Introduction

In the vast and dynamic realm of modern manufacturing, plastic injection mold parts have emerged as the cornerstone of innovation, efficiency, and cost - effectiveness. These parts are the result of a highly specialized manufacturing process where molten plastic is injected into a precisely designed mold cavity under high pressure. Once the plastic cools and solidifies, it takes on the intricate shape of the mold, creating a wide array of components that are integral to countless products we use daily.

From the tiniest components in our electronic devices to the large - scale parts in automotive interiors, plastic injection mold parts are everywhere. They play a crucial role in enabling mass production, which is essential for meeting the high - volume demands of the global market. In fact, according to industry statistics, over 70% of plastic products in industries such as electronics, automotive, and consumer goods are produced using plastic injection molding technology. This clearly demonstrates the indispensability of plastic injection mold parts in the manufacturing landscape.

But what exactly are the benefits that make these parts so widely adopted? In this article, we will delve deep into the various advantages of plastic injection mold parts in manufacturing, exploring how they contribute to enhanced productivity, superior product quality, cost savings, and design flexibility.

High - Precision Manufacturing

Exceptional Dimensional Accuracy

Plastic injection mold parts are renowned for their ability to achieve an exceptionally high level of dimensional accuracy. The injection molding process allows for the creation of parts with tolerances that can be as precise as ±0.05mm or even better in some advanced setups. This level of accuracy is a result of the highly controlled environment within the injection molding machine and the precision - engineered molds.

In the medical device industry, this high - precision manufacturing capability is of utmost importance. For instance, components in syringes, catheters, and implantable devices require exact dimensions. A slight deviation in the size of a catheter, for Yigu Technology example, could lead to difficulties in its insertion into blood vessels, potentially causing harm to patients. According to a study by a leading medical device manufacturer, over 95% of their plastic - molded medical components meet the strict tolerance requirements of ±0.03mm, which is essential for ensuring the safety and effectiveness of the final products.

In the electronics manufacturing sector, plastic injection mold parts are equally crucial. Consider the small plastic components in smartphones, such as the frames for cameras or the connectors for circuit boards. These parts need to be precisely sized to fit with other electronic components seamlessly. A misaligned plastic frame for a camera lens could result in a poor - quality image or even prevent the lens from functioning properly. With the continuous miniaturization of electronic devices, the demand for plastic injection mold parts with high dimensional accuracy is only increasing.

Repeatability in Production

In large - scale production, the repeatability of plastic injection mold parts is a significant advantage. Once the mold is designed and set up correctly, each part produced will be nearly identical to the previous one. This consistency is crucial for industries that require a large number of uniform components.

For example, in the automotive industry, where millions of plastic parts are produced annually for car interiors, exteriors, and engine components, the repeatability of injection - molded parts ensures that all vehicles of the same model have consistent quality. A study comparing plastic injection molding with traditional manufacturing methods like machining found that injection molding had a part - to - part variation of less than 0.1% in terms of key dimensions, while machining had a variation of around 0.5% in similar production runs. This means that plastic injection molding can produce parts with much more consistent dimensions, reducing the need for additional quality control measures to account for part - to - part variability.

The high repeatability also leads to greater efficiency in the assembly process. When parts are identical, they can be easily assembled without the need for custom - fitting or adjustment, saving both time and labor costs. In a large - scale automotive assembly line, this can translate into significant savings over the course of a year, as thousands of vehicles are assembled daily.

Cost - Efficiency

Economies of Scale

One of the most significant cost - related advantages of plastic injection mold parts is the economies of scale they offer. As the production volume of plastic injection - molded parts increases, the unit cost of each part decreases substantially. This is because the initial investment in mold design and manufacturing, which can be quite high, is spread out over a larger number of produced parts.

For Yigu Technology example, in the automotive industry, when manufacturing plastic interior components such as dashboard panels. A high - quality injection mold for a dashboard panel might cost \(100,000. If only 10,000 parts are produced, the mold cost per part would be \)10 (\(100,000 / 10,000). However, if the production volume is increased to 1,000,000 parts, the mold cost per part drops to a mere \)0.1 ($100,000 / 1,000,000). This significant reduction in unit cost makes plastic injection molding an extremely cost - effective choice for high - volume production.

Moreover, the cost of raw materials also becomes more favorable with larger production runs. Suppliers are more likely to offer volume discounts when purchasing large quantities of plastic pellets, further contributing to the overall cost - savings. In a large - scale automotive manufacturing plant that produces hundreds of thousands of vehicles annually, the cumulative cost savings from economies of scale in plastic injection - molded parts can amount to millions of dollars per year.

Low Material Waste

The plastic injection molding process is highly efficient in terms of material usage, resulting in minimal material waste. During injection molding, the molten plastic is precisely injected into the mold cavity, and the excess plastic, known as runner and gate waste, can often be recycled and reused.

Compared to other manufacturing processes like machining, where large amounts of material are removed and discarded to achieve the desired shape, injection molding is far more material - efficient. For instance, in machining a plastic part from a solid block, up to 50% or more of the original material may be wasted as chips. In contrast, in plastic injection molding, the material waste is typically less than 10% and can be even lower with advanced mold designs and proper process control.

