What is Injection Blow Molding?

Injection blow molding is a specialized manufacturing process widely used in the plastics industry for producing high - quality, hollow plastic products with precise dimensions. It is a three - step process that combines the principles of injection molding and blow molding to create complex - shaped items such as bottles, containers, and various hollow components.

The Three - Step Process

- Injection Stage: In the first step, molten plastic is injected into a mold cavity, which is designed to form the pre - form or parison. This pre - form has the shape of the final product's neck and a tubular body. The injection molding process ensures high precision in the formation of the pre - form, especially in areas like the threaded neck of a bottle, where tight tolerances are crucial for proper sealing. For example, when producing a shampoo bottle, the pre - form will have the exact shape and threading of the bottle's neck.

- Transfer Stage: After the pre - form is cooled and solidified to a certain extent, it is transferred to a blow - molding mold. This transfer is usually done using a mechanical system that precisely positions the pre - form within the new mold. The transfer process needs to be carefully controlled to avoid any damage to the pre - form.

- Blow - Molding Stage: Once the pre - form is in the blow - molding mold, compressed air is injected into the pre - form. The air pressure causes the pre - form to expand and conform to the shape of the blow - molding mold cavity. This results in the creation of the final hollow product. The walls of the product are evenly distributed during this stage, ensuring consistent thickness and strength throughout the item.

Compared to other blow - molding processes like extrusion blow molding, injection blow molding offers several advantages. In extrusion blow molding, the pre - form is formed by extruding a continuous tube of molten plastic, which may lead to less precise control over the pre - form's dimensions, especially in the neck area. Injection blow molding, on the other hand, provides greater precision in the pre - form creation, making it ideal for products that require tight tolerances, such as pharmaceutical containers or high - end cosmetic bottles.

The Detailed Process of Injection Blow Molding

Step 1: Injection

- Raw Material Preparation: First, the appropriate plastic resin is selected based on the product's requirements. Common thermoplastic materials like polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are often used. These materials come in pellet form and are loaded into the hopper of the injection - molding machine. Before processing, the pellets may need to be dried to remove any moisture. For example, PET is highly hygroscopic, and if not properly dried, moisture can cause defects such as bubbles in the final product. The drying process typically occurs in a desiccant dryer at specific temperatures and for a set period, usually ranging from a few hours to overnight, depending on the material and its initial moisture content.

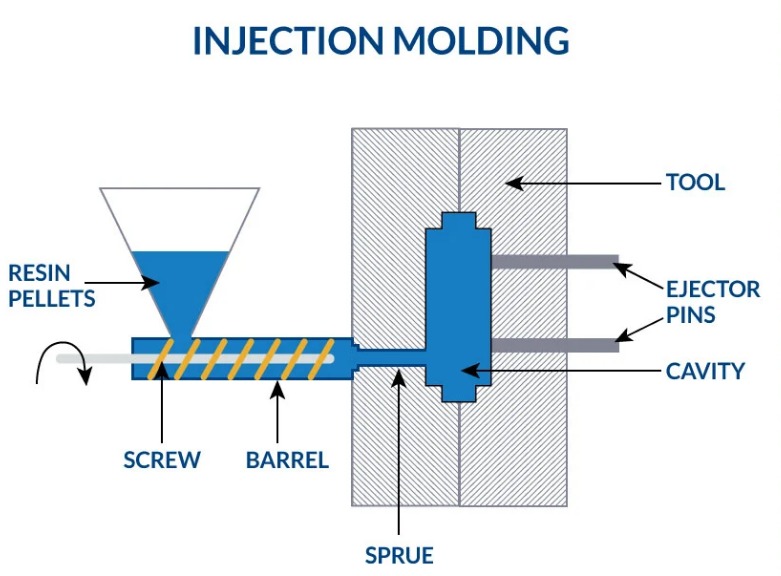

- Injection Molding Machine Operation: Inside the injection - molding machine, the plastic pellets are fed into a heated barrel. The barrel contains a screw that rotates to convey the pellets forward. As the pellets move along the screw, they are gradually heated by the barrel's external heaters. The temperature of the barrel is carefully controlled in different zones, with the rear (hopper end) being cooler (around 150 - 200°C for PE) and the front (nozzle end) being hotter (up to 250 - 300°C for some engineering plastics). The heat causes the plastic to melt and become a viscous, flowing material. Once the plastic is molten, the screw moves forward with high pressure (ranging from 50 - 200 MPa depending on the material and product complexity) to inject the molten plastic into a pre - form mold cavity. The mold cavity is designed to create the pre - form, which has the shape of the final product's neck and a short, tubular body. Precise control of the injection speed, pressure, and volume is crucial. For instance, a high - speed injection can lead to better filling of the mold but may also cause jetting, where the plastic shoots unevenly into the cavity.

