Machined plastic parts offer unique advantages over metals, including lightweight construction, chemical resistance, electrical insulation, and design flexibility, making them ideal for demanding applications in medical, aerospace, and electronics industries.

When engineers need complex, high-precision components that are lightweight, corrosion-resistant, or electrically insulating, machined plastic parts often provide the optimal solution. Unlike injection molding which requires expensive tooling, CNC machining of plastics allows for rapid prototyping and production of low-to-medium volume parts with exceptional dimensional accuracy and surface quality. This guide explores the complete ecosystem of plastic machining – from selecting the right engineering-grade plastics like PEEK and Ultem to implementing critical design for manufacturability (DfM) principles that prevent warping and ensure cost-effectiveness. We'll compare plastics to traditional metals, examine advanced finishing options, and provide a framework for selecting a supplier who understands the nuanced requirements of machining polymers. Whether you're designing a surgical tool, a drone component, or a semiconductor fixture, this comprehensive resource will help you leverage the full potential of precision-machined plastics.

Introduction

The world of machined plastic parts represents a sophisticated intersection of material science and advanced manufacturing. While plastics are often perceived as inexpensive alternatives, the reality is that high-performance polymers like PEEK, PPS, and Ultem offer properties that metals cannot match – including inherent lubricity, radio transparency, and biocompatibility. Machining these materials requires specialized knowledge because plastics respond differently to cutting forces than metals; they have lower thermal conductivity, which can lead to heat buildup, and lower stiffness, which can cause deflection during machining. This article provides an engineering-focused deep dive into why and how to use machined plastics effectively. We'll move beyond basic material lists to explain the why behind material selection, the how of optimal machining processes, and the what to look for in a manufacturing partner to ensure your plastic components perform reliably in the field.

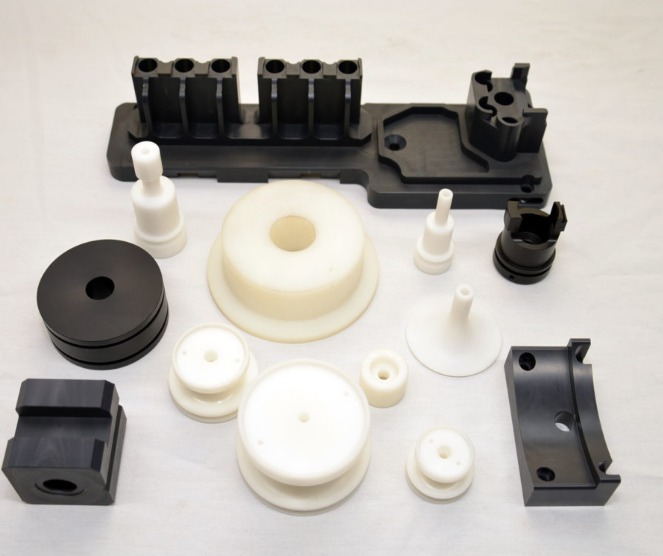

What Are Machined Plastic Parts?

Machined plastic parts are components created by subtractively removing material from a solid block, rod, or sheet of plastic using computer numerical control (CNC) equipment. This process contrasts with injection molding, where molten plastic is forced into a cavity. Machining is the preferred method when:

- Part volumes are low (prototypes, pilot runs, specialty equipment).

- Lead times must be short and mold tooling lead time is prohibitive.

- Tolerances are extremely tight (±0.001" / 0.025 mm or better), often exceeding typical molding capabilities.

- Material selection is critical, and the required high-performance polymer is not suitable for molding, or only available in stock shapes.

- Part geometry is simple enough that machining is more economical than investing in a mold.

The resulting parts are known for their dimensional precision, excellent surface finishes, and material integrity, as they are made from homogeneous, stress-relieved stock.

Which Plastics Are Best Suited for CNC Machining?

