Precision machined parts are defined by their ability to reliably perform under specific mechanical, thermal, and functional conditions, achieved through a combination of material science, advanced machining technologies, and rigorous metrology that ensures micron-level accuracy and consistency.

The term "precision" in manufacturing is often overused, but for components in aerospace, medical devices, and advanced optics, it carries a literal, measurable weight. A single micron of deviation can mean the difference between a successful satellite deployment and a catastrophic failure. True precision machined parts are the result of an engineered ecosystem where every variable—from the thermal stability of the machine tool to the measurement uncertainty of the quality lab—is controlled. This guide provides a detailed technical framework for understanding what differentiates standard parts from precision ones. We'll explore the specialized materials that maintain dimensional stability, the technologies that achieve sub-micron accuracy, the surface finish parameters critical for function, and the quality systems that guarantee zero-defect production. For engineers and procurement specialists sourcing mission-critical components, this knowledge is essential for specifying requirements and selecting capable manufacturing partners.

Introduction

In the realm of high-stakes manufacturing, precision machined parts are not merely components; they are functional elements where geometry, surface integrity, and material properties are inseparable from performance. Precision machining transcends standard CNC work, operating in tolerance bands where thermal expansion, tool deflection, and machine repeatability become the primary design constraints rather than the cutting tool itself. For example, a fuel injector nozzle for a jet engine must maintain orifice diameters within ±2 microns while withstanding extreme temperatures and pressures—a requirement impossible for conventional machining. This article deconstructs the multidisciplinary approach required to produce such parts. We will examine the material characteristics that enable stability, the machining processes that remove material at microscopic levels, and the metrology that validates each dimension. Our goal is to provide you with a comprehensive specification and evaluation framework, transforming how you approach the sourcing of components where failure is not an option.

What materials best suit precision machined parts?

Material selection is the foundational decision. The ideal material for precision work is not just strong or hard; it must exhibit exceptional dimensional stability, predictable machinability, and homogeneity.

| Material Category | Exemplary Alloys/Grades | Key Properties for Precision | Critical Machining Consideration |

|---|---|---|---|

| Stainless Steels | 304, 316, 17-4 PH, 440C | Good corrosion resistance, moderate thermal expansion, can be heat-treated for stability. | Work hardening: Can deform under tool pressure; requires sharp tools and positive rake angles to shear rather than push material. |

| Tool Steels | A2, D2, M2 | High hardness and wear resistance for tooling and gauges. | Post-machining heat treatment can cause distortion; often machined oversize, heat-treated, then finish-ground to final dimensions. |

| Aluminum Alloys | 6061-T6, 7075-T6, MIC-6® | Lightweight, good strength-to-weight, excellent machinability. | High thermal expansion coefficient (~24 µm/m·°C): Requires stringent temperature control during machining and inspection. |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | High strength-to-weight, biocompatible, low thermal conductivity. | Poor thermal conductivity leads to heat concentration at the cutting edge, requiring specialized coolants and tool coatings (AlTiN). |

| Engineering Plastics | PEEK, Acetal (Delrin®), Vespel® | Low density, electrical insulation, self-lubricating. | Low modulus of elasticity causes part flexure during machining; requires specialized, gentle fixturing and toolpaths. |

| Superalloys | Inconel 718, Hastelloy X | Retain strength at extreme temperatures (>600°C). | Extreme work hardening and high cutting forces; demand rigid setups and ceramic or CBN tooling. |

A relevant case involves a manufacturer of DNA sequencer components. They initially used standard 6061 aluminum but faced issues with dimensional drift over time. Switching to stress-relieved, cast aluminum tooling plate (like MIC-6®) eliminated the internal stresses that caused this drift. The premium material cost was offset by a 40% reduction in scrap and guaranteed long-term stability for optical alignment features.

Tolerances: how tight is tight enough?

Specifying tolerances is an exercise in functional necessity versus exponential cost. Understanding the standards is key.

- Commercial/Standard Machining: Tolerances typically range from ±0.005" (0.13 mm) to ±0.001" (0.025 mm). Suitable for non-critical housings and brackets.

- Precision Machining: This realm operates from ±0.001" (0.025 mm) down to ±0.0001" (0.0025 mm). Achieving this requires temperature-controlled environments (±1°C), high-end machine tools, and in-process metrology.