Step 2: Transfer

- Transfer Process: After the pre - form is formed in the injection - mold cavity, it needs to be cooled slightly to gain enough strength to be moved without deforming. Once cooled, a mechanical transfer system, often consisting of robotic arms or precision - guided ejector mechanisms, carefully removes the pre - form from the injection mold. The pre - form is then transferred to the blow - molding mold. This transfer must be highly accurate, with positioning tolerances as small as ±0.1 mm in some cases. The transfer system aligns the pre - form precisely within the blow - molding mold so that the subsequent blow - molding process can be carried out smoothly.

- Precautions: During the transfer process, several precautions are necessary. Any vibration or sudden movement can damage the pre - form. For example, if the transfer arm accelerates or decelerates too quickly, it can cause the pre - form to bend or crack. Also, the temperature of the pre - form should be monitored. If it cools too much before transfer, it may become too brittle and break during handling. On the other hand, if it is still too hot, it can deform under its own weight or due to the forces applied during transfer.

Step 3: Blow Molding

- Blow - Molding Process: Once the pre - form is in the blow - molding mold, the mold closes tightly around it. Compressed air is then injected into the pre - form through a small opening, typically at the bottom of the pre - form. The air pressure, usually in the range of 2 - 10 bar, causes the pre - form to expand rapidly. As it expands, the softened plastic conforms to the shape of the blow - molding mold cavity, which is the final shape of the product, such as a bottle or container. The walls of the pre - form are evenly distributed during this expansion, resulting in a product with consistent wall thickness. For example, a well - made plastic bottle will have a wall thickness variation of less than ±0.1 mm around its circumference.

- Cooling and Finishing: After the plastic has expanded to fill the mold cavity, it is cooled to solidify the shape. The cooling is often achieved by circulating cool water or air through channels in the mold. The cooling time depends on the size and material of the product, but it generally ranges from a few seconds to a minute. Once cooled, the mold opens, and the finished product is ejected. Minor finishing operations may be required, such as trimming any excess plastic or flash that may have formed during the process.

Injection Blow Molding vs Other Molding Methods

Comparison with Extrusion Blow Molding

Injection blow molding and extrusion blow molding are two common techniques in the plastics manufacturing industry, each with its own characteristics. Here is a comparison between them in terms of several key aspects:

| Aspect | Injection Blow Molding | Extrusion Blow Molding |

| Cost - Initial Investment | Higher due to more complex machinery and molds. For example, a high - precision injection blow - molding machine can cost \(200,000 - \)500,000, and the molds are also expensive to fabricate, with a set of molds for a small - scale production run potentially costing \(50,000 - \)100,000. | Lower initial investment. An extrusion blow - molding machine can be in the range of \(100,000 - \)300,000, and the molds are generally less costly, perhaps \(20,000 - \)50,000 for a basic set. |

| Cost - Unit Production | Lower unit cost for high - volume production as it has high production efficiency and less material waste. Once the production volume reaches 100,000 units or more, the cost per unit can be relatively low. | Higher unit cost for small - to - medium production volumes due to more material waste during the continuous extrusion process. For production runs of less than 50,000 units, the cost per unit may be higher compared to injection blow molding in some cases. |

| Product Characteristics - Precision | High precision, especially in the neck area of products like bottles. Tolerances can be maintained within ±0.05 mm in critical areas. This makes it suitable for products that require tight - fitting caps or closures, such as pharmaceutical bottles. | Lower precision compared to injection blow molding. Tolerances are typically in the range of ±0.2 mm, which may not be suitable for products with strict sealing requirements. |

| Product Characteristics - Wall Thickness Uniformity | Excellent wall thickness uniformity. The pre - form creation in injection molding allows for better control over the material distribution, resulting in a wall thickness variation of less than ±0.1 mm around the product's circumference. | Wall thickness uniformity is relatively lower. There can be more significant variations, up to ±0.3 mm in some cases, due to the nature of the continuous extrusion process. |

| Product Size Limitation | Limited to relatively smaller - to - medium - sized products, typically with a maximum volume of around 2 - 3 liters for most common applications. Larger products may face challenges in terms of the transfer and blow - molding processes. | Can produce larger products, with some machines capable of manufacturing products up to 100 liters or more. It is more suitable for large - scale containers like industrial drums. |

Application Cases of Injection Blow Molding

In the Packaging Industry

Injection blow molding has found extensive applications in the packaging industry.

