What is Injection Moulding?

Injection moulding is a manufacturing process widely used for producing parts in large quantities. This highly efficient method involves injecting molten material, typically plastic, into a mould cavity. Once the material fills the cavity, it cools and solidifies, taking on the precise shape of the mould.

The process begins with the plastic material, which comes in the form of small pellets. These pellets are fed into a heated barrel, where they are melted into a viscous liquid state. A reciprocating screw or a plunger then exerts high pressure, forcing the molten plastic through a nozzle and into the closed mould. The mould, usually made of steel or aluminium, consists of two halves that are precisely machined to create the desired shape of the final product.

Once the cavity is filled, the plastic is held under pressure for a short period to ensure complete filling and proper packing. As the plastic cools, it solidifies, and the mould is opened. The newly formed part, now in its final shape, is ejected from the mould. The cycle then repeats, with the mould closing again for the next injection.

Injection moulding is a cornerstone of modern manufacturing, enabling the production of a vast array of products with high precision, consistency, and speed. It has revolutionized industries by allowing for the mass production of complex and customized parts, making it an essential process in the manufacturing landscape.

Common Injection Moulded Products

Injection moulding is a versatile manufacturing process that is used to create a wide range of products across various industries. Here are some of the most common products that are injection moulded:

Consumer Goods

In the realm of consumer goods, injection moulding plays a pivotal role. Plastic cutlery, for example, is a common household item that is often injection moulded. These products are lightweight, cost - effective, and can be produced in large quantities. Injection moulding allows for the creation of intricate designs, such as ergonomic handles on knives and forks, enhancing user comfort. The process also ensures consistent quality, with each piece having the same shape, size, and finish.

Toys are another significant category. Injection moulding enables the production of toys with complex shapes, moving parts, and vibrant colors. For instance, action figures with detailed facial features and articulated joints can be precisely moulded. The high production speed of injection moulding is crucial for the toy industry, as it can meet the high demand during peak seasons like Christmas. According to industry reports, the global toy market, which heavily relies on injection - moulded toys, was valued at over $90 billion in 2022 and is expected to grow steadily.

Automotive Parts

The automotive industry benefits greatly from injection moulding. Dashboards are a prime example. They are typically made from materials like polypropylene (PP) or acrylonitrile - butadiene - styrene (ABS) through injection moulding. This process allows for the integration of various features, such as instrument clusters, air vents, and storage compartments, into a single unit. Injection - moulded dashboards are lightweight, which helps to improve fuel efficiency. They also contribute to the overall safety and comfort of the vehicle, as they can be designed to absorb impact energy and provide a smooth, aesthetically pleasing interior.

Bumpers are another critical automotive component. Injection - moulded bumpers are made from materials with high impact resistance, such as thermoplastic elastomers (TPEs). They can be shaped to fit the specific design of a vehicle, providing both protection and an aesthetic appeal. In the production of vehicles, injection moulding speeds up the manufacturing process, as bumpers can be produced quickly and in large numbers. This efficiency reduces production costs and allows automotive manufacturers to meet high - volume demands.

Electronic Components

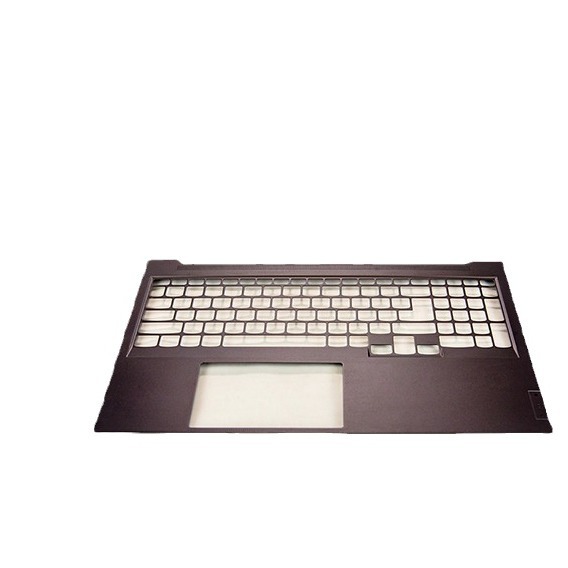

In the world of electronics, injection moulding is essential for creating phone cases and computer keyboards. Phone cases are often injection - moulded from materials like polycarbonate (PC) or silicone. PC cases offer high strength and scratch resistance, while silicone cases provide good shock absorption. Injection moulding allows for the production of cases with precise cutouts for ports, buttons, and cameras, ensuring a perfect fit for the phone.

Computer keyboards are also commonly injection - moulded. The keys, keycaps, and the keyboard housing can all be produced through this process. Injection - moulded keycaps can have high - quality printing for the characters, and the housing can be designed to be thin and lightweight while still providing structural integrity. This not only improves the functionality of the keyboard but also its appearance, making it more appealing to consumers.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the significance of injection moulding. Our company specializes in providing customized solutions for a wide range of injection - moulded products.

We have a team of experienced engineers and state - of - the - art manufacturing equipment. This enables us to handle projects with high precision and efficiency. Whether it's a complex automotive part or a delicate electronic component, we can meet the diverse needs of our clients.

Our advantage lies in our ability to work closely with clients from the initial design stage. We offer valuable suggestions on material selection and design optimization to ensure the final product not only meets quality standards but also reduces production costs. We also provide after - sales support, ensuring that our clients are satisfied throughout the entire product life cycle.

FAQ

What types of materials are commonly used in injection moulding?

Commonly used materials in injection moulding include polypropylene (PP), which is lightweight, has good chemical resistance, and is often used in automotive parts, consumer goods like food containers. Acrylonitrile - Butadiene - Styrene (ABS) is another popular choice. It combines the strength of acrylonitrile, the toughness of butadiene, and the processability of styrene, making it suitable for products such as electronics housings, toys, and automotive interior components. Polycarbonate (PC) offers high strength, heat resistance, and optical clarity, so it's frequently used in applications like safety goggles, lenses, and some electronic device parts. Polystyrene (PS) is easy to process, has good transparency, and is often used in disposable products like plastic cutlery and packaging.

How long does it take to produce an injection moulded product?

The production time of an injection - moulded product depends on several factors. The complexity of the product and the mould is a major factor. Simple products with basic moulds can have a short cycle time, perhaps as little as 10 - 30 seconds per cycle. However, for complex products with intricate mould designs, the cycle time can be several minutes. The cooling time also plays a crucial role, as it usually accounts for a significant portion of the total cycle time, sometimes up to 80% or more. On average, for small to medium - sized, relatively simple injection - moulded products, the production time per unit can range from 15 seconds to 2 minutes, while complex or large - scale products may take 5 minutes or more per cycle.

Can injection moulding be used for small - batch production?

Injection moulding can be used for small - batch production, but it has some limitations. The main drawback is the high cost of mould manufacturing. Moulds can be expensive to design and produce, and for small - batch production, the cost per unit may be high as the mould cost is spread over a small number of products. However, if the product design is simple and the mould cost is relatively low, or if there are cost - effective ways to create the mould, such as using aluminium moulds instead of steel, injection moulding can be a viable option. Additionally, some manufacturers may offer lower - cost mould - sharing or rental options for small - batch production. In some cases, for very small batches, alternative manufacturing methods like 3D printing might be more cost - effective, but injection moulding can still be considered if the product has high - precision requirements that 3D printing may not meet.