- Ultra-Precision/Micromachining: Tolerances within ±0.0001" (0.0025 mm) and below, often measured in sub-microns. This is the domain of optics, semiconductor, and medical implant manufacturing, requiring specialized machines often isolated from vibration and thermal flux.

The Cost of Precision: It's crucial to understand the relationship is not linear. Holding a ±0.0005" tolerance may cost 5-10 times more than holding a ±0.005" tolerance. The increase pays for slower cycle times, specialized tooling, advanced inspection (like CMM scanning), and a significantly higher scrap rate during process qualification. The guiding principle should be: specify the tightest tolerance only where it is critical to form, fit, or function.

Which machining technologies deliver micron-level accuracy?

Achieving micron-level results requires moving beyond standard CNC mills and lathes to technologies engineered for stability and feedback.

The Role of Machine Tool Design

- Construction: High-precision machines often use polymer concrete bases for superior vibration damping and thermal inertia compared to cast iron.

- Drive Systems: Linear motor drives eliminate the backlash and pitch error inherent in ball screws, providing smoother motion and more accurate positioning.

- Thermal Management: Machines incorporate cooling systems for spindles, ball screws, and even the machine structure to maintain thermal equilibrium, crucial for holding tolerances over long production runs.

Key Precision Machining Processes

- 5-Axis CNC Machining with On-Machine Probing: Allows complex geometries to be finished in a single setup (eliminating re-fixturing errors). Touch-trigger probes automatically measure the workpiece and adjust tool paths or offsets in real-time, creating a closed-loop system.

- Jig Grinding & ID/OD Grinding: For the hardest materials and tightest tolerances, grinding is the final operation. Jig grinders can achieve bores with roundness and size tolerances below 0.0001" (2.5 µm) and surface finishes below 8 µin Ra.

- Swiss-Type (Sliding Headstock) Turning: Ideal for long, slender, small-diameter parts. The guide bushing provides support millimeters from the cutting tool, minimizing deflection and allowing for extraordinary precision on features like medical bone screws or connector pins.

Surface finish requirements and measurement methods

Surface finish (Ra, Rz, Rmax) is a functional characteristic, not just cosmetic. It affects friction, wear, sealing, and fatigue life.

| Finish Parameter & Typical Range | Measurement Method | Functional Implication |

|---|---|---|

| Rough Machined (125-32 µin Ra) | Visual comparison to standards. | For non-contact, non-critical surfaces. |

| Standard Machined (32-16 µin Ra) | Portable surface roughness tester (stylus). | For general mechanical parts with sliding contact. |

| Fine Machined (16-4 µin Ra) | Benchtop profilometer. | For bearing surfaces, static seals, and improved fatigue resistance. |

| Precision Ground (8-2 µin Ra) | High-resolution profilometer or atomic force microscope (AFM). | For hydraulic seals, high-precision bearings, and optical mounts. |

| Lapped/Polished (2-0.1 µin Ra) | Optical interferometry or AFM. | For optical lenses, laser components, and semiconductor wafer chucks. |

For a high-pressure hydraulic valve spool, a surface finish of 8 µin Ra or better is specified. This fine finish minimizes friction and wear, ensuring consistent metering and preventing fluid leakage past the spool. The supplier would use a CNC turning center with ceramic tooling followed by a precision honing process, verifying the result with a contact profilometer that traces the surface and calculates the Ra value.

Quality-control tools for zero-defect production

Inspection at the end only finds defects; in-process control prevents them. A zero-defect philosophy is built on process validation and statistical monitoring.

- First Article Inspection (FAI) with 3D Scanning: Beyond checking listed dimensions, a blue light or laser 3D scanner captures the entire part geometry. This point cloud is compared to the original CAD model in software like PolyWorks, generating a full-color deviation map that validates the entire form, not just sampled dimensions.

- In-Process Gauging & SPC: Touch probes on the machine tool measure critical features after machining. This data feeds into Statistical Process Control (SPC) software. If a measurement trends toward a control limit, the process is stopped and adjusted before a single bad part is produced.