- Pharmaceutical Packaging: It is widely used for producing pharmaceutical bottles. These bottles require high precision in their neck and cap areas to ensure proper sealing and prevent contamination of the drugs inside. For example, small - volume vials for liquid medications often use injection blow - molded containers. The tight tolerances achieved through this process ensure that the bottles can be securely sealed with stoppers or caps, maintaining the integrity of the pharmaceutical products during storage and transportation. A study by the pharmaceutical packaging research institute shows that over 70% of high - end pharmaceutical bottles are produced by injection blow molding due to its ability to meet strict quality and safety standards.

- Beverage Packaging: Many beverage companies use injection blow - molded PET bottles. These bottles need to have a consistent wall thickness to withstand the pressure of carbonated beverages. For instance, the 500 - ml and 1 - liter soda bottles that are commonly seen in the market are often made through injection blow molding. The process allows for the creation of bottles with smooth surfaces and precise shapes, which are not only aesthetically pleasing but also suitable for high - speed filling operations on production lines. According to market statistics, in the global beverage packaging market, about 40% of plastic bottles are produced by injection blow molding, and this proportion is increasing year by year.

In the Automotive Industry

In the automotive sector, injection blow molding is used for manufacturing various components.

- Interior Components: Components like air ducts are often made using injection blow molding. Air ducts need to have a smooth inner surface to ensure efficient air flow within the vehicle's heating, ventilation, and air - conditioning (HVAC) systems. The process enables the production of ducts with complex shapes and precise dimensions. For example, in luxury cars, the air ducts are designed to be not only functional but also lightweight to improve fuel efficiency. Injection blow - molded air ducts can meet these requirements by using lightweight plastic materials such as polypropylene (PP).

- Exterior Components: Some exterior components, such as small - sized trim parts or decorative elements, are also produced through injection blow molding. These parts need to have good weather resistance and dimensional stability. For instance, certain plastic trims around the headlights or taillights are injection blow - molded. The process can create parts with a high - quality surface finish, which is important for the overall appearance of the vehicle.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values injection blow molding. This process offers distinct advantages in custom product manufacturing. The high precision it provides is crucial for custom - made items, especially those with complex shapes or tight - tolerance requirements. For example, when creating custom - designed containers for specific chemicals, the precise control over dimensions ensures proper sealing and compatibility.

However, challenges also exist. The high initial investment in equipment and molds can be a barrier, especially for small - scale custom orders. Additionally, the complexity of the three - step process requires skilled operators to ensure consistent quality. Yigu Technology addresses these challenges by leveraging its expertise in custom manufacturing, optimizing production processes, and continuously researching new materials and techniques to make injection blow molding more efficient and cost - effective for its customers.

FAQ

What types of plastics are most suitable for injection blow molding?

Plastics with good melt - flow properties and high melt - strength are ideal for injection blow molding. Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are commonly used. For example, PET is widely used in beverage bottle production due to its excellent clarity, strength, and gas - barrier properties. PE and PP are popular for their low cost, good chemical resistance, and ease of processing. These plastics can be easily melted, injected to form pre - forms, and then blow - molded into the final products while maintaining the desired shape and quality.

How can I reduce the cost of injection blow molding?

- Optimize Production Volume: Increase the production volume as much as possible. Since the initial investment in equipment and molds is high, high - volume production can spread these costs over more units, reducing the unit cost. For example, if the mold cost is \(50,000, producing 10,000 units will result in a mold - cost - per - unit of \)5, while producing 100,000 units will bring it down to $0.5 per unit.

- Material Selection: Choose cost - effective raw materials without sacrificing product quality. Sometimes, substituting a more expensive engineering plastic with a suitable commodity plastic can significantly cut material costs. Also, consider recycled plastics if they meet the product's quality requirements.

- Efficient Process Design: Minimize waste by optimizing the pre - form design and the blow - molding process. For instance, proper control of the blow - molding air pressure can ensure uniform wall thickness, reducing the need for rework due to thickness variations.