Manufacturers working with high-pressure molding or heat-sensitive parts often face a frustrating trade-off: choosing between materials with good thermal conductivity and those with sufficient strength. Standard copper alloys may conduct heat well but lack the hardness to withstand repeated high-pressure cycles, while stronger metals like steel fail to dissipate heat quickly enough, leading to long cycle times and part defects. This is where Ampco 940 (Cu-Be) stands out. As a premium copper-nickel-silicon-chromium alloy, Ampco 940 combines exceptional thermal conductivity with impressive strength and hardness, solving the critical pain points of high-performance mold applications. In this guide, we’ll explore how Ampco 940 excels in demanding scenarios, its unique properties, and how to leverage its capabilities to enhance mold performance.

Introduction to Ampco 940 (Cu-Be)

Ampco 940 (Cu-Be) is a high-performance copper alloy engineered for applications requiring a rare balance of thermal conductivity, strength, and wear resistance:

- Definition: Ampco 940 is a precipitation-hardened copper alloy, formulated with nickel, silicon, and chromium to enhance strength and hardness while retaining excellent thermal and electrical conductivity. Unlike traditional beryllium copper, it achieves its properties without beryllium, making it more environmentally friendly.

- Standard specifications: Ampco 940 complies with RWMA Class 3 standards, which specify requirements for resistance welding materials. Its chemical composition includes 96% copper, 2.5% nickel, 0.7% silicon, and 0.4% chromium, ensuring consistent performance across batches.

- Supplier brands: Ampco Metal Inc. (USA) is the primary manufacturer, with a reputation for precision alloy development. The company produces Ampco 940 in rods, plates, and custom shapes tailored for mold components like cooling pins and injection nozzles.

- Industry usage: Ampco 940 is widely used in 10-15% of high-pressure molds, particularly in plastic injection molding, cold-chamber die casting, and resistance welding. Its ability to handle 20,000+ psi pressures while dissipating heat quickly makes it a top choice for automotive and electronics manufacturing.

- Comparison with other copper alloys: Compared to beryllium copper (C17200), Ampco 940 offers similar strength (689 MPa tensile strength vs. 690 MPa) with comparable thermal conductivity (208 W/m-K vs. 200-250 W/m-K) but without beryllium’s toxicity. It’s harder than chromium copper (380 HBV vs. 200-250 HBV) and more wear-resistant than standard copper-tungsten alloys, making it ideal for high-cycle applications.

Properties of Ampco 940 (Cu-Be)

The properties of Ampco 940 (Cu-Be) make it a standout choice for demanding mold applications:

- High thermal conductivity: At 208 W/m-K, Ampco 940 conducts heat significantly better than steel (40-50 W/m-K) and nearly as well as pure copper (401 W/m-K). This rapid heat dissipation reduces cooling times by 25-30% compared to steel molds, cutting overall cycle times for thin-walled parts.

- High electrical conductivity: With 48% IACS (International Annealed Copper Standard) conductivity, Ampco 940 is ideal for molds requiring in-mold heating or sensor integration, such as those used in thermoforming and resistance welding.

- High tensile strength: Ampco 940 achieves a tensile strength of up to 689 MPa, surpassing most copper alloys and even some low-carbon steels. This strength allows it to withstand high injection pressures (up to 25,000 psi) without deformation, extending mold life in high-volume production.

- High hardness: At 380 HBV (Brinell Hardness Value), Ampco 940 is significantly harder than standard copper alloys (100-200 HBV) and even some aluminum grades (95-105 HBV for 6061-T6). This hardness minimizes wear from repeated contact with molten plastic or metal, reducing maintenance needs.

- Good corrosion resistance: Ampco 940 resists corrosion from water-based coolants, mild chemicals, and humidity, outperforming uncoated steel in damp production environments. This resistance ensures consistent thermal conductivity over time, as corrosion-free surfaces transfer heat more efficiently.

- Thermal expansion coefficient: With a coefficient of 17.5 μm/m-°C, Ampco 940 expands slightly more than steel but less than aluminum, making it compatible with multi-material mold designs when proper clearances are included.

