Introduction

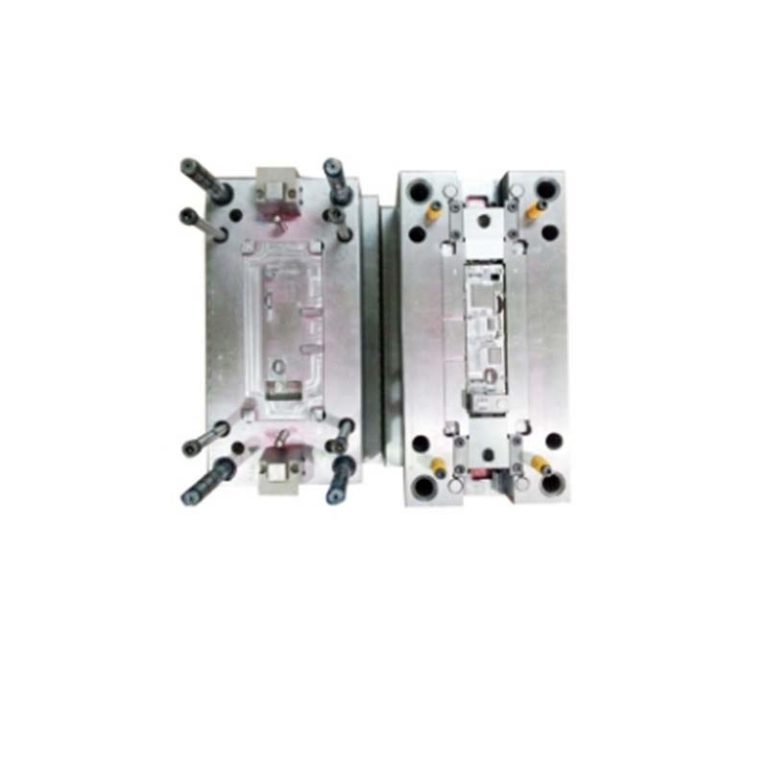

Understanding Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process for producing plastic parts in high volumes. It involves melting plastic pellets, injecting the molten plastic into a mold cavity under high pressure, allowing it to cool and solidify, and then ejecting the finished part. This process is highly efficient and can create complex shapes with high precision. The applications of plastic injection molding span across various industries. In the consumer electronics field, components like phone cases, computer housings, and keyboards are often made through this process. The automotive industry uses it to manufacture parts such as dashboard components, door panels, and bumpers. Even in the medical sector, items like syringes, medical device housings, and prosthetics components benefit from plastic injection molding.

Despite its many advantages, plastic injection molding is not without its challenges. During the process, several common defects can occur, which not only affect the quality of the final product but also lead to increased production costs and waste. In the following sections, we will delve into these common defects and explore effective ways to avoid them, equipping you with the knowledge to optimize your plastic injection molding processes.

Common Defects in Plastic Injection Molding

Short Shots

Short shots occur when the molten plastic fails to completely fill the mold cavity. The part appears incomplete, with some areas not being formed as intended. This defect is often caused by several factors. Firstly, improper mold design can be a culprit. If the runner system is too long or has a small cross - sectional area, it can create high flow resistance, preventing the plastic from reaching all parts of the cavity. For example, in a complex - shaped mold with long and narrow runners, the plastic may cool down and solidify before fully filling the cavity.

Secondly, insufficient injection pressure is a common cause. If the pressure applied during injection is not high enough to overcome the flow resistance in the mold, short shots will occur. According to industry data, in about 30% of short - shot cases, insufficient injection pressure is the main factor. Additionally, low plastic melt temperature or high mold temperature can lead to reduced plastic fluidity, making it difficult for the plastic to flow smoothly into the mold cavity.

Flash

Flash, also known as burrs or overflow, appears as thin, excess plastic that forms around the edges of the molded part, usually at the mold parting lines, slider joints, or around ejector pins. One of the primary causes is an improper mold closure. If the mold halves do not fit tightly together, there will be gaps through which the molten plastic can escape. This could be due to worn - out mold components, misaligned mold plates, or insufficient clamping force. For instance, if the clamping force of the injection molding machine is set too low, it cannot hold the mold halves firmly during injection, resulting in flash.

High injection pressure can also force the plastic to flow into the gaps between the mold components, creating flash. Research shows that when the injection pressure exceeds the mold's clamping force by more than 10%, the likelihood of flash occurrence increases significantly. Moreover, a high plastic temperature can increase its fluidity, making it more likely to flow into small gaps and form flash.

Warpage

Warpage refers to the distortion of the molded part from its intended shape. This defect can have a significant impact on the part's dimensional accuracy and appearance, making it difficult to assemble with other components. Uneven cooling is a major cause of warpage. When different areas of the part cool at different rates, internal stresses are generated, causing the part to warp. For example, if one side of a plastic part cools much faster than the other due to uneven cooling channels in the mold, the part will tend to bend towards the cooler side.

