What is Gas Assisted Injection Molding?

Gas Assisted Injection Molding (GAIM), as an innovative technology in the plastic processing field, has been increasingly adopted by manufacturers to produce high - quality plastic products. In simple terms, GAIM is a process of injecting inert gas, usually nitrogen, into the plastic melt to form a hollow structure within the final product.

The process of Gas Assisted Injection Molding can be divided into several key steps. First, a precisely measured amount of molten plastic is injected into the mold cavity. This initial injection is often a “short - shot,” which means that less plastic is injected than is required to completely fill the mold. Then, through a specialized gas - injection system, high - pressure nitrogen gas is introduced into the mold cavity filled with the molten plastic. The gas diffuses within the molten plastic, creating a hollow channel inside the plastic part. This is because the gas will preferentially flow into the areas with higher temperature and lower viscosity of the plastic melt. The outer layer of the plastic, which has a lower temperature and higher viscosity, solidifies to form the outer wall of the product, ensuring the surface integrity of the plastic part.

For example, when manufacturing a large - scale plastic component like an automotive interior panel, traditional injection molding might face issues such as long cooling times and high material usage. With GAIM, a hollow structure can be created inside the panel. The gas is injected after a partial filling of the plastic melt. The gas then expands, pushing the plastic to the outer walls of the mold, forming a strong yet lightweight panel. This not only reduces the weight of the part but also significantly shortens the cooling time.

The Working Principle in Detail

Step - by - Step Process

- Initial Plastic Injection (Short - shot):

- First, the plastic resin is heated to its melting point in the injection unit of the molding machine. For example, if we are using polypropylene (PP), it needs to be heated to around 180 - 250°C depending on the grade.

- A measured amount of the molten plastic is then injected into the mold cavity. This amount is less than what is required to completely fill the mold, which is known as a “short - shot.” The short - shot volume is carefully calculated based on the design of the final product. For a plastic chair leg produced by gas - assisted injection molding, the short - shot might be around 60 - 70% of the total volume of the chair leg mold cavity. This initial injection creates a preliminary shape within the mold, and the plastic starts to cool and form a solid - like outer skin near the cooler mold walls.

- Gas Injection:

- After the short - shot of plastic is in place, high - pressure nitrogen gas, typically at pressures ranging from 10 - 30 MPa, is introduced into the mold cavity through a gas - injection nozzle. The gas injection nozzle can be located at different positions in the mold, such as at the gate or at specific points along the runner system. For a complex - shaped automotive interior component, multiple gas - injection nozzles might be used to ensure even gas distribution.

- The gas injection timing is crucial. It should start shortly after the plastic injection to prevent the plastic from solidifying too much before the gas can penetrate. A well - timed gas injection can ensure that the gas effectively creates the desired hollow structure.

- Gas Diffusion and Hollow Structure Formation:

- Once the gas is injected, it begins to diffuse within the molten plastic. Since gas always seeks the path of least resistance, it moves towards the areas where the plastic has a higher temperature and lower viscosity.

- As the gas diffuses, it pushes the molten plastic towards the walls of the mold cavity. This results in the formation of a hollow channel in the center of the plastic part. The outer layer of the plastic, which has cooled slightly and has a higher viscosity, remains in place to form the outer surface of the product, maintaining its integrity and dimensional accuracy. For a large - diameter plastic pipe made by gas - assisted injection molding, the gas creates a hollow core, reducing the weight of the pipe while still maintaining its structural strength.

- Cooling and Ejection:

- After the hollow structure is formed, the mold is cooled to solidify the plastic completely. Cooling channels in the mold are used to circulate a coolant, usually water, to speed up the cooling process. The cooling time is significantly shorter compared to traditional injection molding for thick - walled parts because the gas - created hollow structure reduces the amount of plastic that needs to be cooled.

- Once the plastic is fully solidified, the mold opens, and the finished part is ejected using ejector pins or other ejection mechanisms.