Applications of Ampco 940 (Cu-Be) in Mold Making

Ampco 940 (Cu-Be) excels in applications where strength and thermal management are equally critical:

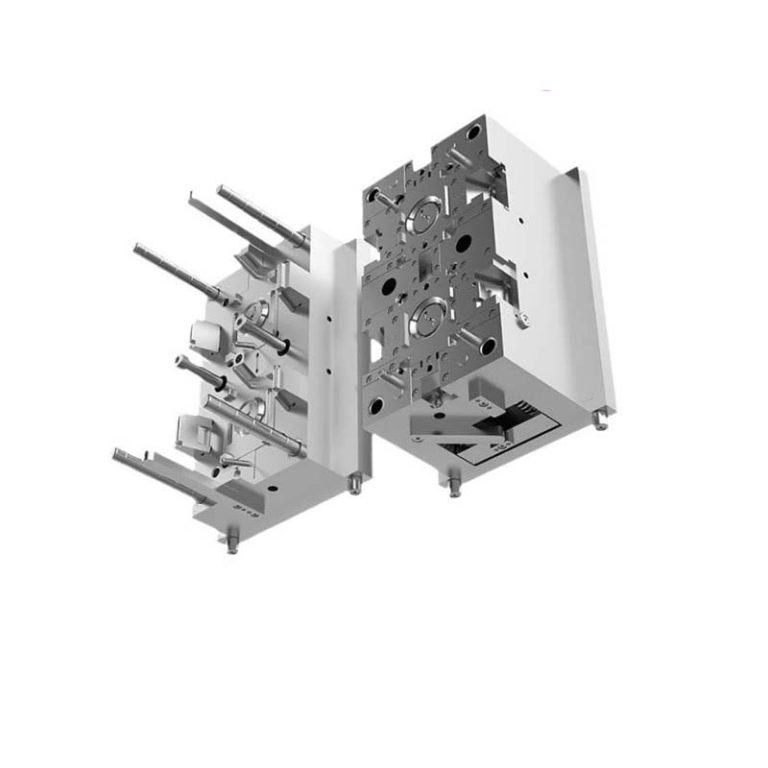

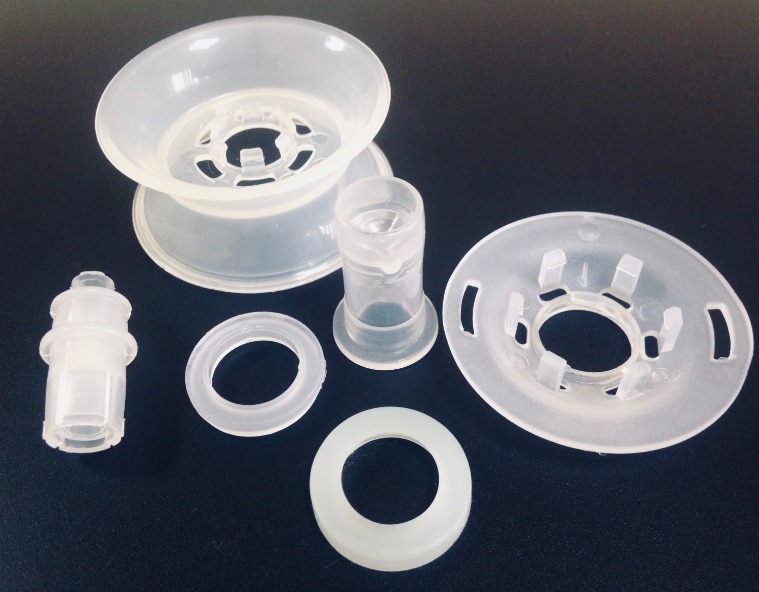

- Plastic injection molding components: Ampco 940 is ideal for injection nozzles, cooling pins, and mold inserts, where its thermal conductivity accelerates cooling of heat-sensitive plastics like polycarbonate and nylon. Its hardness prevents wear from abrasive additives in engineering plastics.

- Blow molding: For blow molds producing large, thin-walled parts (e.g., automotive fuel tanks, industrial containers), Ampco 940’s strength resists deformation during high-pressure air inflation, while its thermal conductivity ensures uniform cooling and consistent part dimensions.

- Resistance welding tips and fixtures: Ampco 940’s combination of electrical conductivity and hardness makes it perfect for resistance welding tools, where it withstands repeated high-current, high-pressure cycles without degradation.

- Cold-chamber aluminum die-casting machines: In die casting, Ampco 940 components (e.g., shot sleeves, plungers) resist wear from molten aluminum while dissipating heat quickly, reducing cycle times and extending tool life.

- Paper winding rolls: For industrial paper processing, Ampco 940 rolls maintain uniform pressure and heat distribution, preventing paper tearing or uneven winding—thanks to the alloy’s strength and thermal stability.

