Understanding the Basics of Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. The plastic is then cooled and solidified within the mold, taking on the shape of the cavity. Once the plastic has hardened, the mold is opened, and the finished part is ejected. This process is highly efficient and can produce a large number of identical parts with high precision and consistency.

The process begins with the selection of the appropriate plastic material. There are numerous types of plastics available, each with its own unique properties such as strength, flexibility, heat resistance, and chemical resistance. The choice of material depends on the specific requirements of the final product, including its intended use, performance expectations, and environmental conditions it will be exposed to.

For example, if you're manufacturing a product that needs to withstand high temperatures, like a coffee maker component, you might choose a heat - resistant plastic such as polyphenylene sulfide (PPS). On the other hand, for a flexible and lightweight product like a plastic toy, a material like polyethylene (PE) could be a better fit.

The mold, which is typically made of steel or aluminum, is another crucial element. It consists of two halves: the cavity, which forms the outer shape of the part, and the core, which forms the inner shape. The design of the mold determines the complexity and accuracy of the final product. Molds can be simple for basic shapes or highly intricate for products with complex geometries, undercuts, or internal features.

A custom plastic injection molding manufacturer plays a vital role in this process. They are responsible for everything from the initial design and mold creation to the actual injection molding and post - processing of the parts. A good manufacturer will have in - depth knowledge of different plastic materials, advanced mold - making capabilities, and state - of - the - art injection molding equipment. They can provide valuable advice on material selection, help optimize the product design for manufacturability, and ensure high - quality production runs. For instance, they might suggest design modifications to reduce the number of mold components or to improve the flow of plastic during injection, which can ultimately save costs and improve the quality of the final product.

Key Factors to Consider

Experience and Expertise

When evaluating a custom plastic injection molding manufacturer, experience is a fundamental factor. A manufacturer with a long - standing presence in the industry, say, one that has been in business for over 10 years, is likely to have encountered and resolved a wide range of production challenges. For example, a company established in 2005 has had time to refine its processes, build a reliable supply chain, and train its workforce.

Service across multiple industries is also a strong indicator of expertise. A manufacturer that has served sectors such as automotive, electronics, and medical can draw on diverse knowledge. In the automotive industry, parts need to meet high - impact resistance and heat - tolerance standards. In electronics, components often require tight dimensional tolerances for precise fitting within devices. A manufacturer with such cross - industry experience can adapt to different product requirements more effectively. Customer case studies are tangible proof of a manufacturer's capabilities. If a manufacturer has successfully produced high - volume, high - precision parts for well - known companies, it demonstrates their ability to meet strict quality and production demands.

Quality Assurance

Quality assurance is non - negotiable in plastic injection molding. Quality certifications, like ISO 9001, are important as they signify that a manufacturer has a structured quality management system in place. This system covers everything from raw material inspection to final product testing. For instance, an ISO - certified manufacturer must have documented procedures for handling non - conforming products, which ensures that any defective items are identified and corrected promptly.

A robust quality control process is equally crucial. This includes in - line inspections during production, where trained quality control staff check for common defects such as flash (excess plastic), short shots (incomplete filling of the mold), and warping. They use tools like calipers, gauges, and optical inspection devices to measure and assess the quality of parts. Additionally, a manufacturer should have advanced testing equipment. For example, a tensile testing machine can determine the strength of plastic parts, while a thermal analysis device can evaluate a part's heat resistance, ensuring that the final products meet the required performance standards.

