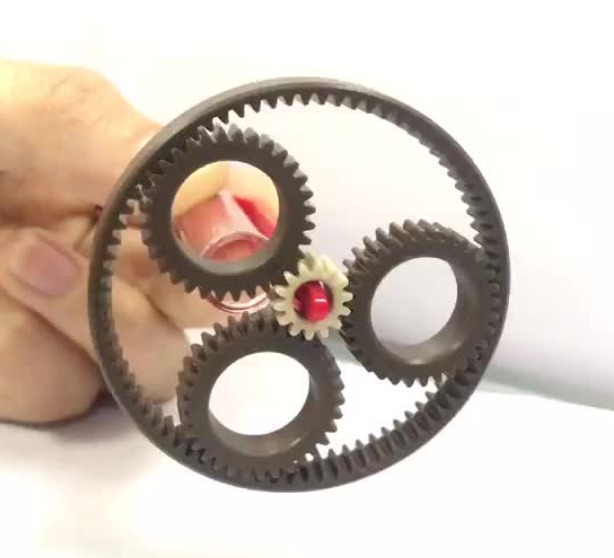

What Advantages Material Considerations of Plastic Miter Gears?

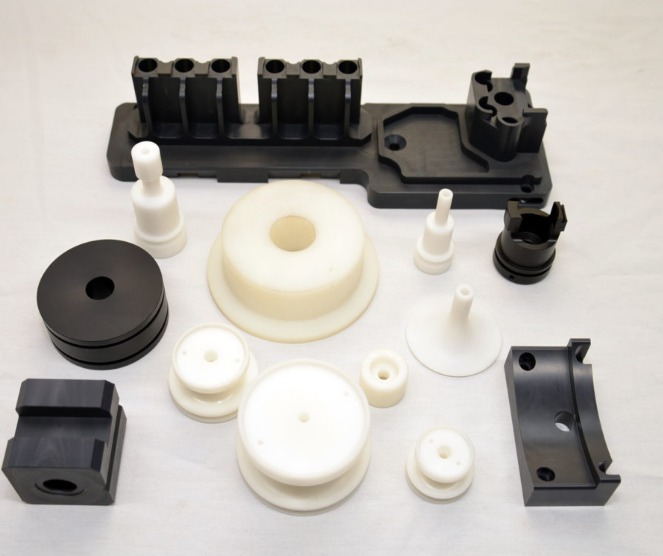

Introduction What are Plastic Miter Gears? Plastic miter gears are a type of bevel gears with teeth cut at a right angle to their axis, typically 45 degrees, designed to transmit motion and power between two intersecting shafts, usually at a 90 - degree angle. They are made from various types of plastics, which endows […]