What is Injection Molding Tooling?

Injection molding tooling is the heart of plastic manufacturing. It's a set of precisely engineered components that work in harmony to create the countless plastic products we encounter daily, from the humble plastic utensils in our kitchens to the complex parts inside our cars.

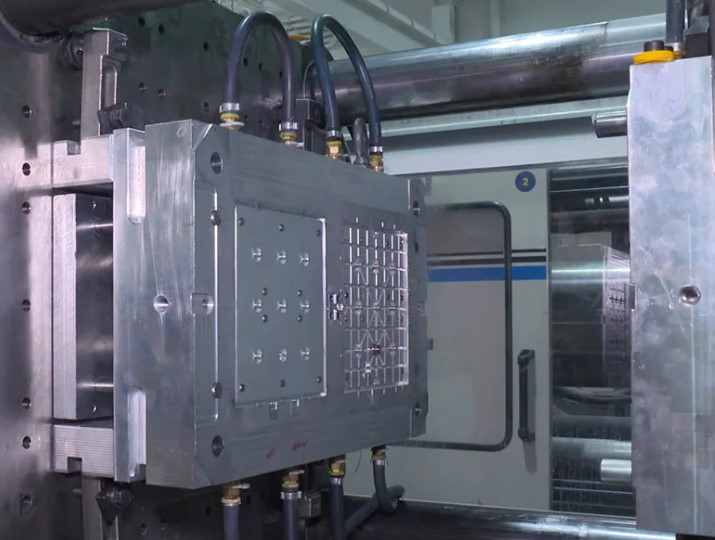

The process begins with a mold, typically made from high - grade steel or aluminum. This mold consists of two main parts: the cavity and the core. The cavity is the negative impression of the final product, while the core forms the internal features. For example, when making a plastic bottle cap, the cavity defines the outer shape of the cap, and the core creates the inner threads.

Once the mold is ready, plastic pellets are fed into an injection molding machine. These pellets are heated until they reach a molten state, becoming a highly viscous liquid. The machine then injects this molten plastic into the mold cavity at high pressure. The plastic fills every nook and cranny of the mold, taking on its shape. After that, the mold is cooled, usually with water circulation systems built into the mold itself. As the plastic cools, it solidifies, and the final product is formed. Finally, the mold opens, and the product is ejected, ready for further inspection or processing.

Key Aspects of Injection Molding Tooling

1. Mold Design

Mold design is the cornerstone of successful injection molding. It requires a deep understanding of the product's intended use, as well as a meticulous approach to geometry and functionality. When designing a mold, engineers must consider several factors.

Product Structure: The complexity of the product's structure directly impacts the mold design. For instance, a plastic part with intricate internal features like a multi - chambered container will need a mold with a more elaborate core design. Special techniques such as side - action mechanisms may be required to create undercuts or holes in the side walls of the product. This involves using movable cores or slides that can retract after the plastic has solidified, allowing the part to be ejected from the mold without damage.

Dimensions and Tolerances: Precision is crucial in injection molding. The mold must be designed to achieve the exact dimensions of the final product within the specified tolerance range. High - precision parts, like those used in medical devices or electronics, demand molds with extremely tight tolerances, often in the range of ±0.01mm. Even a slight deviation can lead to issues such as poor fit in assemblies or malfunction of the final product.

2. Material Selection

The choice of material for injection molding tooling is a decision that can significantly influence the quality, cost, and lifespan of the molds. Here are some commonly used materials and their characteristics:

| Material | Advantages | Disadvantages |

| Steel | High strength and hardness, can withstand high - pressure injection processes. Long lifespan, suitable for high - volume production. Excellent wear resistance, maintaining dimensional accuracy over time. | High cost, both in terms of raw material and machining. Heavier, which may pose challenges in handling and require more powerful injection molding machines. Longer heat - up and cool - down times due to its high thermal conductivity. |

| Aluminum | Lightweight, making it easier to handle and reducing the overall weight of the mold. Good thermal conductivity, leading to faster cooling cycles and potentially higher production rates. Lower cost compared to some high - grade steels. | Lower hardness than steel, which means it may wear out more quickly, especially for parts with high - friction surfaces. Not as suitable for very high - pressure injection or long - term, high - volume production runs. |

| Copper - based Alloys | Exceptional thermal conductivity, enabling rapid cooling of the plastic within the mold. This can lead to shorter cycle times and higher productivity. Good corrosion resistance in certain environments. | Relatively soft, so they may not be suitable for molds that need to withstand high mechanical stresses. Higher cost than aluminum in many cases. |

When selecting a material, manufacturers must balance factors such as the production volume, the complexity of the parts, and the required surface finish. For low - volume production or prototypes, aluminum might be a cost - effective choice. In contrast, high - volume production of durable parts would benefit more from steel molds.