Not all plastics machine well. The ideal materials are engineering thermoplastics with good dimensional stability, rigidity, and resistance to heat generated during cutting.

| Material | Key Properties | Machinability & Key Considerations | Typical Applications |

|---|---|---|---|

| PEEK (Polyetheretherketone) | Exceptional chemical/thermal resistance (HDT 160°C), high strength, biocompatible. | Good. Requires sharp tools, high speeds, and good cooling to avoid melting. Can be brittle. | Aerospace bushings, medical implants, semiconductor wafers carriers, pump components. |

| Acetal (POM/Delrin®) | High stiffness, low friction, excellent dimensional stability, good creep resistance. | Excellent. Machines very cleanly with sharp edges. Prone to internal stresses; requires stable clamping. | Precision gears, bearing surfaces, fasteners, electrical insulators. |

| Nylon (PA 6, PA 66) | Good toughness, wear resistance, and bearing properties. | Fair/Good. Hygroscopic (absorbs moisture). Must be machined dry and from consistently dried stock to prevent dimensional change. | Wear pads, electrical connectors, rollers, bushings. |

| PTFE (Teflon®) | Ultimate chemical resistance, very low friction coefficient, excellent dielectric properties. | Difficult. Very soft and gummy; requires extremely sharp tools, high rake angles, and specialized techniques to achieve clean cuts. | Seals, gaskets, insulating spacers, chemical process parts. |

| Polycarbonate (PC) | High impact strength, optical clarity, good dimensional stability. | Fair. Prone to cracking if tools are not sharp. Can develop internal stresses. Requires careful fixturing. | Transurgical components, safety shields, lenses, housings. |

| Ultem (PEI) | High heat & flame resistance (UL94 V-0), good strength and stiffness. | Good. Also hygroscopic. Similar machining to PEEK but slightly less demanding. | Sterilizable medical devices, aerospace interior parts, high-temp electrical insulators. |

Expert Insight: A medical device company needed a small, complex connector for a surgical robot. The part required autoclavability (steam sterilization at 135°C), biocompatibility, and tolerances of ±0.0005" on critical bores. Injection molding ULTEM was risky due to the tight tolerances and low initial volume. Instead, they CNC machined the parts from ULTEM rod stock. This allowed them to validate the design, obtain FDA clearance, and begin limited clinical use with parts that met all requirements, deferring the mold investment until volumes justified it.

Key Machining Processes for Engineering Plastics

The optimal machining process depends on part geometry, plastic type, and required precision.

- CNC Milling: The most common process for creating complex 3D shapes, pockets, and contours in plastic blocks. High-speed spindles (20,000+ RPM) with sharp, highly polished carbide tools are essential to generate clean cuts without melting or gumming the plastic. Climb milling is often preferred to produce the best surface finish.

- CNC Turning: Used for creating round, axisymmetric parts like bushings, spacers, and knobs from plastic rod. Lathes equipped with high-pressure coolant directed at the cutting interface are crucial to dissipate heat, especially for materials like PEEK.

- CNC Drilling & Tapping: Creating holes in plastics requires specialized drill geometries (high helix angles) to efficiently evacuate chips and prevent heat buildup. Tapping can be challenging in brittle plastics; forming taps (which displace material rather than cut it) are often superior for ductile plastics like Acetal, producing stronger threads with no chip clearance issues.

How Do Machined Plastics Compare to Metal Components?

The choice between plastic and metal is often driven by functional requirements beyond mere strength.

| Parameter | Machined Plastics | Machined Metals (e.g., Aluminum, Steel) |

|---|---|---|

| Weight | Extremely low density (0.9-1.4 g/cm³ for most engineering plastics). | 3-9x heavier (Al: ~2.7 g/cm³, Steel: ~7.9 g/cm³). |

| Corrosion Resistance | Generally excellent, inert to a wide range of chemicals, solvents, and water. | Varies. Aluminum oxidizes; steel rusts. Stainless steel offers resistance but at higher cost and weight. |

| Electrical & Thermal Properties | Excellent electrical insulators. Generally low thermal conductivity (good for thermal break). | Conductive. Metals are electrical and thermal conductors. |

