A precision manufacturing company is a critical partner for businesses across aerospace, medical, automotive, and electronics sectors, specializing in producing high-tolerance components and assemblies with exceptional accuracy. Whether you need custom precision machining parts, electro-mechanical assemblies, or specialized attachments, selecting the right precision manufacturing company directly impacts product quality, production efficiency, and market competitiveness. This guide is tailored for procurement managers, product engineers, and business owners seeking to understand the core value of precision manufacturing company services, key selection criteria, industry applications, and best practices for successful collaboration. We integrate real-world case studies, verifiable industry data, and expert insights to help you make informed decisions and maximize the value of your partnership with a precision manufacturing company.

What Is a Precision Manufacturing Company? Core Definition & Value

A precision manufacturing company specializes in the production of components, parts, and assemblies that require strict adherence to dimensional tolerances (often as tight as ±0.0001 inches), surface finish standards, and material integrity. Unlike general manufacturing firms, precision manufacturing company operations are built around advanced technologies (CNC machining, wire EDM, 3D printing) and rigorous quality control systems to ensure consistency and accuracy across high-volume or custom production runs.

The core value of partnering with a precision manufacturing company includes: Ultra-Precision Production: Ability to manufacture parts with complex geometries and tight tolerances that general manufacturing cannot achieve, critical for high-performance applications (e.g., medical implants, aerospace components).Material Expertise: Proficiency in processing a wide range of advanced materials (titanium, Inconel, ceramics, composites) that require specialized handling and machining techniques.Quality Assurance: Implementation of industry-leading quality control processes (ISO 9001, AS9100, FDA compliance) to ensure parts meet regulatory and customer specifications.Scalability & Flexibility: Capacity to handle both low-volume custom orders and high-volume production runs, adapting to changing customer needs and market demands.Cost Optimization: Reduction of material waste, rework, and production downtime through precise process control, ultimately lowering total manufacturing costs.

Industry Insight: According to a 2026 report by Markets and Markets, the global precision manufacturing market is projected to reach $586.7 billion by 2030, growing at a CAGR of 5.9%. The growth is driven by increasing demand for high-precision components in automotive EVs, medical devices, and aerospace, with precision manufacturing company services accounting for 65% of the market share.

Key Capabilities of a Leading Precision Manufacturing Company

Top-tier precision manufacturing company operations are defined by a comprehensive set of capabilities that enable them to meet diverse customer needs. Below are the core capabilities to look for when evaluating a precision manufacturing company:

1. Precision CNC Machining

CNC (Computer Numerical Control) machining is the backbone of most precision manufacturing company operations, enabling automated, high-precision cutting, milling, turning, and drilling. Key CNC capabilities include:5-Axis CNC Machining: Ability to process complex parts from multiple angles in a single setup, reducing production time and improving accuracy. Ideal for aerospace and medical components.Swiss-Style CNC Turning: Specialized for small, high-precision parts (e.g., medical screws, electronic connectors) with tight tolerances and excellent surface finish.Wire EDM Machining: Uses electrical discharge to cut hard materials (tungsten, carbide) with ultra-precision, ideal for complex shapes and thin-walled components.

Case Study: A leading precision manufacturing company partnered with an aerospace firm to produce 5-axis machined turbine blades. Using advanced CNC milling technology, the company achieved tolerances of ±0.0005 inches, reduced material waste by 35%, and increased production efficiency by 40% compared to the client’s previous supplier.

2. Assembly Services

Beyond component manufacturing, top precision manufacturing company operations offer end-to-end assembly services, ensuring seamless integration of precision parts into finished products. Key assembly capabilities include: Wire Harness & Cable Assembly: Precision assembly of electrical wire harnesses and cables for automotive, aerospace, and electronic applications, requiring strict adherence to wiring diagrams and safety standards.Electro-Mechanical Assembly: Integration of mechanical components with electrical systems (motors, sensors, controllers) to create functional sub-assemblies or finished products.Kitting: Preparation of custom kits containing all necessary precision parts and components for streamlined assembly by the client, reducing inventory costs and production time.

3. Custom Fabrication & Prototyping

A versatile precision manufacturing company should offer custom fabrication and prototyping services to support product development cycles. This includes: Custom Part Design Support: Collaboration with clients to optimize part designs for manufacturability, reducing costs and improving performance.Rapid Prototyping: Use of 3D printing, CNC machining, and other technologies to produce functional prototypes quickly, enabling iterative testing and design refinement.Low-Volume Custom Production: Ability to produce small batches of custom parts for niche applications or product launches, without the need for expensive tooling.