How Gas Moves in the Melt

Gas movement in the molten plastic is mainly determined by the viscosity and temperature distribution of the plastic melt. Plastic viscosity is a measure of its resistance to flow, and it is highly dependent on temperature. As the temperature of the plastic increases, its viscosity decreases, making it easier for the gas to flow through.

In the initial stage of gas injection, the gas will first enter the regions of the plastic melt that are closest to the gas - injection point and have the highest temperature. These regions have lower viscosity, allowing the gas to penetrate more easily. For instance, in a plastic part with a non - uniform thickness, the gas will preferentially flow towards the thicker sections because they cool down more slowly and thus have a higher temperature and lower viscosity compared to the thinner sections.

As the gas continues to move, it gradually forms a continuous channel within the plastic. The pressure of the gas also plays a role in its movement. Higher gas pressures can force the gas to move into areas with relatively higher viscosity, but this also needs to be carefully controlled to avoid over - penetration or causing defects in the plastic part. The goal is to create a smooth, hollow structure that is evenly distributed within the plastic part, ensuring the final product has the desired strength and appearance.

Applications in Different Industries

Gas Assisted Injection Molding has found wide - spread applications across various industries due to its unique advantages. Here are some examples of how it is used in different sectors:

Automotive Industry

- Automotive Interiors: In the production of car dashboards, GAIM plays a crucial role. Traditional injection molding would result in a heavy and costly dashboard. With GAIM, a hollow structure can be created inside the dashboard. For example, the central part of the dashboard, which is not visible and does not need to have a solid structure for functionality, can be made hollow by injecting nitrogen gas after a partial plastic injection. This reduces the weight of the dashboard by up to 30 - 40%, according to industry data. It also helps in reducing the internal stress of the part, which is important as dashboards are often exposed to temperature variations during the use of the vehicle. This stress - reduction feature minimizes the risk of cracking or warping over time.

- Automotive Exteriors: Bumpers are another area where GAIM is applied. A bumper needs to be strong enough to withstand minor collisions while also being lightweight to improve fuel efficiency. Gas - assisted injection molding allows for the creation of a bumper with a thick outer layer for impact resistance and a hollow interior for weight reduction. Some car manufacturers have reported that by using GAIM for bumper production, they can achieve a weight reduction of 20 - 30% compared to traditional molding methods, while maintaining the required strength and impact - absorbing capabilities.

- Engine Components: Certain engine components, such as intake manifolds, can be produced using GAIM. The complex shapes of intake manifolds require a high - precision molding process. GAIM enables the production of manifolds with smooth internal channels. The gas injection helps in creating a uniform wall thickness, which is important for the efficient flow of air - fuel mixtures in the engine. This can lead to improved engine performance, with some studies showing a 5 - 10% increase in fuel efficiency due to the optimized design of intake manifolds produced by GAIM.

Electronics Industry

- Product Enclosures: In the production of laptop and tablet cases, GAIM is increasingly being used. These devices require enclosures that are both lightweight and strong to protect the internal components. For instance, a laptop case made by GAIM can have a hollow - structured frame. The outer shell is made of a thin but durable layer of plastic, while the internal structure has hollow sections created by gas injection. This not only reduces the weight of the case by about 15 - 20% but also provides sufficient strength to withstand normal handling and minor impacts.

- Internal Structure Parts: Components like heat sinks inside electronic devices can also benefit from GAIM. Heat sinks need to have a large surface area for effective heat dissipation while being lightweight to avoid adding excessive weight to the device. GAIM allows for the creation of heat sinks with complex internal structures, such as hollow fins. These hollow fins increase the surface area for heat transfer while reducing the overall weight of the heat sink. This can lead to better heat management in electronic devices, improving their performance and lifespan.

Medical Industry

- Medical Device Enclosures: Devices such as patient monitors and diagnostic equipment often have enclosures produced by GAIM. These enclosures need to meet high - precision and hygienic standards. GAIM can produce enclosures with smooth surfaces and precise dimensions. The use of inert gas (usually nitrogen) in the process also ensures that there are no harmful by - products or contaminants introduced during the molding process. For example, a patient monitor enclosure made by GAIM can have a seamless finish, which is easy to clean and disinfect, reducing the risk of cross - contamination in a medical environment.