- Advanced Metrology for Validation: The final audit uses:

- Coordinate Measuring Machines (CMM): For geometric dimensioning and tolerancing (GD&T) analysis of flatness, perpendicularity, position, etc.

- Optical Comparators: For rapid 2D profile verification.

- Roundness/Form Testers: To measure cylindricity, concentricity, and runout at sub-micron levels.

How do industries apply these components in real life?

Precision parts are enablers of technological advancement across sectors.

- Aerospace: Turbine engine blades with complex internal cooling channels machined via 5-axis milling from a single nickel superalloy billet. Tolerances on airfoil profiles are held within ±0.0005" to ensure optimal aerodynamic efficiency and fuel burn.

- Medical: Orthopedic implants (knees, hips) machined from Ti-6Al-4V ELI or CoCr. The articulating surfaces are finished to a mirror polish (< 2 µin Ra) to minimize wear debris, while porous structures for bone ingrowth are created via additive manufacturing (3D printing) and then precision-machined to final fit.

- Semiconductor: Wafer chucks and electrostatic chucks (ESCs) that hold silicon wafers during lithography. They require extreme flatness (< 5 microns over 300mm), specific surface resistivity, and thousands of precisely machined microscopic holes for vacuum or cooling.

Supplier selection: what should buyers evaluate?

Choosing a precision machining partner requires a technical audit. Here are critical evaluation criteria beyond price:

- Technical Dialogue: Don't ask "Can you hold ±0.0005"? Ask, "How do you hold ±0.0005" on a thin-walled titanium feature?" Listen for answers discussing thermal control, tool pressure, and fixturing strategy.

- Investment in Metrology: A supplier's measurement capability defines their quality ceiling. Tour their quality lab (virtually or in person). Look for CMMs, optical comparators, roundness testers, and surface profilometers that are recently calibrated (with certificates).

- Process Documentation: Request a sample Process Control Plan or PFMEA (Process Failure Mode and Effects Analysis). This shows a proactive, systematic approach to preventing defects rather than a reactive one.

- Cultural Commitment: Look for certifications like AS9100 (aerospace) or ISO 13485 (medical). More importantly, assess their culture of continuous improvement (e.g., do they use Lean/Six Sigma? Do they invest in employee training?).

Conclusion

Specifying and sourcing precision machined parts is a deeply technical endeavor that bridges design intent with manufacturing reality. Success depends on a holistic understanding of how material properties dictate stability, how advanced machining technologies execute removal at microscopic scales, and how rigorous metrology validates every assumption. By applying the framework outlined here—from setting functionally-driven tolerances to conducting a thorough supplier technical audit—you position yourself not just as a buyer, but as an informed engineering partner. This partnership is essential for developing the components that push the boundaries of performance in the world's most advanced technologies. In precision machining, the right knowledge and the right partner are your most critical components.

Frequently Asked Questions (FAQ)

What is the difference between accuracy and repeatability in precision machining?

Accuracy is how close a measured value is to the true or intended value (hitting the bullseye). Repeatability is the ability to produce the same result under unchanged conditions (hitting the same spot, even if it's not the bullseye, over and over). For precision machined parts, high repeatability is often more critical than absolute accuracy, as consistent parts allow for predictable assembly and performance. A good process is both accurate and repeatable.

How does temperature control affect the precision of machined parts?

It is arguably the most critical factor. Most materials expand with heat. Aluminum, for example, expands approximately 2.4 µm per 100 mm per 1°C. A part machined at 22°C and measured at 24°C could be 5 µm out of tolerance on a 100mm feature without any machining error. High-precision shops maintain environmental control at ±1°C and allow parts to "soak" to room temperature before final operations and inspection.

Can you achieve the same precision with plastics as with metals?

It is possible but often more challenging. Plastics have a lower modulus of elasticity, meaning they deflect more under cutting forces, and a higher coefficient of thermal expansion. Achieving metal-like tolerances requires specialized techniques: very sharp tools, high spindle speeds, minimal clamping forces (often using vacuum fixtures), and meticulous control of the machining environment. Not all machine shops have this expertise.

What are the most common mistakes when designing parts for precision machining?