Production Capacity

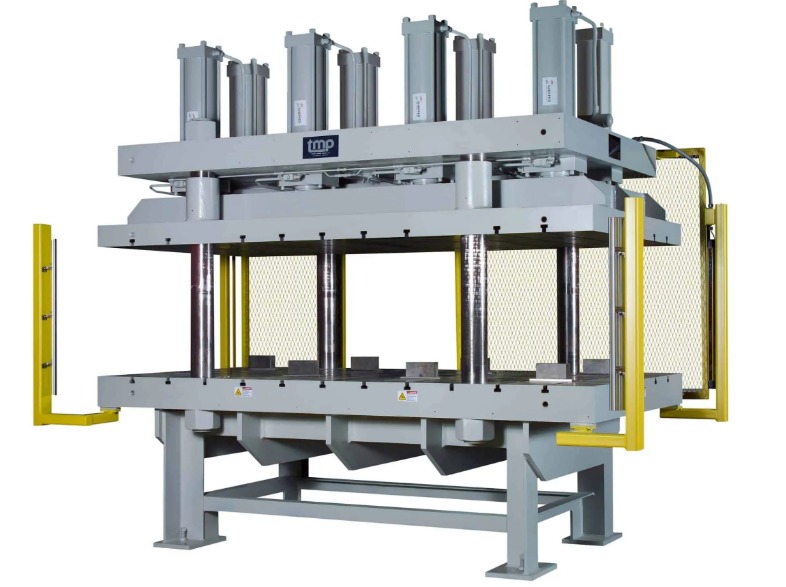

The production capacity of a custom plastic injection molding manufacturer is a key consideration, especially for large - scale or time - sensitive projects. The number and specifications of injection molding machines directly impact capacity. A manufacturer with a fleet of 50 injection molding machines, including large - sized machines with a clamping force of 3000 tons or more, can handle large - scale production runs. These high - capacity machines are suitable for manufacturing large parts like automotive bumpers or industrial equipment housings.

The maximum injection volume of the machines also matters. If a project requires the production of large, thick - walled parts, a machine with a high maximum injection volume is essential. Moreover, the ability to scale production up or down according to order size is valuable. A manufacturer should be able to quickly ramp up production for a sudden large order and efficiently manage smaller orders without sacrificing quality or incurring excessive costs.

Cost - Effectiveness

Cost is a significant factor when choosing a custom plastic injection molding manufacturer. The cost of the mold is often a substantial upfront expense. A simple mold for a basic plastic part might cost a few thousand dollars, while a complex mold with intricate features, such as those for a medical device component, could cost tens of thousands of dollars. However, a more expensive mold may be more cost - effective in the long run if it has a longer lifespan and can produce a higher volume of parts with consistent quality.

The unit cost of each product is another crucial aspect. This is influenced by factors like material costs, production efficiency, and labor costs. A manufacturer that can source high - quality raw materials at a competitive price and has optimized its production processes to minimize waste and reduce cycle times will offer a lower unit cost. For example, by using advanced automation technology, a manufacturer can reduce labor costs and increase production speed, ultimately lowering the cost per part. Additionally, some manufacturers may offer cost - saving suggestions, such as using a different but equivalent plastic material that is more affordable without sacrificing product performance.

Technological Capabilities

In today's rapidly evolving manufacturing landscape, technological capabilities play a vital role. Advanced mold design software, such as CAD (Computer - Aided Design) and CAM (Computer - Aided Manufacturing), enables manufacturers to create highly precise and efficient molds. With CAD software, designers can create 3D models of the mold, simulate the injection process, and identify potential issues like flow problems or air traps before the mold is actually built. This not only saves time but also reduces the need for costly mold revisions.

Automation in the production process is also a game - changer. Automated material handling systems can precisely measure and feed the plastic pellets into the injection molding machines, reducing human error and ensuring consistent product quality. Robotic arms can be used for tasks like part removal from the mold, assembly, and quality inspection, increasing production speed and accuracy. Moreover, a manufacturer's ability to work with new and innovative plastic materials is a plus. For example, as biodegradable plastics gain popularity, a manufacturer that can master the injection molding process for these materials can offer more sustainable product solutions to clients.

Customer Service

Exceptional customer service can make a significant difference in the success of a project. A manufacturer that responds promptly to inquiries, preferably within 24 hours, shows that they value their clients. This quick response time is crucial, especially when clients have urgent questions about product design, production timelines, or pricing.