The following table shows a comparison of material utilization rates between plastic injection molding and other common manufacturing processes:

| Manufacturing Process | Material Utilization Rate |

| Plastic Injection Molding | 90% - 95% |

| Machining | 40% - 60% |

| Casting (for plastics) | 70% - 80% |

This high material utilization not only reduces the cost of raw materials but also has environmental benefits by minimizing waste and the need for additional resource extraction. In industries where cost - control and environmental sustainability are both crucial, the low - waste nature of plastic injection mold parts production is a major advantage.

Design Flexibility

Complex Geometries Made Easy

One of the most remarkable aspects of plastic injection mold parts is their ability to bring complex geometries to life. The injection molding process allows manufacturers to create parts with intricate internal structures, undercuts, and complex outer shapes that would be extremely difficult or even impossible to achieve with other manufacturing methods.

In the aerospace industry, for Yigu Technology example, many components require complex shapes to optimize their aerodynamic performance and functionality. Turbine blades used in jet engines are often made using plastic injection molding. These blades have a complex airfoil shape with precise internal cooling channels. The injection molding process enables the production of these blades with high precision, ensuring that they can withstand the extreme temperatures and high - speed rotations within the engine. Another example is the manufacturing of complex - shaped housings for avionics equipment. These housings need to protect sensitive electronic components while also fitting into tight spaces within the aircraft. Plastic injection mold parts can be designed to have the exact shape and features required, such as internal ribs for structural support and precise cut - outs for connectors and displays.

In the field of precision instruments, the production of microscope and camera lens barrels is a great illustration of the capabilities of plastic injection mold parts. These lens barrels often have complex internal threading and precise alignment features to hold the lenses in place. The injection molding process can create these components with the necessary precision and complex geometries, allowing for the smooth operation of the lenses and high - quality optical performance.

High - Speed Production

Short Cycle Times

The plastic injection molding process is renowned for its short cycle times, making it an extremely efficient method for manufacturing plastic parts. The cycle time in plastic injection molding typically ranges from a few seconds to a couple of minutes, depending on the complexity and size of the part. For example, small and simple plastic components like bottle caps can have a cycle time as short as 5 - 10 seconds. In a high - volume production facility, a modern injection molding machine can produce hundreds or even thousands of bottle caps per hour.

When compared to other manufacturing processes, the difference in cycle times is quite significant. For instance, in traditional machining processes, creating a simple plastic part might take several minutes to even an hour, especially if multiple machining operations such as cutting, drilling, and milling are involved. In casting processes for plastics, the cycle times are often longer as well, usually ranging from 30 seconds to several minutes, due to the need for the molten plastic to solidify properly in the mold and for the mold to be opened and closed carefully.

The short cycle times in plastic injection molding are achieved through a combination of factors. The high - pressure injection of molten plastic into the mold cavity allows for quick filling, and the efficient cooling systems built into the molds help the plastic solidify rapidly. Additionally, modern injection molding machines are highly automated, with fast - acting hydraulic or electric systems that can quickly open and close the molds, eject the finished parts, and prepare for the next injection cycle.

Meeting High - Volume Demands

In today's global market, the demand for various products is often extremely high, and plastic injection mold parts play a crucial role in meeting these high - volume demands. Take the consumer electronics market as an example. During the holiday season or when a new smartphone model is released, the demand for plastic components such as phone cases, internal frames, and button covers can skyrocket. A popular smartphone model might sell millions of units within a few months.

Plastic injection molding facilities can ramp up production to meet such demands. With multiple injection molding machines operating 24/7, they can produce a vast number of plastic injection mold parts in a short period. A large - scale injection molding factory might have hundreds of injection molding machines, each capable of producing a certain number of parts per hour. For example, if each machine can produce 500 plastic phone cases per hour, and there are 200 machines in operation, the factory can produce 100,000 phone cases per hour. This high - volume production capability ensures that manufacturers can keep up with the market demand and get their products to consumers in a timely manner.

Moreover, the ability to produce parts with consistent quality in large quantities is essential. Plastic injection mold parts' high - precision and repeatability features, as mentioned earlier, ensure that every part is of the same high quality, whether it's the first part produced or the millionth one. This consistency is highly valued by manufacturers as it reduces the risk of product recalls and ensures customer satisfaction. In industries where high - volume production is the norm, such as the automotive, consumer goods, and electronics industries, plastic injection mold parts have become the go - to solution for efficient and reliable manufacturing.