| Manufacturing Speed (Prototypes) | Fast. No tooling required. Complex parts can be machined directly from CAD files. | Fast for machining, but may require similar lead times. |

| Cost at Low Volumes | Typically lower. No tooling investment; cost is driven by material and machine time. | Comparable or higher for machining, but material cost per part may be lower for some metals. |

| Maximum Service Temperature | Lower. Ranges from ~80°C (Acetal) to 250°C+ (PEEK). Most are below 150°C. | Higher. Aluminum alloys can exceed 200°C; steels can operate at several hundred °C. |

Plastics excel in applications where weight reduction, chemical resistance, electrical insulation, or reduced part count (via complex, single-piece designs) are critical. For instance, a machined PEEK sleeve in a chemical pump replaces a multi-part assembly of metal, seals, and insulators, reducing weight, eliminating corrosion, and preventing galvanic coupling.

Critical Design Guidelines for Cost-Effective Production

Designing for machined plastic parts requires specific considerations to avoid high costs, poor quality, or part failure.

- Manage Internal Stress: Plastics are prone to stress relaxation and creep. Avoid designs with sustained high loads. Use generous fillets at all sharp corners to distribute stress.

- Account for Thermal Expansion: Plastics have a coefficient of thermal expansion (CTE) 5-10 times greater than metals. Design clearances for temperature swings and avoid press-fits with metal components unless carefully analyzed.

- Design Rigid Features: To counteract plastic's lower stiffness (modulus of elasticity), use ribs and gussets to reinforce thin walls and large flat surfaces, preventing flexure. Rib thickness should be 50-60% of the adjacent wall to avoid sink marks.

- Optimize for Sharp Tools: Features like sharp internal corners are impossible to machine (the tool has a radius). Design with a corner radius slightly larger than the intended tool's radius. Deep, small-diameter holes are difficult; follow a depth-to-diameter ratio of less than 10:1 whenever possible.

What Surface Finishing Options Are Available?

While machined plastics can have very fine as-machined finishes, specific applications require secondary finishing.

- Sanding & Polishing: Manual or automated processes to achieve optical clarity or a specific surface texture (Ra value). Successive finer grits are used, ending with a buffing compound.

- Vapor Polishing: A chemical process primarily for acrylic and polycarbonate. The part is exposed to solvent vapors that mildly melt the surface, creating a crystal-clear, glossy finish ideal for lenses and windows.

- Painting & Coating: Requires proper surface preparation. Plasma treatment is a highly effective, clean method to increase surface energy for adhesion. It can improve paint adhesion strength by over 50% compared to an untreated surface.

- Laser Marking/Engraving: For adding permanent, high-contrast logos, serial numbers, or calibration marks without inks or labels.

Tolerance Standards and In-Process Quality Control

Achieving tight tolerances in plastic is challenging due to material flexibility and thermal sensitivity.

- Realistic Tolerances: While ±0.001" (0.025 mm) is achievable on stable, thick-walled features of materials like Acetal, a more common and economical standard tolerance is ±0.005" (0.13 mm). Tolerances tighter than ±0.001" are possible but require exceptional process control.

- In-Process Quality: Key methods include:

- Thermal Management: Ensuring parts cool to a stable, consistent temperature before final finishing cuts and inspection.

- Fixturing Strategy: Using custom vacuum fixtures or low-pressure clamps to hold parts without distortion.

- Dimensional Verification: Using non-contact measurement like vision systems or laser scanners for delicate parts, and Coordinate Measuring Machines (CMM) with appropriate probe force settings for rigid parts.

Typical Applications Across Medical, Aerospace, and Electronics

The unique properties of machined plastics solve critical challenges in high-tech industries.

- Medical: Surgical instruments (handles, guides), implant trial components, imaging device parts (MRI-compatible), and single-use surgical tools. Materials: PEEK, Medical-Grade UHMW-PE, Polysulfone.

