mold retains its stability.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends Invar (Fe-Ni36) for clients with extreme precision requirements. We’ve used it to produce optical molds with ±0.0005 mm tolerances, where traditional materials failed due to temperature fluctuations. While Invar’s machining costs are 2-3x higher than steel, its ability to eliminate scrap from dimensional errors justifies the investment. Our team uses precision EDM and grinding to achieve Invar’s tight tolerances, with post-machining annealing to ensure stability. For applications like microelectronics and medical devices, Invar isn’t just a choice—it’s a necessity to meet the strictest quality standards.

FAQs

- When is Invar (Fe-Ni36) necessary instead of steel for mold making?

Invar is necessary when part tolerances are ≤±0.001 mm, or when ambient/molding temperatures vary by more than 5°C. For less demanding tolerances (±0.005 mm or higher), steel is more cost-effective.

- How does Invar’s low thermal conductivity affect mold cooling?

Invar’s low thermal conductivity (12 W/m·K) slows cooling, potentially extending cycle times by 10-20%. To mitigate this, design molds with more cooling channels or use conformal cooling to improve heat transfer.

- Can Invar molds be used with abrasive plastics like glass-filled nylon?

Invar has moderate wear resistance, so it’s not ideal for highly abrasive materials. For such applications, use Invar for the precision-critical areas and carbide inserts for high-wear zones, balancing stability and durability.