4. Quality Control & Inspection

Quality control is non-negotiable for a precision manufacturing company. Leading firms implement comprehensive inspection processes and use advanced equipment to ensure part quality: Advanced Inspection Equipment: Coordinate Measuring Machines (CMMs), optical comparators, surface roughness testers, and X-ray inspection systems for accurate dimensional and material analysis.Statistical Process Control (SPC): Real-time monitoring of production processes to identify and correct variations before they affect part quality.Compliance Certifications: Adherence to industry standards such as ISO 9001 (general quality), AS9100 (aerospace), ISO 13485 (medical), and FDA regulations for medical device manufacturing.

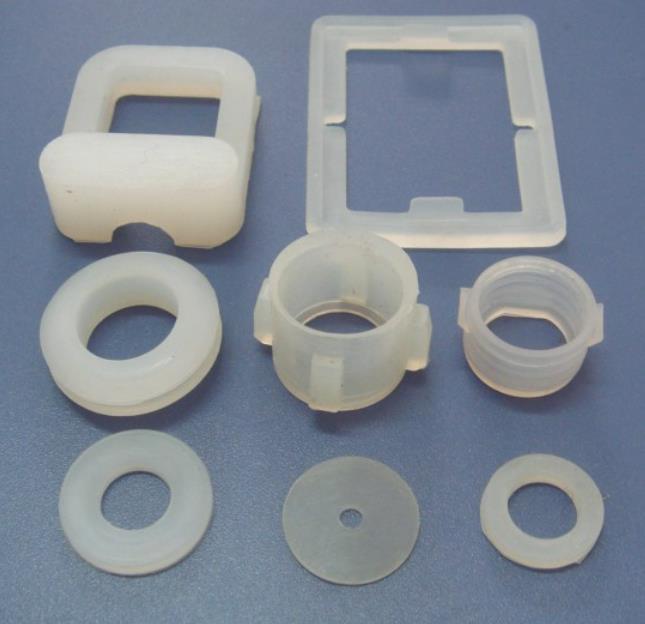

Key Products & Applications of Precision Manufacturing Company Services

Precision manufacturing company services support a wide range of industries, producing critical components and products that drive innovation and performance. Below are the most common products and their industry applications:

| Product Category | Examples | Target Industry | Key Requirements |

|---|---|---|---|

| Precision Machined Parts | Engine components, turbine blades, medical implants, electronic connectors | Automotive, Aerospace, Medical, Electronics | Tight tolerances (±0.0001–±0.001 inches), high surface finish, material biocompatibility (medical) |

| Heavy-Duty Attachments | Grapples, rakes, stump buckets, custom construction attachments | Construction, Agriculture, Mining | High strength, durability, resistance to wear and corrosion |

| Electro-Mechanical Assemblies | Sensor modules, motor assemblies, control panels | Automotive, Electronics, Industrial Machinery | Precise component alignment, electrical conductivity, reliability |

| Wire Harnesses & Cables | Automotive wiring harnesses, aerospace cable assemblies, medical device wiring | Automotive, Aerospace, Medical | Fire resistance, vibration resistance, compliance with safety standards |

| Custom Prototypes | New product prototypes, functional test parts, design validation components | All Industries (Product Development) | Fast turnaround, design flexibility, accurate representation of production parts |

Industry-Specific Applications Deep Dive

Medical Device Industry

Precision manufacturing company services are critical for medical device production, where part accuracy and biocompatibility directly impact patient safety. Key applications include hip/knee replacements, dental implants, surgical scalpels, and MRI machine components. A reputable precision manufacturing company serving the medical sector must comply with FDA regulations and ISO 13485 standards, ensuring parts are made from biocompatible materials (titanium, stainless steel) with ultra-precise tolerances.

Automotive Industry

In the automotive sector, precision manufacturing company operations produce high-precision components for EVs (battery enclosures, motor parts), advanced driver-assistance systems (ADAS) sensors, and transmission components. These parts require tight tolerances to ensure performance, efficiency, and safety. For example, a precision manufacturing company producing EV motor shafts must achieve tolerances of ±0.0005 inches to minimize vibration and maximize energy efficiency.

Construction & Agriculture Industry

Precision manufacturing company services for construction and agriculture focus on heavy-duty attachments (grapples, rakes, stump buckets) and structural components. These products require high strength, durability, and resistance to harsh environments. A leading precision manufacturing company in this space uses advanced welding techniques, heat treatment, and quality inspection to ensure attachments can withstand heavy loads and frequent use.