- Aerospace: Interior cabin components, low-weight brackets, electrical insulators, and non-magnetic sensor housings. Materials: ULTEM (for FST – flame, smoke, toxicity ratings), PEEK, PPS.

- Electronics & Semiconductors: Test sockets, wafer handling fixtures, insulating spacers, and RF components. Materials: PTFE for dielectric properties, PEEK for cleanliness and temperature resistance, Acetal for low-outgassing in vacuum.

What Should You Evaluate When Selecting a Supplier?

Not all machine shops are adept at plastics. Look for these specific capabilities:

- Material-Specific Experience: Ask for examples of parts they've machined from the specific polymer you intend to use (e.g., PEEK, Acetal).

- Dedicated Plastics Area: A shop that machines plastics in a separate area or with dedicated tools avoids contamination from metal chips (which can embed in softer plastics).

- Tooling & Process Knowledge: They should discuss tool geometry (high rake angles), speeds & feeds, and coolant strategies (often compressed air or mist, not flood coolant for many plastics).

- Quality Control Adaptations: Their quality plan should address thermal stabilization of parts before measurement and use appropriate, non-damaging inspection techniques.

Conclusion

Machined plastic parts are a powerful enabling technology, offering a unique combination of properties unavailable in metals. Success hinges on a deep understanding of polymer material science, application of specialized CNC machining techniques, and adherence to plastic-specific design rules. By partnering with a supplier who possesses genuine expertise in machining engineering thermoplastics, you can unlock innovative design solutions that reduce weight, eliminate corrosion, provide electrical insulation, and accelerate product development. From life-saving medical devices to cutting-edge aerospace components, precision-machined plastics continue to push the boundaries of what is possible in modern engineering.

Frequently Asked Questions (FAQ)

When should I choose machined plastic parts over injection molded parts?

Choose CNC machining for prototypes, low-volume production (typically less than 500-1000 parts), or when part tolerances are tighter than standard molding can achieve. Choose injection molding for high-volume production (thousands to millions) where the per-part cost becomes far lower after amortizing the mold tooling investment.

Can machined plastic parts hold threads as well as metal parts?

Yes, but design and process matter. In ductile plastics like Acetal and Nylon, thread-forming taps create strong, clean threads without chips. In brittle plastics like acrylic, thread cutting is used. For highest strength, threaded metal inserts (press-in, ultrasonic, or heat-staked) are recommended for plastics that will undergo repeated assembly/disassembly.

How does moisture affect the machining and performance of plastic parts?

Hygroscopic plastics (e.g., Nylon, ULTEM, ABS) absorb moisture from the air, which can cause them to swell. If machined from "wet" stock, the finished part will shrink as it dries, losing dimensional accuracy. A competent supplier will pre-dry these materials in a controlled oven before machining and store them properly. This is a critical step often overlooked by general machine shops.

Are machined plastic parts suitable for high-load structural applications?

They can be, with careful design. While no common plastic matches the absolute strength of steel, some like PEEK and fiber-reinforced composites have excellent strength-to-weight ratios. The key is to design for stiffness (using ribs and geometry) and to account for creep (plastic's tendency to slowly deform under constant load). For long-term, high-static loads, metals are generally more suitable.

Contact Yigu Technology for Custom Manufacturing.

At Yigu Technology, we possess deep, specialized expertise in the precision machining of engineering plastic parts. We understand that working with polymers like PEEK, ULTEM, and Acetal is a distinct discipline requiring specific tooling, processes, and environmental controls.

Our team of engineers will partner with you from the initial design phase, providing critical Design for Manufacturability (DfM) feedback tailored to plastics to ensure your part is optimized for performance, precision, and cost-effectiveness. We maintain a controlled environment for machining hygroscopic materials and utilize advanced, non-contact inspection methods to verify the quality of your delicate components.

If your project requires the unique advantages of high-performance machined plastics, partner with a supplier who truly understands the material. Contact Yigu Technology today to discuss your application and receive a comprehensive engineering analysis and quote.