How Does the Double-Shot Injection Molding Process Work?

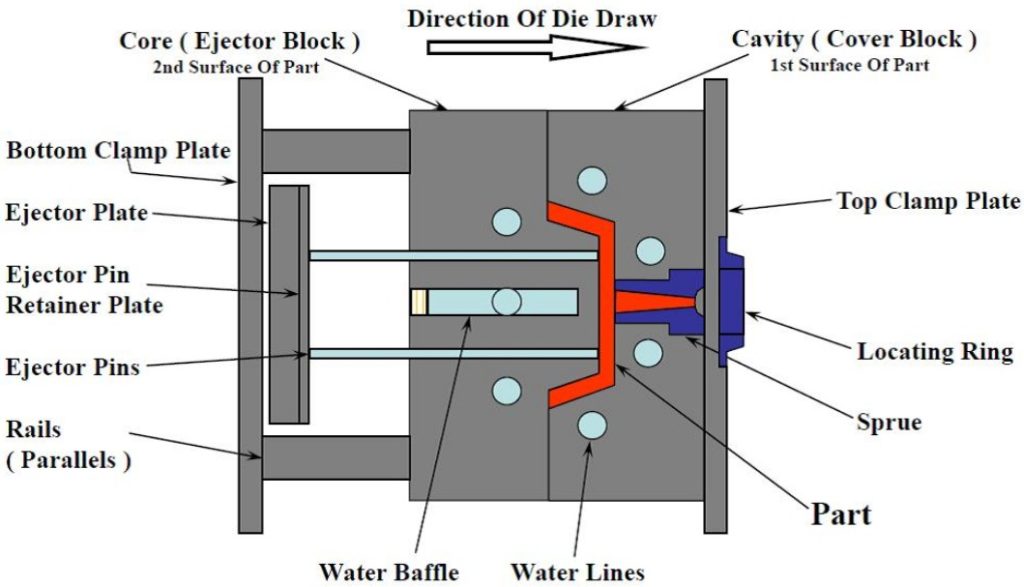

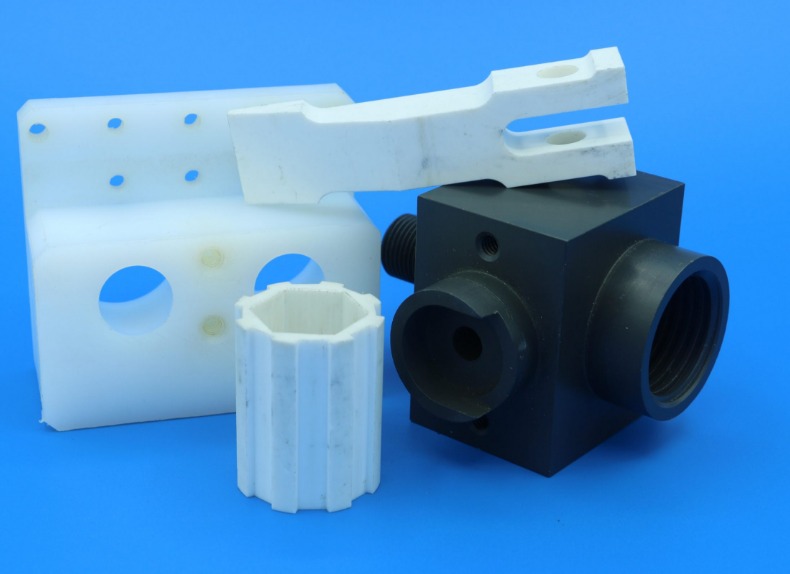

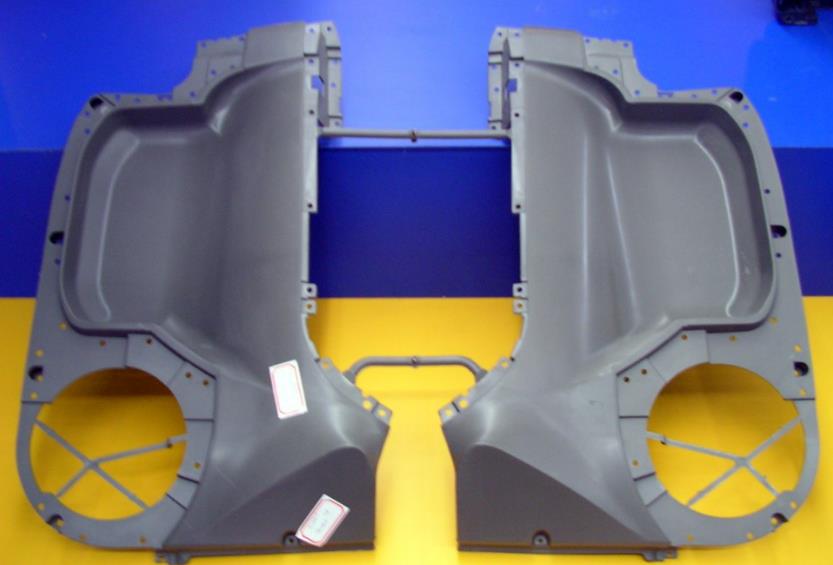

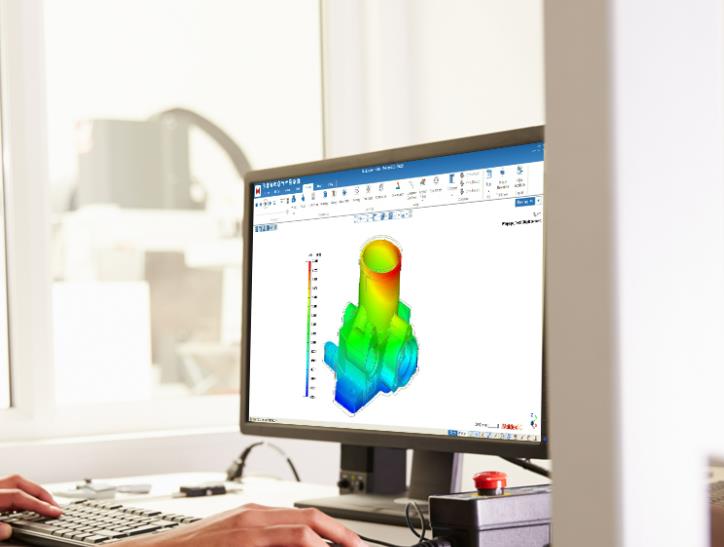

Double-Shot Injection Molding (also known as two-shot or 2K molding) is a sophisticated manufacturing process that redefines part complexity and functionality. By sequentially injecting two different materials into a single mold, it creates seamless, multi-material components in one efficient cycle. This technology unlocks possibilities unattainable by traditional assembly—think soft-touch grips fused to rigid frames, multi-colored […]