How to Choose the Right Precision Manufacturing Company: 7 Key Criteria

Selecting the right precision manufacturing company is a critical decision that requires careful evaluation of multiple factors. Below are the 7 key criteria to guide your selection process:

1. Technical Capabilities & Equipment

Evaluate the precision manufacturing company’s technical capabilities and equipment to ensure they can meet your specific needs. Key questions to ask: Do they have the necessary CNC machines (5-axis, Swiss-style) and inspection equipment (CMMs, optical comparators) for your project?Can they process the materials required for your parts (e.g., titanium, composites)?Do they offer the assembly services (wire harness, electro-mechanical) you need, or only component manufacturing?

2. Quality Certifications & Compliance

Quality certifications are a testament to aprecision manufacturing company’s commitment to consistency and compliance. Prioritize companies with: ISO 9001 certification (general quality management).Industry-specific certifications (AS9100 for aerospace, ISO 13485 for medical, FDA compliance for medical devices).Documented quality control processes and a track record of passing customer audits.

3. Experience & Industry Expertise

Look for a precision manufacturing company with experience in your industry and with similar projects. Key indicators of expertise include: Case studies or references from clients in your industry.A team of skilled engineers and technicians with industry-specific knowledge.Understanding of industry regulations and requirements (e.g., aerospace AS9100, medical FDA).

Case Study: A medical device startup needed a precision manufacturing company to produce custom surgical instruments. They selected a company with 15+ years of medical manufacturing experience, ISO 13485 certification, and a portfolio of similar projects. The partnership resulted in on-time delivery of high-quality instruments that met FDA requirements, enabling the startup to launch its product successfully.

4. Production Capacity & Lead Times

Assess the precision manufacturing company’s production capacity to ensure they can handle your order volume and meet your lead time requirements. Key considerations: Can they scale production from prototyping to high-volume manufacturing?What are their typical lead times for custom orders? Do they offer expedited services if needed?Do they have contingency plans for production disruptions (e.g., equipment breakdowns, supply chain issues)?

5. Cost Competitiveness

While cost should not be the sole deciding factor, it is an important consideration. Evaluate the precision manufacturing company’s pricing structure to ensure it aligns with your budget. Look for: Transparent pricing with no hidden fees.Willingness to provide detailed quotes and explain cost drivers (material, labor, tooling).Ability to optimize designs for manufacturability to reduce costs without compromising quality.

6. Communication & Customer Service

Effective communication is critical for a successful partnership with aprecision manufacturing company. Look for a company that: Assigns a dedicated account manager or project engineer to your project.Provides regular updates on production progress.Responds promptly to questions and addresses concerns quickly.Is willing to collaborate on design optimization and problem-solving.

7. Location & Supply Chain Resilience

Consider the precision manufacturing company’s location and supply chain resilience. Key factors: Proximity to your business can reduce shipping costs and lead times.A diversified supply chain for raw materials to minimize the impact of shortages or price volatility.Compliance with ethical sourcing and sustainability standards (e.g., ISO 14001 for environmental management).

Best Practices for Collaborating with a Precision Manufacturing Company

Once you’ve selected a precision manufacturing company, following these best practices will help ensure a successful collaboration:

1. Provide Clear & Detailed Specifications

Supply the precision manufacturing company with detailed drawings, 3D models, and specifications (tolerances, surface finish, material requirements) to avoid misunderstandings. Use industry-standard file formats (STEP, IGES) and clearly mark critical features.

2. Collaborate on Design for Manufacturability (DFM)

Engage the precision manufacturing company’s engineering team early in the design process to optimize parts for manufacturability. DFM reviews can identify potential issues (e.g., tight tolerances that are difficult to achieve, material selection inconsistencies) and suggest modifications to reduce costs and improve production efficiency.

3. Establish Clear Quality Requirements

Define clear quality requirements and inspection criteria upfront. Work with the precision manufacturing company to establish acceptance criteria for first-article inspection (FAI) and in-process inspections. Request regular quality reports to ensure compliance.

4. Maintain Open Communication

Schedule regular check-ins with the precision manufacturing company to review production progress, address any issues, and provide feedback. Prompt communication can prevent delays and ensure the project stays on track.

5. Plan for Long-Term Partnership

Building a long-term relationship with a precision manufacturing company can lead to better service, improved quality, and cost savings over time. A trusted partner will gain a deeper understanding of your business needs and can proactively suggest improvements to your manufacturing processes.