The design of the product structure also plays a crucial role. Parts with non - uniform wall thickness are more prone to warpage. When a part has thick and thin sections, the thicker areas cool more slowly, resulting in differential shrinkage and causing the part to warp. In fact, products with a wall - thickness variation of more than 20% are at a high risk of warping.

Sink Marks

Sink marks are small depressions or indentations that appear on the surface of the molded part, usually in areas of thick walls or near ribs and bosses. They are mainly caused by insufficient material to compensate for the shrinkage that occurs during cooling. When the plastic cools and solidifies, it shrinks. If there is not enough plastic supplied during the cooling process, sink marks will form. Wall - thickness variations are a common cause. In parts with thick sections, the plastic in these areas cools more slowly and shrinks more, while the thinner sections solidify faster. This differential shrinkage leads to sink marks.

Insufficient packing pressure is another factor. During the packing phase, the pressure applied to the molten plastic is not enough to fill the cavity and compensate for the shrinkage, resulting in sink marks. According to industry experience, about 40% of sink - mark problems can be attributed to insufficient packing pressure.

Silver Streaks

Silver streaks are thin, silver - colored lines that appear on the surface of the molded part, which can significantly affect the part's appearance quality. High moisture content in the raw materials is a common cause. When the plastic pellets contain excessive moisture, during the melting process, the water vaporizes and forms small bubbles in the molten plastic. As the plastic flows into the mold, these bubbles burst, leaving behind silver - colored streaks. For example, if the moisture content of nylon pellets exceeds 0.2%, silver streaks are very likely to occur.

Plastic degradation due to overheating can also cause silver streaks. When the plastic is exposed to high temperatures for too long in the barrel of the injection molding machine, it decomposes, producing gas that results in silver - colored marks on the part surface. Additionally, poor mold venting can trap air or gas in the mold cavity, which is then pushed into the plastic, creating silver streaks.

How to Avoid These Defects

Precise Mold Design

A well - designed mold is the foundation for preventing defects in plastic injection molding. The runner system, which channels the molten plastic from the injection unit to the mold cavity, should be designed with careful consideration. The length of the runner should be minimized to reduce flow resistance. For example, in a large - scale production of plastic toys, if the runner is too long, the plastic may cool down significantly before reaching the end of the cavity, increasing the risk of short shots. A proper cross - sectional area of the runner is also crucial. A narrow runner can cause excessive pressure drop, while a too - wide runner may lead to material waste and longer cooling times.

The location and size of the gate, where the plastic enters the mold cavity, play a vital role. An inappropriate gate location can result in uneven filling of the cavity, leading to issues like short shots, weld lines, and warpage. For complex - shaped parts, multiple gates may be required to ensure uniform filling. The gate size should be optimized according to the part's size, shape, and the type of plastic used. A gate that is too small can cause high shear stress on the plastic, leading to degradation and surface defects, while a too - large gate may cause problems during the ejection of the part.

The structural strength of the mold is another important aspect. A mold with insufficient strength may deform under the high pressure during injection, causing flash and affecting the dimensional accuracy of the part. Mold plates should be thick enough, and support structures such as ribs and pillars should be properly placed to enhance the mold's rigidity.

Optimal Process Parameters

Optimizing process parameters is essential for minimizing defects. Injection pressure needs to be carefully adjusted. It should be high enough to ensure that the molten plastic fills the entire mold cavity but not too high to avoid flash or damage to the mold. For small, thin - walled parts, a relatively lower injection pressure may be sufficient, while large, thick - walled parts may require higher pressure. Industry data shows that for most common plastic materials, the injection pressure typically ranges from 50 - 200 MPa, but this can vary greatly depending on the specific application.

Injection speed also impacts the quality of the molded part. A too - fast injection speed can cause air to be trapped in the cavity, leading to the formation of voids, silver streaks, or burn marks. On the other hand, a too - slow injection speed may result in short shots or poor surface finish. For example, when molding a precision - engineered electronic component, a controlled injection speed is crucial to ensure a smooth surface and accurate dimensions.

Plastic temperature affects its viscosity and fluidity. If the plastic is not heated to the appropriate temperature, it may not flow properly, causing short shots or uneven filling. Different plastic materials have different recommended melting temperature ranges. For instance, the melting temperature of polyethylene (PE) is around 120 - 200°C, while that of polycarbonate (PC) is approximately 270 - 320°C.

Mold temperature has a significant influence on the cooling rate of the plastic. An uneven mold temperature can lead to warpage and sink marks. Cooling channels in the mold should be designed to ensure uniform cooling. The mold temperature should be maintained within a specific range according to the plastic material. For example, for ABS plastic, the mold temperature is often kept between 40 - 80°C.