Yigu Technology's Perspective

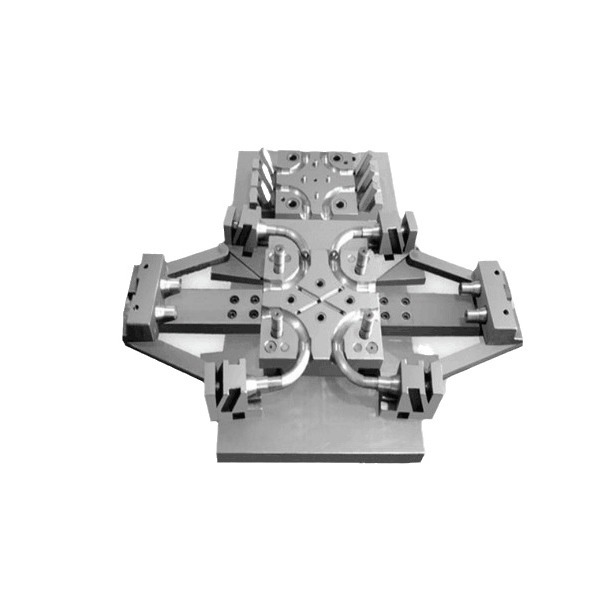

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the significance of plastic injection mold parts in manufacturing. Our professional team, armed with in - depth industry knowledge and rich experience, can accurately analyze customers' needs. We have advanced equipment and technologies, which enable us to design and manufacture high - quality plastic injection molds.

For us, whether it's high - precision parts for medical devices or large - scale components for industrial equipment, we can provide customized solutions. We focus on every detail, from mold design to production, to ensure that the plastic injection mold parts we produce not only meet high - quality standards but also contribute to high - efficiency production processes. Our goal is to help customers improve product competitiveness in the market through excellent plastic injection mold parts.

FAQs

What types of plastics are commonly used in injection mold parts?

Several types of plastics are frequently used in injection mold parts. ABS (Acrylonitrile Butadiene Styrene) is popular due to its excellent impact resistance, good strength, and heat resistance. It can be easily molded into complex shapes and is often used in automotive parts like dashboards, and in electronic device housings such as those for smartphones and laptops. PP (Polypropylene) offers high chemical resistance, good flexibility, and is lightweight. It is widely used in food packaging, as it is non - toxic, and in automotive interior components. For example, many car seat covers are made of PP - based materials. PE (Polyethylene) comes in different densities (HDPE - High - Density Polyethylene and LDPE - Low - Density Polyethylene). HDPE is known for its strength and rigidity, and is used in products like plastic pipes for plumbing systems. LDPE is more flexible and is often used in plastic bags and some types of containers. PVC (Polyvinyl Chloride) has good flame - retardant properties and is used in applications where fire safety is crucial, such as in electrical cable insulation. It is also used in construction materials like window frames due to its durability.

How can I ensure the quality of plastic injection mold parts?

To ensure the quality of plastic injection mold parts, several aspects need to be considered. First, raw material selection is crucial. Choose high - quality plastics from reliable suppliers, and check for material certifications and quality control reports. For example, if using ABS plastic, ensure it meets the required standards for impact resistance and heat stability. Second, mold design must be precise. A well - designed mold with proper draft angles, uniform wall thickness, and efficient cooling channels is essential. This helps in preventing issues like warping, shrinkage, and incomplete filling of the mold cavity. Third, monitor the production process closely. Control parameters such as injection pressure, temperature, and cycle time. For instance, maintaining the correct injection pressure ensures that the molten plastic fills the mold evenly. Finally, conduct thorough quality inspections. Use techniques like dimensional measurement, visual inspection for surface defects, and functional testing if applicable. For parts with strict dimensional requirements, use precision measuring tools like coordinate measuring machines (CMMs).

Can plastic injection mold parts be recycled?

Yes, plastic injection mold parts can be recycled. Mechanical recycling is a common method, where the plastic parts are shredded, cleaned, and melted to be remolded into new products. This is suitable for many common plastics like ABS, PP, and PE. For example, recycled HDPE can be used to make new plastic pipes. Chemical recycling can also be employed, especially for more complex plastics or when higher - quality recycled materials are needed. In chemical recycling, the plastic is broken down into its basic chemical components, which can then be used to synthesize new plastics. Recycling plastic injection mold parts is not only beneficial for reducing waste and conserving resources but also for minimizing the environmental impact associated with plastic production. By recycling, we can reduce the need for virgin plastic production, which requires significant amounts of energy and raw materials.

Conclusion

In conclusion, plastic injection mold parts offer a multitude of benefits that have revolutionized the manufacturing industry. Their high - precision manufacturing capabilities ensure that parts meet the strictest dimensional accuracy requirements, with exceptional repeatability in production, which is crucial for industries that demand large - scale production of consistent components.

The cost - efficiency of plastic injection mold parts, through economies of scale and low material waste, makes them an attractive choice for manufacturers looking to reduce production costs without sacrificing quality. The design flexibility they provide, allowing for the creation of complex geometries and a high degree of customization, enables manufacturers to bring innovative and unique products to the market.

Moreover, the high - speed production capabilities, with short cycle times and the ability to meet high - volume demands, ensure that manufacturers can keep up with the fast - paced market requirements.

As we look to the future, the role of plastic injection mold parts in manufacturing will only become more significant. With the continuous advancement of technology, we can expect even more improvements in the quality, efficiency, and versatility of plastic injection mold parts. Manufacturers are encouraged to fully leverage these advantages to enhance their production efficiency and product competitiveness, and to stay ahead in the highly competitive global manufacturing landscape.