Technical support is another important aspect. A knowledgeable technical team can provide valuable advice on product design for manufacturability. For example, they can suggest design modifications to reduce the complexity of the mold, which can save costs and improve the production process. After - sales service is equally vital. A manufacturer should offer a reasonable warranty period, typically 1 - 2 years, during which they will address any product quality issues. They should also provide easy - to - access support channels, such as a dedicated customer service hotline or an online support portal, to ensure that clients' concerns are resolved efficiently.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the significance of choosing the right custom plastic injection molding manufacturer. For us, seamless cooperation is key. A manufacturer should be able to work closely with us, understand our unique requirements, and provide timely feedback. This collaborative approach ensures that the final products meet our high - standards.

Moreover, the ability to handle special requests is crucial. In the non - standard product manufacturing field, we often have complex designs and specific material requirements. A reliable injection molding manufacturer should have the technical capabilities and flexibility to accommodate these special needs. Whether it's working with new materials or creating intricate molds, they should be up to the task. This not only guarantees the quality of the products but also helps us expand our product offerings and meet the diverse demands of our clients.

FAQ

What is the typical lead time for a custom plastic injection molding project?

The lead time for a custom plastic injection molding project can vary widely. On average, for a standard project with a relatively simple mold and no complex design requirements, it may take around 4 - 6 weeks from the initial order placement to the delivery of the first batch of products. This includes the time for mold design, mold manufacturing, material procurement, and the initial production runs.

However, several factors can influence the lead time. Complex mold designs, especially those with intricate geometries or multiple moving parts, can extend the mold - making process by 2 - 4 weeks. For example, a mold with internal slides and undercuts for a highly detailed automotive interior component will take longer to fabricate compared to a basic mold for a simple plastic container. Additionally, if there are delays in material procurement, perhaps due to shortages of a specific type of plastic resin, the lead time can be further extended by 1 - 3 weeks. High - volume orders also generally require more production time, which can add another 1 - 2 weeks to the overall lead time.

How can I ensure the color accuracy of the plastic products?

To ensure color accuracy in plastic products, start with the selection of a reliable color standard. Most manufacturers use industry - recognized color systems like Pantone. When specifying the color, provide the exact Pantone number or other detailed color specifications.

Before mass production, request a color sample or prototype. A good manufacturer will be able to create a small - scale sample using the actual plastic material and the proposed coloring method, whether it's through the use of color masterbatches or liquid colorants. This sample allows you to visually inspect and approve the color before full - scale production begins.

During production, the manufacturer should have a quality control process in place to monitor color consistency. This may involve using color measurement instruments such as spectrophotometers, which can precisely measure the color of the plastic parts and compare it to the approved color standard. Regular checks, for example, every hour during production, can help detect any color drift early on, allowing for adjustments to be made to the coloring process to maintain accuracy.

What are the common defects in plastic injection molding and how to avoid them?

Common defects in plastic injection molding include flash (excess plastic around the edges of the part), bubbles (voids within the plastic), and shrinkage (areas where the plastic has pulled away from the mold surface).

Flash often occurs when the injection pressure is too high or the mold is not properly sealed. To avoid it, the manufacturer can optimize the injection pressure and ensure the mold is well - maintained and tightly closed. Checking the mold for wear and tear regularly, and replacing any damaged or worn - out parts, can prevent flash from occurring.

Bubbles are typically caused by trapped air or volatile gases in the plastic. To prevent bubbles, proper material drying is crucial. If the plastic material has absorbed moisture, it can release steam during the injection process, creating bubbles. Drying the plastic pellets to the recommended moisture content, usually specified by the material supplier, can solve this problem. Additionally, improving the mold's venting system, such as adding vent holes in appropriate locations, can help release trapped air during injection.

Shrinkage happens when the plastic cools and contracts unevenly. To avoid shrinkage, maintaining a consistent temperature throughout the mold and the plastic material is essential. A well - designed cooling system in the mold, with evenly distributed cooling channels, can ensure uniform cooling. Adjusting the injection and holding pressures can also help compensate for the shrinkage, ensuring that the plastic fills the mold cavity completely during the cooling process.