Machining and Fabrication of Ampco 940 (Cu-Be)

Machining and fabrication of Ampco 940 require attention to its hardness, but the process is manageable with proper techniques:

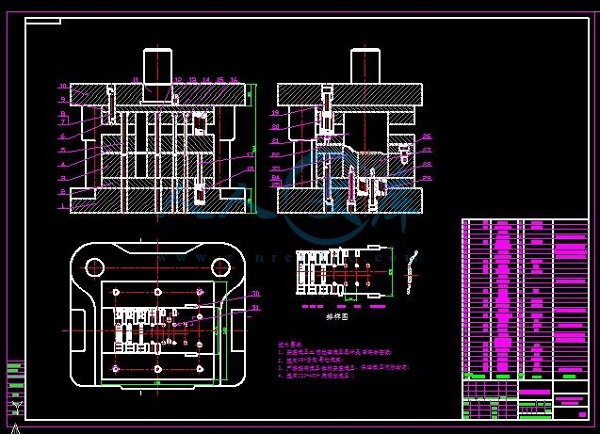

- Precision machining: Ampco 940 machines best with carbide tools due to its high hardness. Use cutting speeds of 100-150 SFM and light feeds to minimize tool wear, with coolant to prevent heat buildup. This ensures clean cuts and maintains tight tolerances (±0.0002 inches).

- CNC milling: 3-axis and 5-axis CNC milling are suitable for complex geometries, though rigid setups are necessary to avoid tool deflection. Adaptive milling strategies, which adjust feed rates based on cutting forces, help maintain precision in intricate features.

- EDM (Electrical Discharge Machining): EDM works effectively with Ampco 940, producing precise details with minimal burring. Its high electrical conductivity requires lower current settings to prevent excessive electrode wear, but the process remains faster than with steel.

- Grinding: Silicon carbide wheels are recommended for grinding Ampco 940, with a 400-grit wheel achieving Ra 0.05 μm surface finish. Light pressure prevents wheel clogging and ensures consistent results.

- Surface finishing: Ampco 940 polishes to a smooth finish (Ra 0.02-0.05 μm) with 600-grit sandpaper and a buffing wheel. No additional plating is needed for most applications, though nickel plating can enhance wear resistance in extreme conditions.

- No additional heat treatment required: A key advantage of Ampco 940 is its ready-to-use hardness. Unlike some copper alloys, it requires no post-machining heat treatment, reducing production time and eliminating the risk of distortion.

Maintenance and Repair of Ampco 940 (Cu-Be) Molds

Proper maintenance and repair ensure Ampco 940 molds retain their performance over extended use:

- Welding repair: Ampco 940 can be welded using Ampco-Trode 940 filler wire or Ampco-Trode 940 laser wire, which match the alloy’s composition. This restores worn or damaged areas without compromising strength or thermal conductivity.

- Welding with stainless steel: When joining Ampco 940 to stainless steel components, use Ampco-Trode 10 filler, which ensures a strong bond and prevents galvanic corrosion between the dissimilar metals.

- Mold cleaning: Clean Ampco 940 surfaces with mild detergents and soft brushes to remove plastic residue or debris. Avoid abrasive cleaners, which can scratch the surface and reduce thermal conductivity.

- Preventive maintenance: Inspect Ampco 940 components monthly for signs of wear, especially in high-pressure areas like injection nozzles. Polishing worn surfaces restores their thermal performance and prevents part defects.

- Inspection: Use ultrasonic testing to detect internal cracks or voids, which can compromise strength and heat transfer. Visual checks for corrosion or tarnish ensure cooling channels remain unobstructed.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends Ampco 940 for clients needing high-strength, thermally efficient mold components. We’ve found it particularly effective in automotive injection molds, where its 208 W/m-K thermal conductivity reduces cycle times by 25% for thin-walled parts. Its 689 MPa tensile strength withstands 20,000+ psi pressures, outperforming standard copper alloys in durability. While Ampco 940 costs more upfront, its longer life and improved part quality make it cost-effective for high-volume runs. Our team uses carbide tools and EDM to achieve tight tolerances, ensuring seamless integration with steel or aluminum molds. For demanding applications, Ampco 940 delivers unmatched performance.

FAQs

- How does Ampco 940 compare to beryllium copper in terms of safety?

Ampco 940 is safer than traditional beryllium copper, as it contains no beryllium—a toxic material requiring special handling. This makes it easier to work with and more environmentally friendly, while still offering comparable strength and conductivity.

- Can Ampco 940 be used in food-grade or medical mold applications?

Yes—Ampco 940’s copper-based composition, with no toxic additives, meets FDA standards for indirect food contact. Its corrosion resistance also makes it suitable for medical device molds requiring frequent cleaning with mild disinfectants.

- What’s the maximum number of cycles an Ampco 940 mold component can handle?

Ampco 940 components last 100,000-200,000 cycles for non-abrasive plastics, far exceeding standard copper alloys (50,000-100,000 cycles). For abrasive materials like glass-filled plastics, expect 50,000-80,000 cycles with proper maintenance.