3. Manufacturing Process

The manufacturing process of injection molding tooling is a multi - step procedure that demands high - precision machining and strict quality control.

Machining Processes:

- Milling: This is a fundamental process where rotating cutters are used to remove material from the mold block, shaping it into the desired form. CNC (Computer Numerical Control) milling machines are commonly employed to achieve high precision. For example, when creating the cavity of a mold, the milling process can accurately carve out the complex 3D shape of the final product.

- Drilling and Boring: Holes are drilled for various purposes, such as for cooling channels, ejector pins, or for mounting the mold on the injection molding machine. Boring is used to enlarge and finish the drilled holes to the required diameter and surface finish.

- Electrical Discharge Machining (EDM): EDM is a specialized process used for creating intricate shapes or features that are difficult to machine conventionally. In EDM, an electric spark is used to erode the material, allowing for the creation of sharp corners, fine details, or complex internal geometries.

Precision Control:

Throughout the manufacturing process, maintaining tight tolerances is essential. Advanced measuring tools like coordinate measuring machines (CMMs) are used to regularly check the dimensions of the mold components. These machines can measure with an accuracy of up to ±0.001mm, ensuring that the mold meets the exact specifications required for the injection molding process. Additionally, quality control inspections are carried out at each stage of production to catch any potential defects early on, minimizing costly rework or scrap.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology brings a wealth of experience and unique advantages to the field of injection molding tooling.

With advanced technology at its core, Yigu Technology stays ahead of the curve. We employ state - of - the - art CAD/CAM systems for mold design, ensuring high - precision and efficient creation of complex mold geometries. This not only reduces the design cycle but also minimizes errors, leading to more accurate and reliable molds. For instance, our use of advanced simulation software allows us to predict potential molding issues in the design phase and make necessary adjustments, saving time and cost during the actual production.

In terms of service, Yigu Technology is committed to providing top - notch support to our clients. We offer comprehensive pre - sales consultation, working closely with customers to understand their product requirements and providing professional advice on mold design and material selection. During the production process, we maintain strict quality control and keep clients informed of the progress at all times. Our after - sales service is equally remarkable, with a dedicated team ready to address any issues promptly, ensuring the smooth operation of our clients' production lines. Whether it's a small - scale project or a large - volume production run, Yigu Technology has the expertise and resources to deliver high - quality injection molding tooling solutions that meet and exceed customer expectations.

FAQ

1. What factors should be considered when choosing injection molding tooling materials?

When choosing injection molding tooling materials, several factors come into play. Mold Life: For high - volume production, materials like steel with high strength and wear - resistance are preferred as they can withstand long - term use. Cost: Aluminum is generally more cost - effective than high - grade steel, making it a good choice for low - volume production or prototypes. Product Requirements: If the product has high - precision requirements or complex geometries, the material's machinability and ability to maintain tight tolerances are crucial. Additionally, the material's thermal conductivity affects the cooling rate of the plastic, which in turn impacts the production cycle.

2. How to reduce the occurrence of defects in injection - molded plastic products?

There are multiple ways to reduce defects. Optimize Mold Design: A well - designed mold with proper gating, venting, and cooling systems can prevent issues like short shots, warping, and sink marks. For example, ensuring that the flow of molten plastic is uniform throughout the mold cavity by carefully designing the runner system. Control Process Parameters: Maintaining the right temperature, pressure, and injection speed is essential. Too low a temperature can cause the plastic to solidify prematurely, while excessive pressure may lead to flash or over - packing. Regularly calibrating the injection molding machine and closely monitoring these parameters during production can significantly reduce defect rates.

3. Can injection molding tooling be used for small - batch production?

Yes, injection molding tooling can be used for small - batch production, but there are considerations. The high cost of mold manufacturing may seem less economical for small batches. However, if the product has complex shapes or high - quality requirements, injection molding can still be a viable option. In such cases, using less expensive materials like aluminum for the mold can help reduce costs. Additionally, advanced design techniques and rapid prototyping methods can speed up the mold - making process, making it more suitable for small - batch production. It's also important to optimize the production process to minimize waste and ensure efficient use of resources during small - scale runs.