The packing pressure and time are important for compensating the shrinkage of the plastic during cooling. Sufficient packing pressure and an appropriate packing time can help reduce sink marks. Generally, the packing pressure is about 60 - 90% of the injection pressure, and the packing time ranges from a few seconds to tens of seconds, depending on the part's size and thickness.

Cooling time is also critical. If the part is ejected from the mold before it has cooled and solidified sufficiently, it may deform. The cooling time should be long enough to ensure that the part has reached a stable shape and size. However, an overly long cooling time will reduce production efficiency. Calculating the cooling time based on the part's thickness, plastic material, and mold temperature can help optimize the process.

High - Quality Raw Materials

The quality of the raw materials directly affects the quality of the final product. Selecting the right plastic granules is the first step. Different plastic materials have different properties, such as strength, heat resistance, chemical resistance, and flowability. For example, if you are manufacturing parts for use in a high - temperature environment, you should choose a heat - resistant plastic like polyetheretherketone (PEEK). If the part requires high impact resistance, materials like acrylonitrile - butadiene - styrene (ABS) or polycarbonate (PC) may be more suitable.

Additives can also play an important role in improving the performance of the plastic. For example, antioxidants can prevent the plastic from degrading due to oxidation during the injection molding process. Lubricants can improve the flowability of the plastic, reducing the risk of short shots and improving the surface finish. However, the type and amount of additives should be carefully controlled to avoid adverse effects on the plastic's properties.

Proper drying of the plastic pellets is crucial, especially for hygroscopic plastics like nylon. Moisture in the plastic can cause silver streaks, bubbles, and reduced mechanical properties. The plastic should be dried to the recommended moisture content before being used in the injection molding process. For example, nylon pellets are typically dried at around 80 - 100°C for several hours to reduce the moisture content to an acceptable level.

Regular Equipment Maintenance

Regular maintenance of the injection molding machine and the mold is necessary to ensure consistent production quality. The screw in the injection unit should be checked regularly for wear and tear. A worn - out screw may not be able to convey the plastic evenly or generate the required pressure, leading to issues like inconsistent shot size and poor plasticization. The barrel, where the plastic is melted, should also be inspected for signs of damage or corrosion. Any irregularities in the barrel's inner surface can affect the plastic's flow and melting characteristics.

Heating elements such as heating coils should be maintained to ensure they are functioning properly. Uneven heating can cause the plastic to have inconsistent temperatures, leading to defects. The nozzle, through which the molten plastic is injected into the mold, should be kept clean and free from blockages. A blocked nozzle can prevent the plastic from flowing smoothly, resulting in short shots or high - pressure build - up.

Mold maintenance is equally important. The mold should be cleaned regularly to remove any residue or contaminants that may affect the part's surface finish or cause sticking. The moving parts of the mold, such as slides and ejector pins, should be lubricated to ensure smooth operation. Regular inspection for signs of wear, such as scratches or dents on the mold cavity surface, is also necessary. Any damage to the mold cavity can be transferred to the molded part, resulting in defects.

Yigu Technology's Perspective

At Yigu Technology, as a non - standard plastic metal products custom Supplier, we deeply understand the importance of avoiding defects in plastic injection molding. We always attach great importance to communication with customers before production. By thoroughly understanding their product requirements, we can provide professional suggestions on mold design and material selection, laying a solid foundation for high - quality production.

Our professional team strictly controls every production link. From precise mold design and optimization of process parameters to the selection and management of high - quality raw materials, we ensure that each step meets the highest standards. Regular equipment maintenance is also a top priority for us, which helps to prevent equipment - related defects and ensures stable production. With years of experience and a customer - oriented attitude, we are committed to providing customers with excellent plastic injection molding solutions, minimizing defects, and maximizing product quality.

FAQ

What are the most common reasons for short shots in plastic injection molding?

The most common reasons for short shots include insufficient injection pressure, which fails to push the molten plastic to fully fill the mold cavity. Low plastic melt temperature or high mold temperature can reduce plastic fluidity, making it difficult for the plastic to flow smoothly. Poor mold design, such as a long or narrow runner system, can create high flow resistance. Additionally, issues like a blocked nozzle or improper venting can also contribute to short shots. For example, in a mold with a long and complex runner system, the plastic may cool down and solidify before reaching all parts of the cavity, resulting in a short shot.

How can we effectively prevent the occurrence of flash?

To prevent flash, first, carefully adjust the injection pressure and temperature. High injection pressure or temperature can cause the plastic to flow into the gaps between mold components, so keep them within the appropriate range. Regularly check the mold closure. Worn - out mold components, misaligned mold plates, or insufficient clamping force can lead to gaps for flash to occur. Ensure the mold is well - maintained and the clamping force is sufficient. Optimize the mold design. For instance, proper venting and well - designed parting lines can help prevent flash by reducing the chances of plastic overflow.