The top three are: 1) Specifying unnecessarily tight tolerances on non-critical features, which exponentially increases cost. 2) Ignoring the effects of internal stress in raw materials, which can cause post-machining distortion. 3) Designing features that cannot be measured as easily as they can be machined. Always consider: "How will the inspector verify this dimension?" If it requires a $50,000 specialty gauge, the design may need revision.

Contact Yigu Technology for Custom Manufacturing.

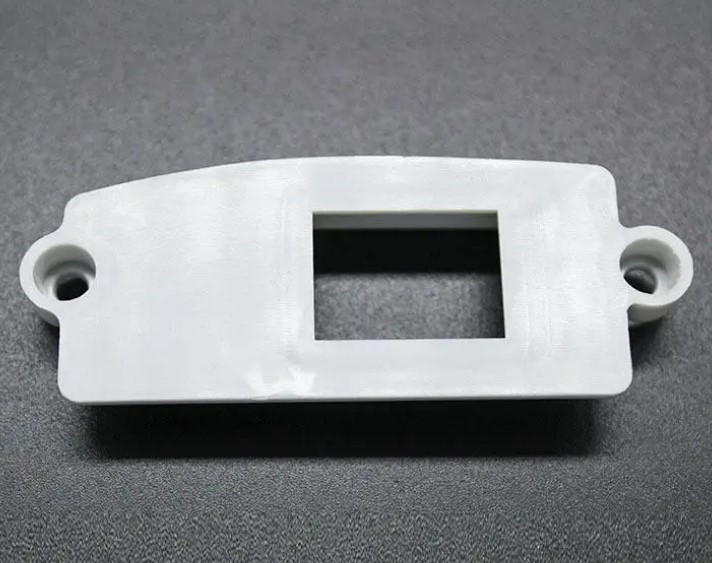

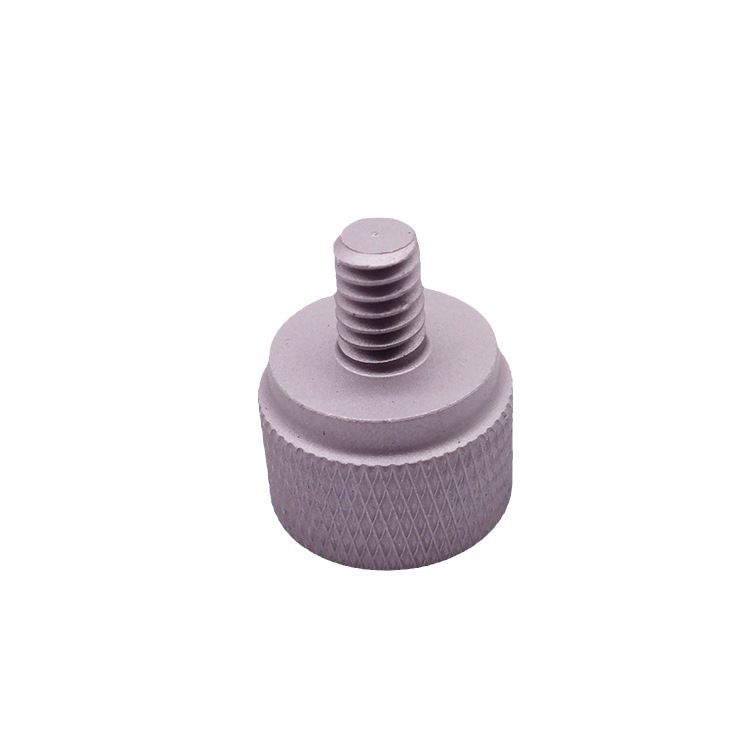

At Yigu Technology, precision is not a claim; it is a measurable output of our engineered systems. We specialize in manufacturing mission-critical precision machined parts for industries where failure is not an option—aerospace, medical, defense, and semiconductor.

Our capability is built on a foundation of advanced multi-axis CNC equipment housed in a temperature-controlled environment, a metrology lab equipped with high-precision CMMs and surface analysis tools, and a team of engineers who thrive on solving complex manufacturing challenges. We don't just follow prints; we partner with you from the Design for Manufacturability (DfM) phase to ensure your component is optimized for performance, reliability, and cost-effective production.

If your project demands components where every micron matters, partner with a manufacturer who has built their processes around that principle. Contact Yigu Technology to discuss your precision machining requirements.