FAQ About Precision Manufacturing Company

Q1: What is a precision manufacturing company? A1: A precision manufacturing company specializes in producing high-tolerance components, parts, and assemblies with exceptional accuracy (tolerances as tight as ±0.0001 inches). They use advanced technologies (CNC machining, wire EDM) and rigorous quality control systems to meet strict industry standards and customer requirements, serving sectors like aerospace, medical, automotive, and electronics.

Q2: What capabilities should I look for in a precision manufacturing company? A2: Key capabilities include precision CNC machining (5-axis, Swiss-style), wire EDM, assembly services (wire harness, electro-mechanical, kitting), custom fabrication/prototyping, and comprehensive quality control (CMM inspection, SPC). They should also have industry-specific certifications (ISO 9001, AS9100, ISO 13485) and experience in your target sector.

Q3: How do precision manufacturing companies ensure part quality? A3: Precision manufacturing company operations use advanced inspection equipment (CMMs, optical comparators) and implement quality control processes like Statistical Process Control (SPC) to monitor production in real time. They also adhere to industry certifications (ISO 9001, AS9100) and conduct first-article inspections (FAI) and in-process inspections to ensure parts meet specifications.

Q4: What industries do precision manufacturing companies serve? A4: Precision manufacturing company services support a wide range of industries, including aerospace, medical devices, automotive (especially EVs), electronics, construction, agriculture, and industrial machinery. They produce critical components like turbine blades, medical implants, EV motor parts, and custom construction attachments.

Q5: How much does it cost to work with a precision manufacturing company? A5: Costs vary based on part complexity, material type, order volume, and lead time requirements. Simple precision parts may cost $5–$50 per unit, while complex components (e.g., aerospace turbine blades, medical implants) can cost $100–$1,000+ per unit. A reputable precision manufacturing company will provide a detailed quote with transparent pricing.

Q6: What is the typical lead time for a precision manufacturing company? A6: Lead times vary by project complexity and order volume. Prototyping or small-batch orders may take 1–2 weeks, while high-volume production runs can take 4–8 weeks. Some precision manufacturing company operations offer expedited services for urgent orders, reducing lead times by 30–50% for an additional fee.

Q7: How can I optimize my collaboration with a precision manufacturing company? A7: To optimize collaboration, provide clear and detailed specifications (drawings, 3D models), engage in design for manufacturability (DFM) reviews early, establish clear quality requirements, maintain open communication, and plan for a long-term partnership. This will help reduce costs, improve quality, and ensure on-time delivery.

Discuss Your Projects Needs with Yigu

At Yigu Technology, we are a trusted precision manufacturing company with over a decade of experience delivering high-quality, ultra-precise components and assemblies for clients across aerospace, medical, automotive, electronics, and construction industries. Our team of skilled engineers and technicians combines advanced technology with industry expertise to provide tailored solutions that meet your unique requirements—whether you need custom precision CNC machining, wire harness assembly, electro-mechanical integration, or specialized attachments like grapples and stump buckets.

Our comprehensive capabilities as a precision manufacturing company include: Advanced Precision Machining: 5-axis CNC milling, Swiss-style turning, wire EDM, and 3D printing for complex parts with tolerances as tight as ±0.0001 inches.End-to-End Assembly Services: Wire harness & cable assembly, electro-mechanical assembly, and kitting to streamline your production workflow.Custom Fabrication: Tailored solutions for heavy-duty attachments (grapples, rakes, stump buckets) and low-volume/high-volume custom parts.Rigorous Quality Control: Compliance with ISO 9001, AS9100, and ISO 13485 standards, supported by CMM inspection, SPC, and FDA-compliant processes for medical applications.Design for Manufacturability (DFM) Support: Collaborative engineering to optimize your part designs for cost, quality, and production efficiency.Supply Chain Resilience: Diversified raw material sourcing and ethical manufacturing practices to ensure consistent delivery and sustainability.

We understand that every project has unique challenges—whether it’s achieving ultra-tight tolerances, meeting regulatory requirements, scaling production, or adhering to strict lead times. As your partner precision manufacturing company, we prioritize open communication, transparency, and collaboration to deliver solutions that exceed your expectations. Our dedicated project managers will work closely with you from initial consultation to final delivery, providing regular updates and addressing any concerns promptly.

Contact us today to discuss your project needs. Let our expertise as a leading precision manufacturing company help you optimize your manufacturing workflow, reduce costs, and bring high-quality, precision products to market successfully.