- Medical Instrument Components: Components of surgical instruments, like handles, can be manufactured using GAIM. The handles need to have a good grip and be lightweight for the comfort of the surgeon during long - term use. GAIM can create handles with a hollow core, reducing their weight without sacrificing strength. The smooth surface finish obtained through GAIM also meets the strict cleanliness requirements of the medical industry, as any rough surfaces could harbor bacteria.

Yigu Technology's Perspective

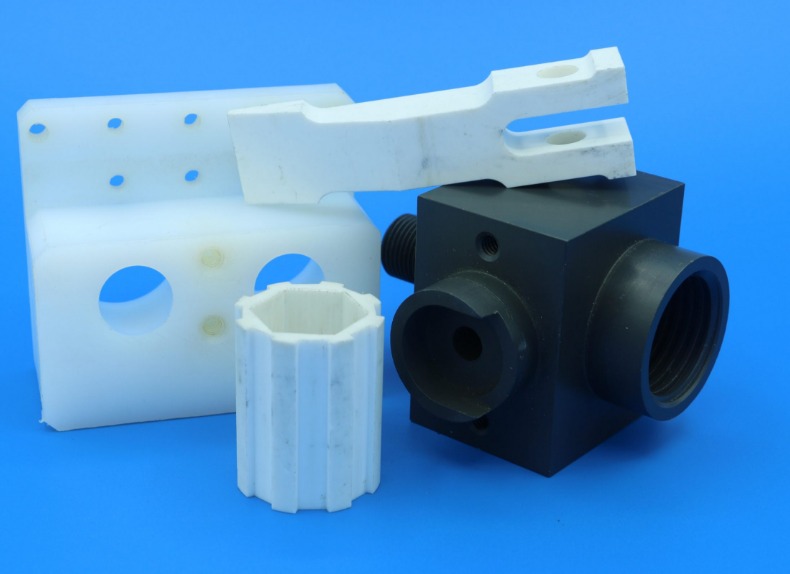

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values Gas Assisted Injection Molding (GAIM). This technology offers remarkable design flexibility, enabling the integration of complex plastic components into a single unit. It allows for the combination of thick - walled and thin - walled sections within one part, which is a significant advantage in product design.

From a cost - perspective, GAIM is also appealing. With reduced material usage due to the formation of hollow structures, the overall cost of production is cut down. The shortened cooling times and cycle times also lead to lower energy consumption. Additionally, the lower injection pressure requirements mean that smaller - tonnage injection machines can be used, further reducing equipment investment and maintenance costs.

In terms of product quality, GAIM significantly improves the strength - to - weight ratio of products. The hollow “reinforcement” design not only enhances the part's strength but also minimizes micro - shrinkage, reducing the risk of warping and deformation. The process also effectively eliminates sink marks, improving the surface quality of the final products.

Yigu Technology has harnessed the power of GAIM to provide high - quality products to its clients. By leveraging this technology, we can meet the diverse needs of different industries, whether it's the automotive, electronics, or medical sectors. Our team of experts is dedicated to optimizing the GAIM process for each specific product, ensuring the best possible results in terms of quality, cost - effectiveness, and production efficiency.

FAQs about Gas Assisted Injection Molding

What are the main advantages of Gas Assisted Injection Molding?

- Design Flexibility: GAIM allows for the creation of complex shapes with variable wall thicknesses. For example, parts with thick - walled sections for strength and thin - walled sections for aesthetics can be produced in a single molding process.

- Cost - effectiveness: Reduces material usage due to the hollow structure formed by gas injection, which can lead to cost savings of up to 20 - 40% in material costs for some products. Shorter cooling times also result in lower energy consumption and higher production efficiency.

- Improved Product Quality: Minimizes internal stress and sink marks, resulting in products with better dimensional stability and surface finish. The hollow “reinforcement” structure can also enhance the strength - to - weight ratio of the product.